Embed presentation

Download to read offline

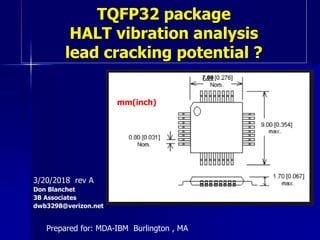

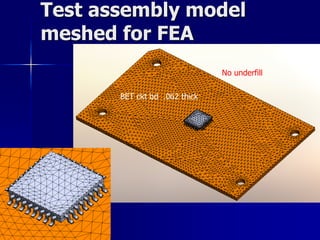

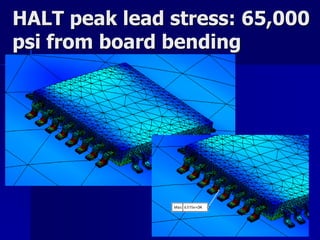

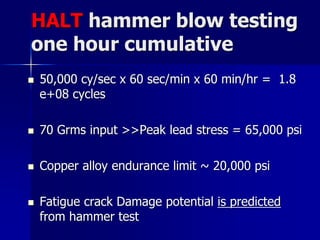

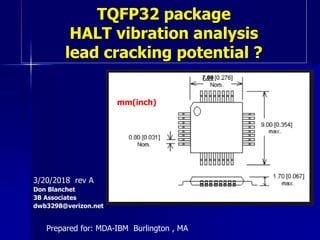

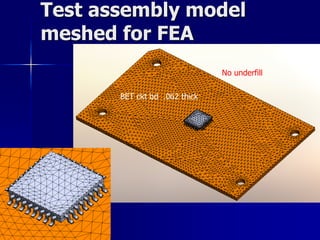

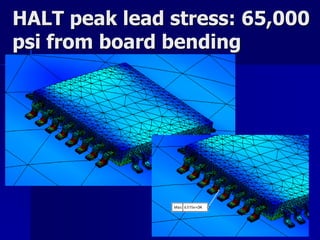

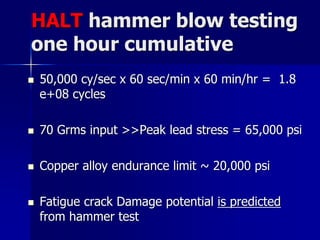

The document analyzes the potential for lead cracking in a TQFP32 package under vibration testing. A Solidworks simulation modeled the package and circuit board to determine major resonances and peak lead stresses. The simulation found a package resonance at 50kHz from lead frame and package bending. HALT testing was predicted to induce a peak lead stress of 65,000 psi, above the copper alloy's endurance limit of 20,000 psi, indicating a potential for fatigue cracking in the leads from the hammer blows.