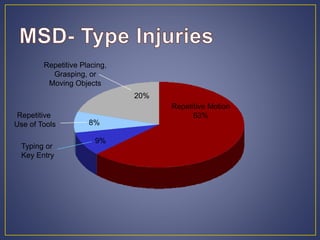

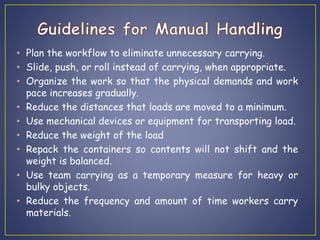

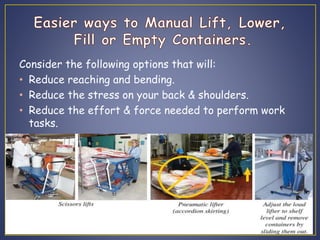

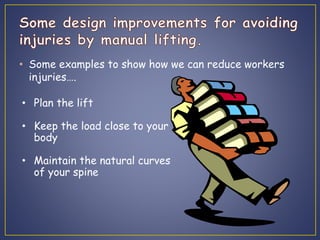

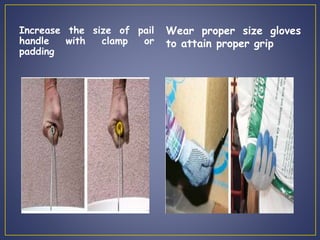

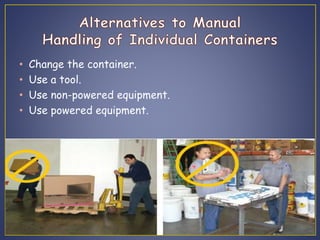

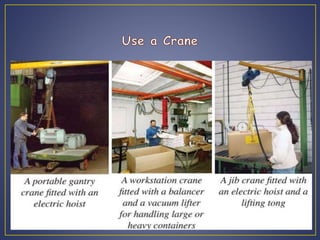

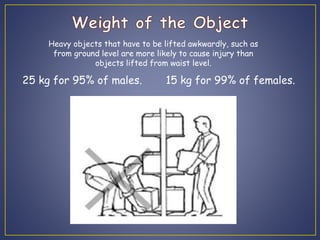

The document discusses manual handling tasks and how to prevent musculoskeletal injuries in the workplace. It notes that 37% of workplace injuries are due to manual handling tasks. Some key risks include lifting heavy objects, repetitive motions, awkward postures like bending or twisting, and poorly designed workspaces or equipment. The document provides recommendations to address these risks, such as using lifting aids, redesigning workspaces, providing training, and reorganizing tasks to reduce risk of injuries.