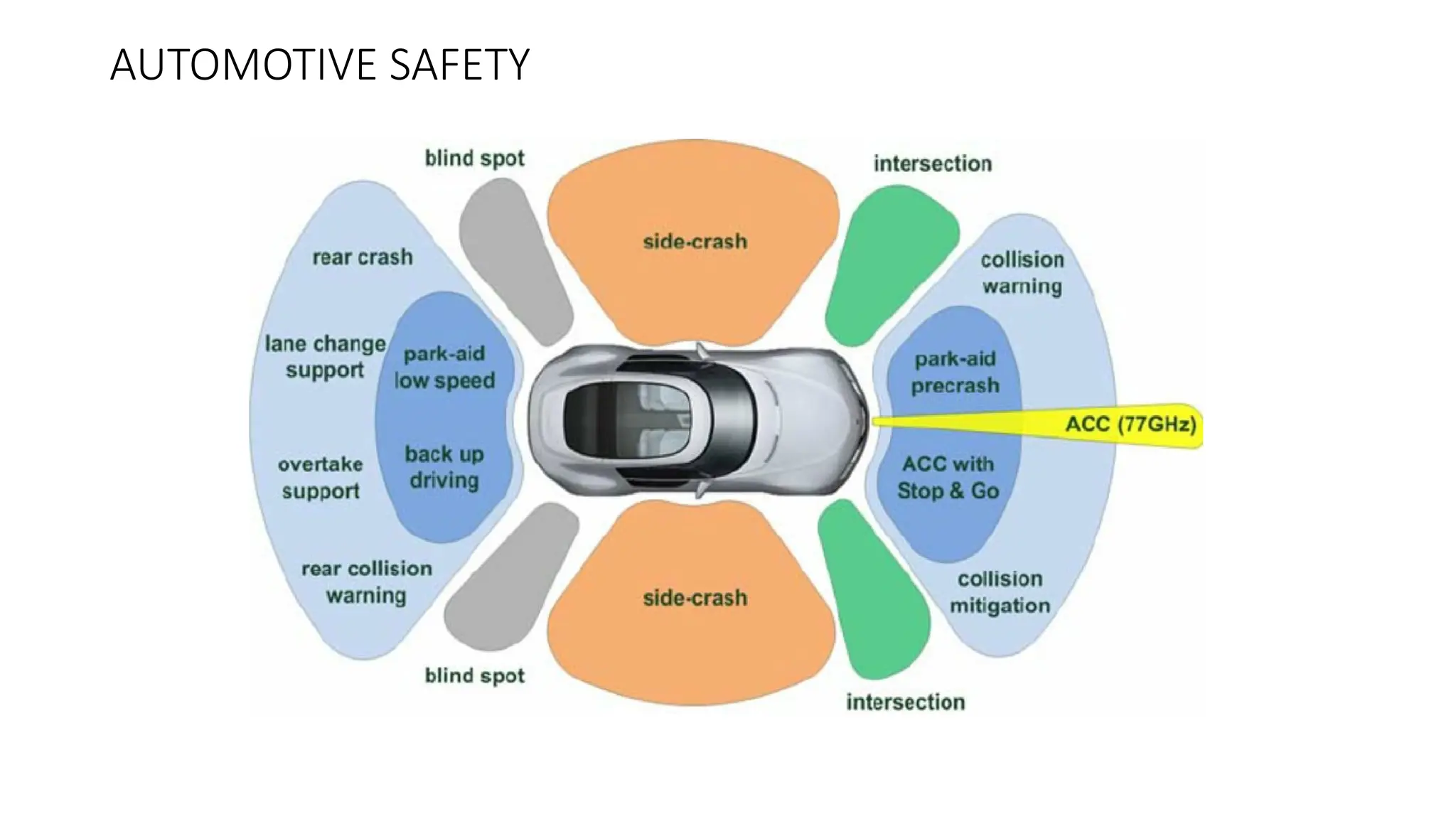

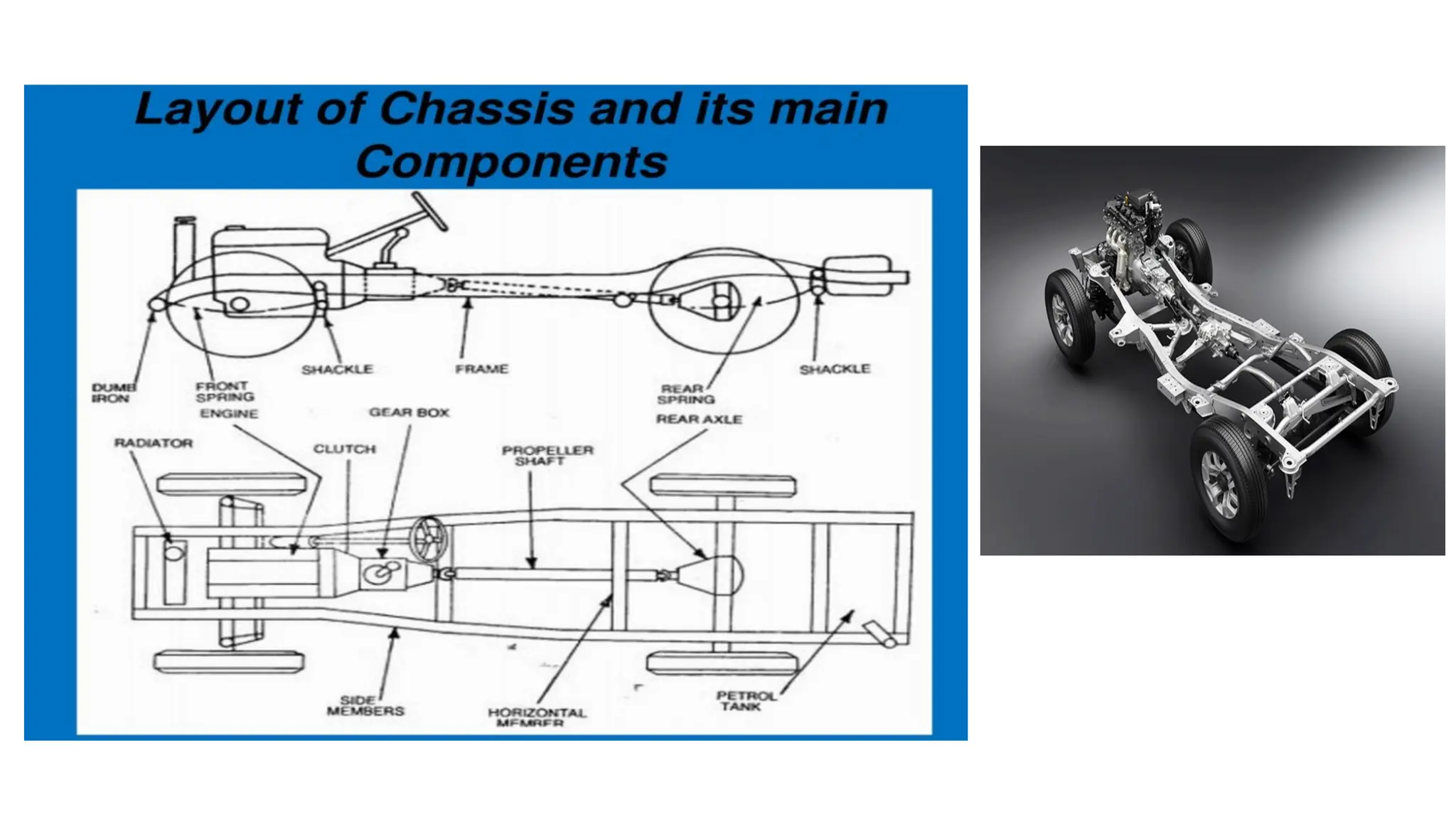

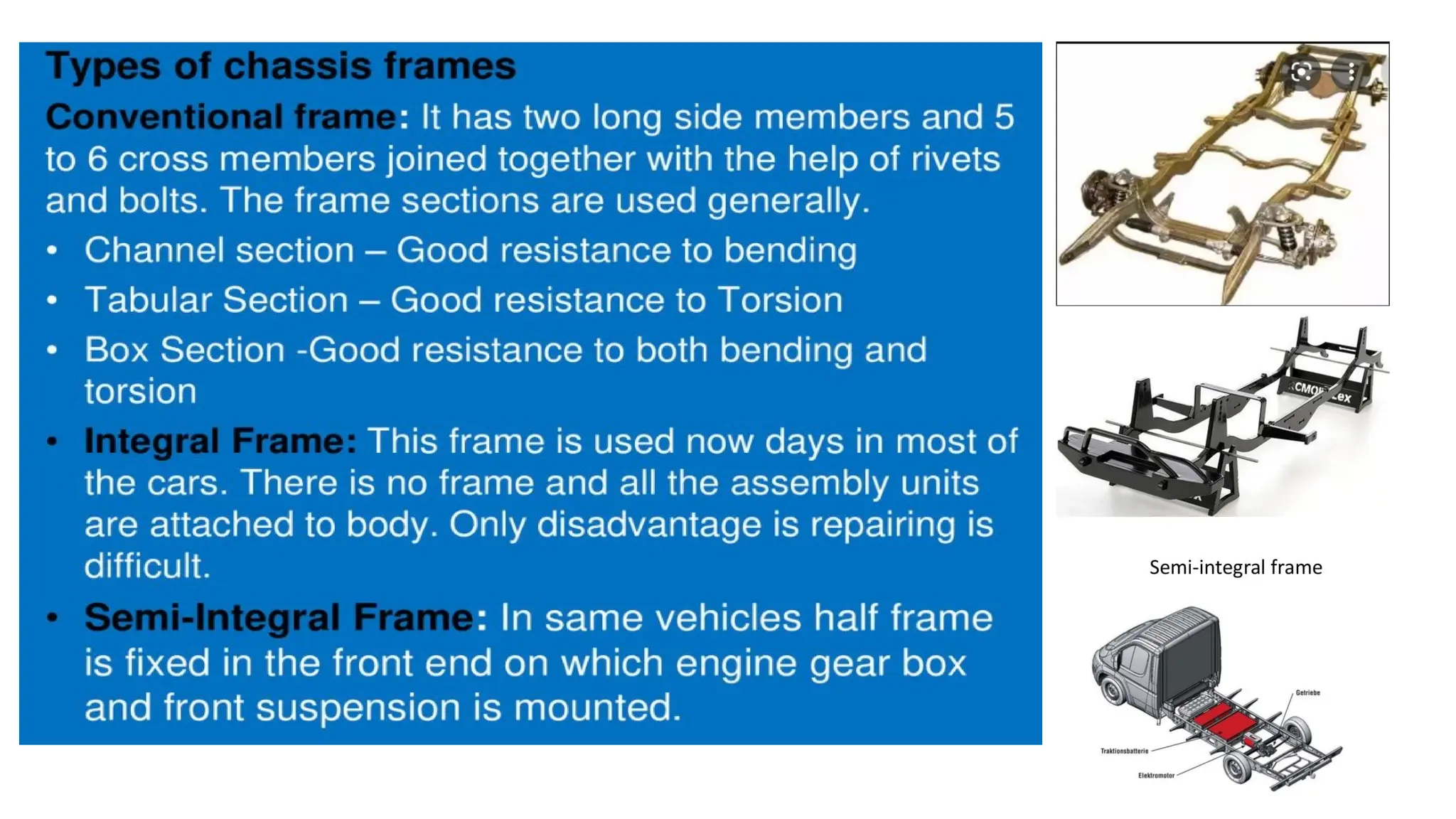

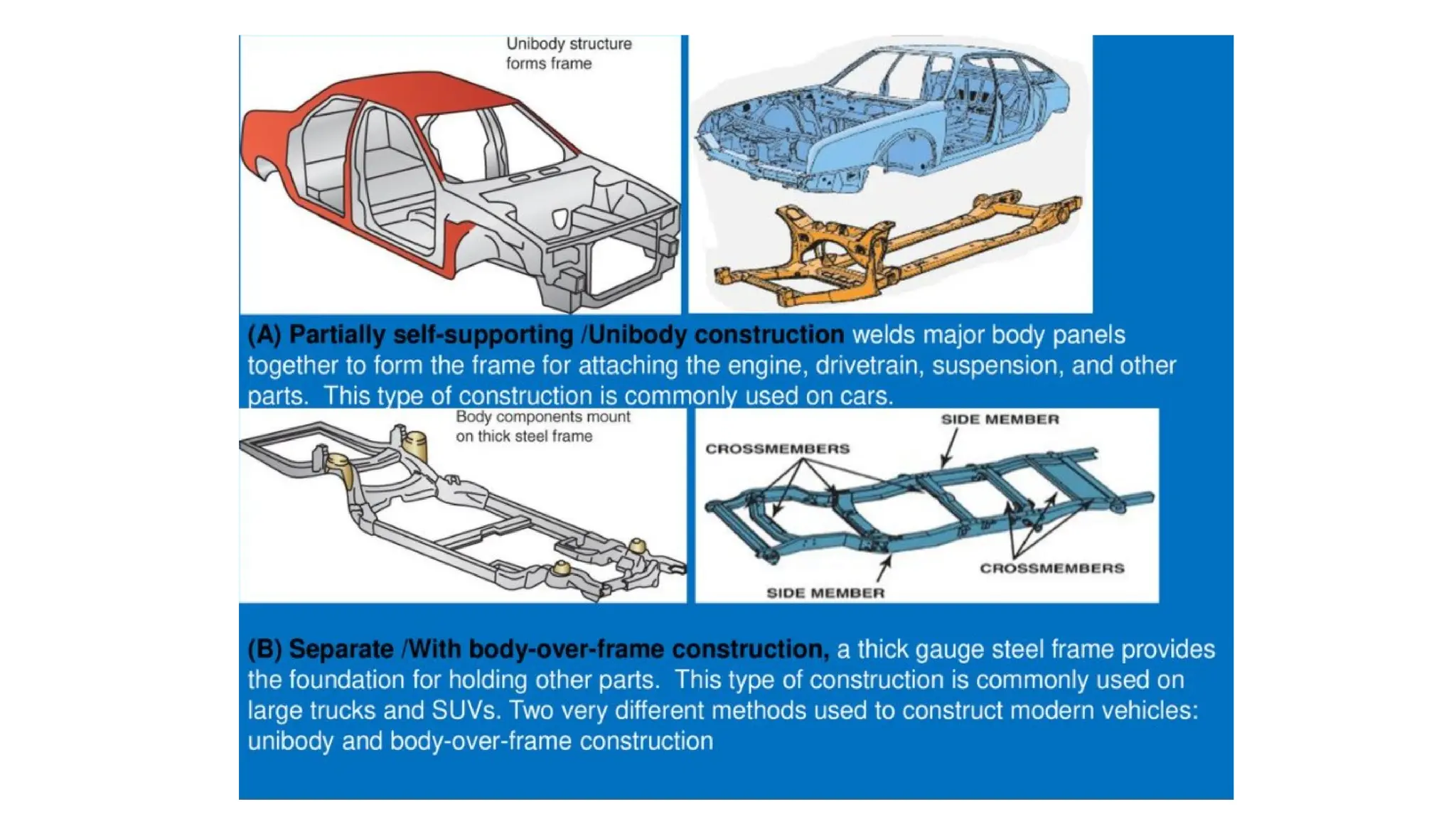

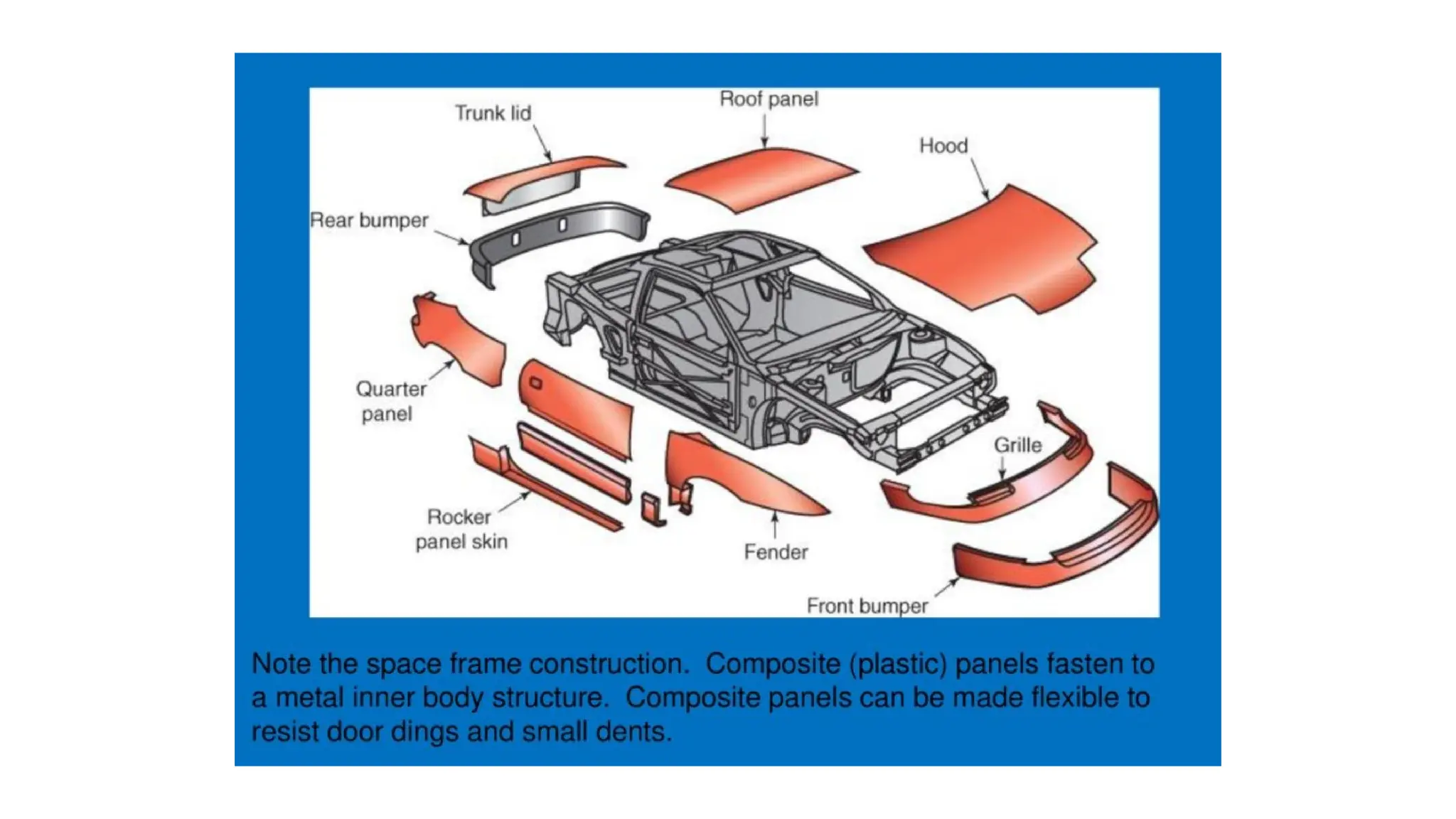

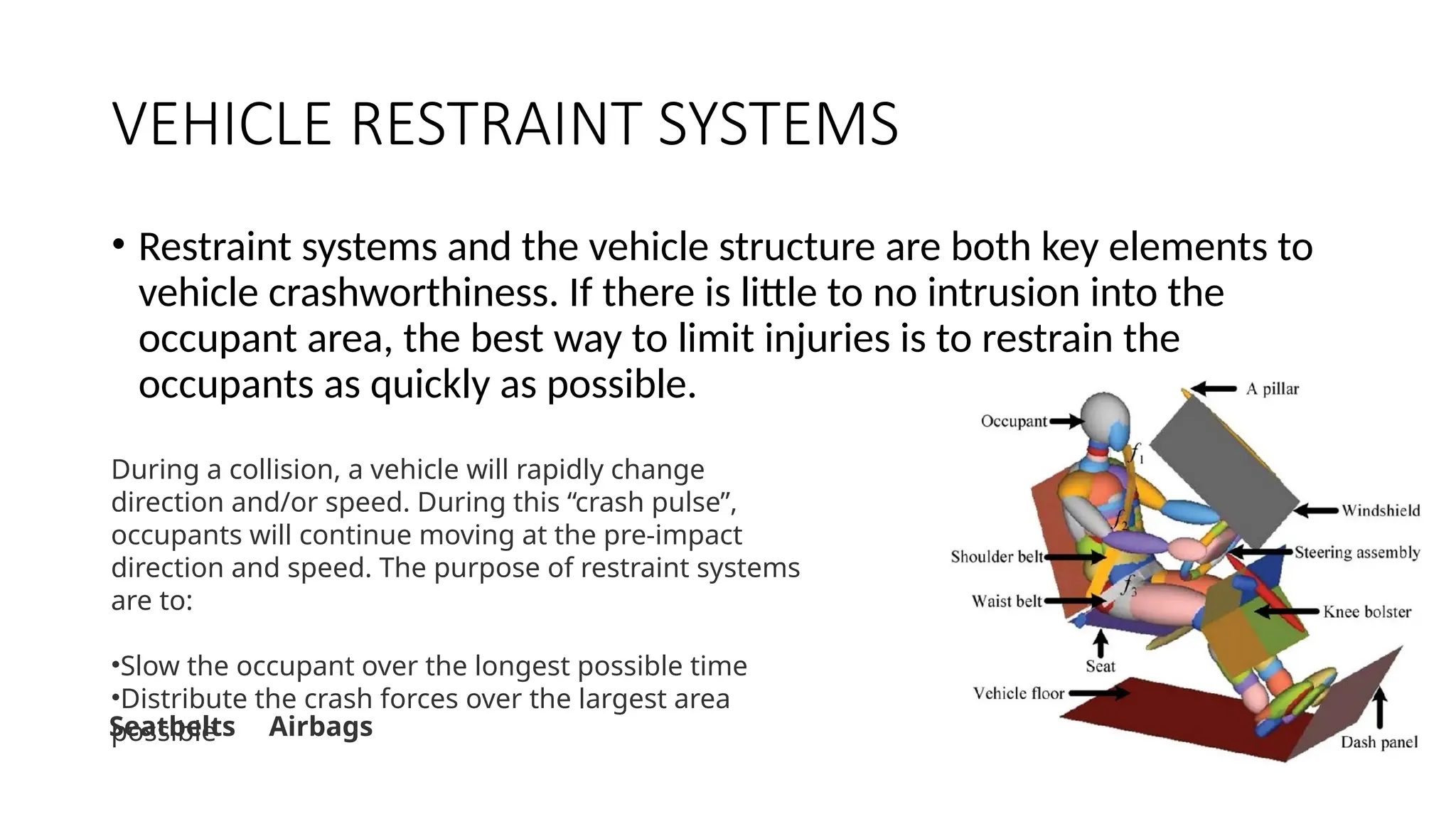

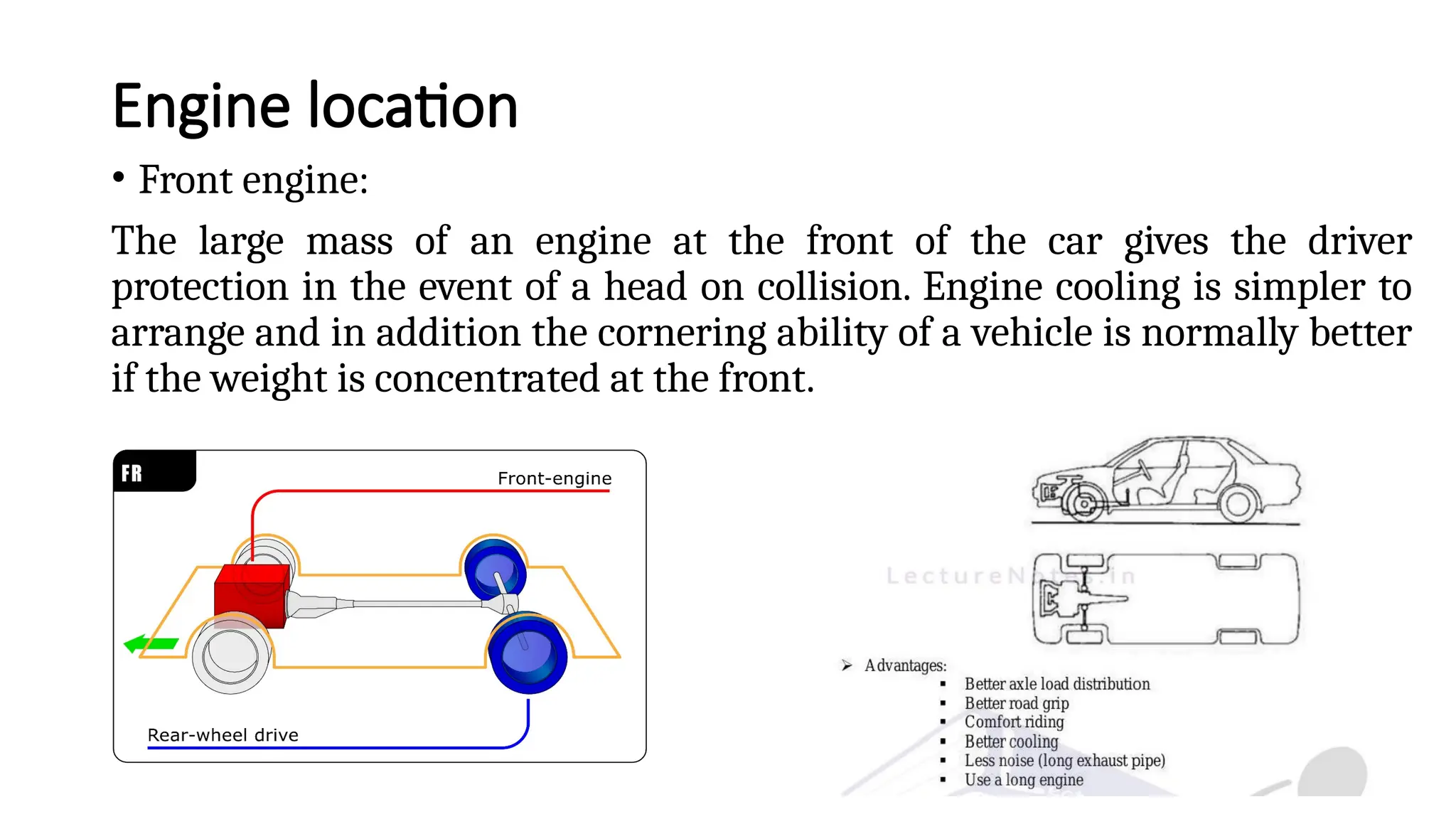

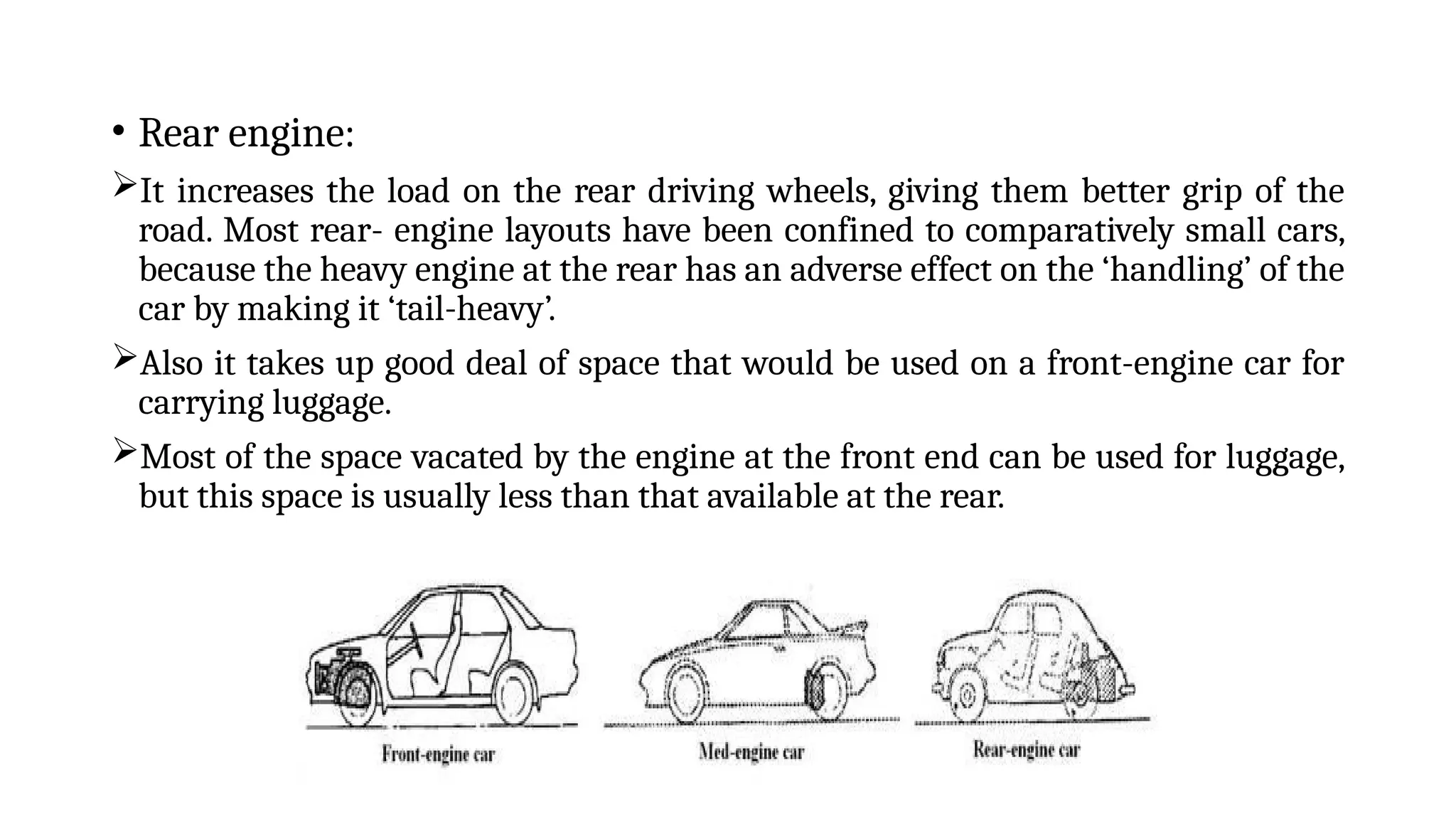

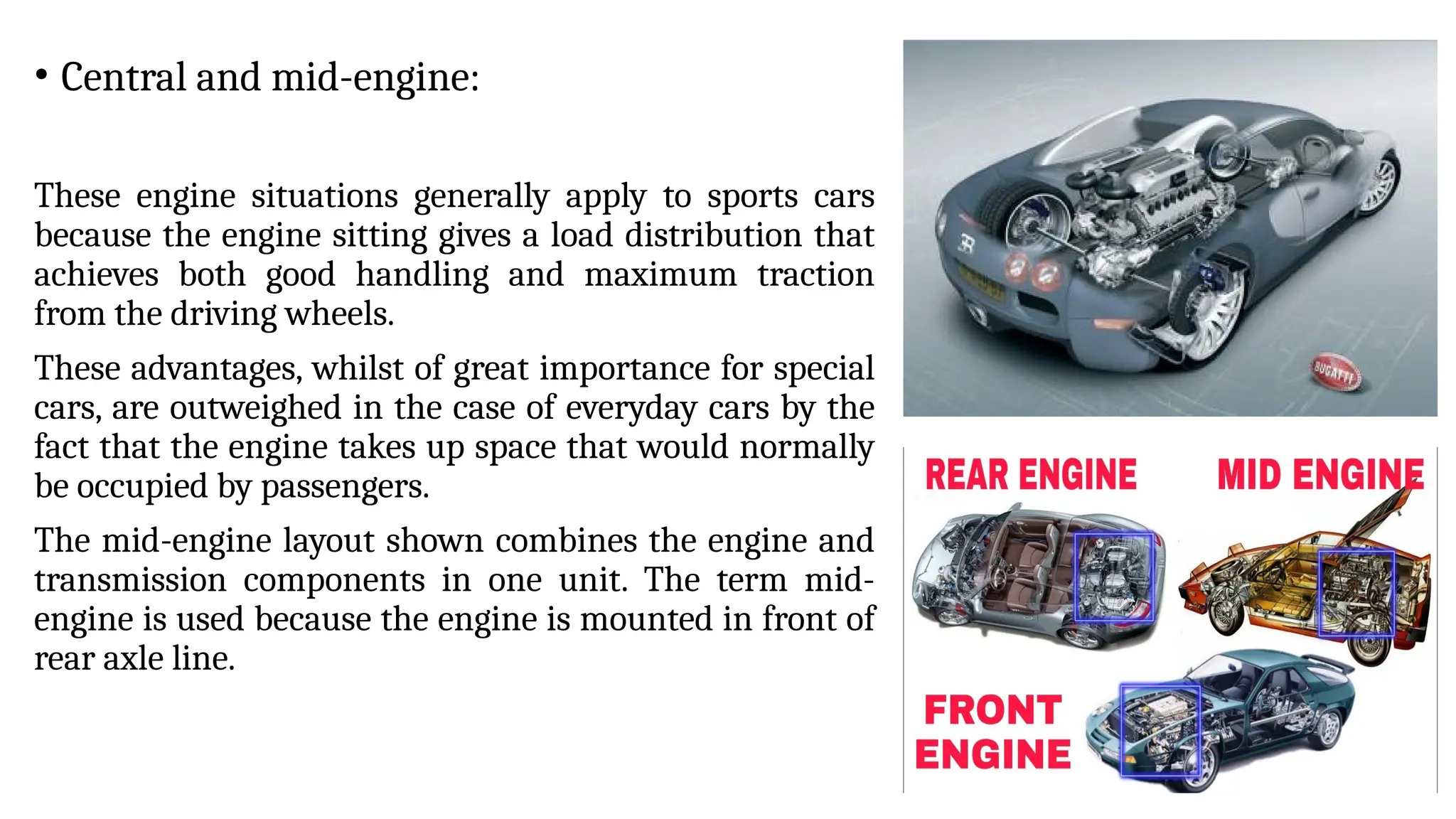

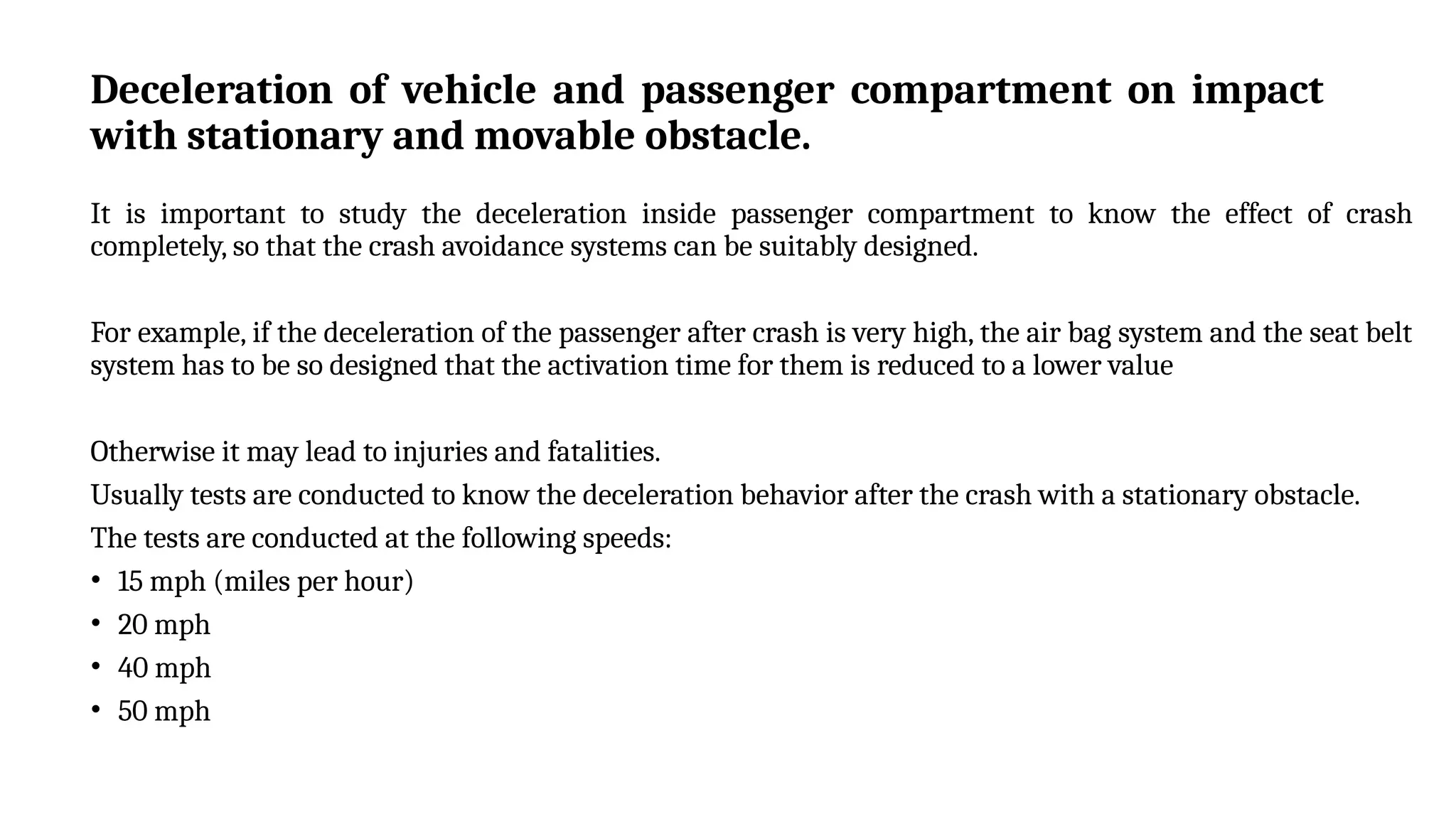

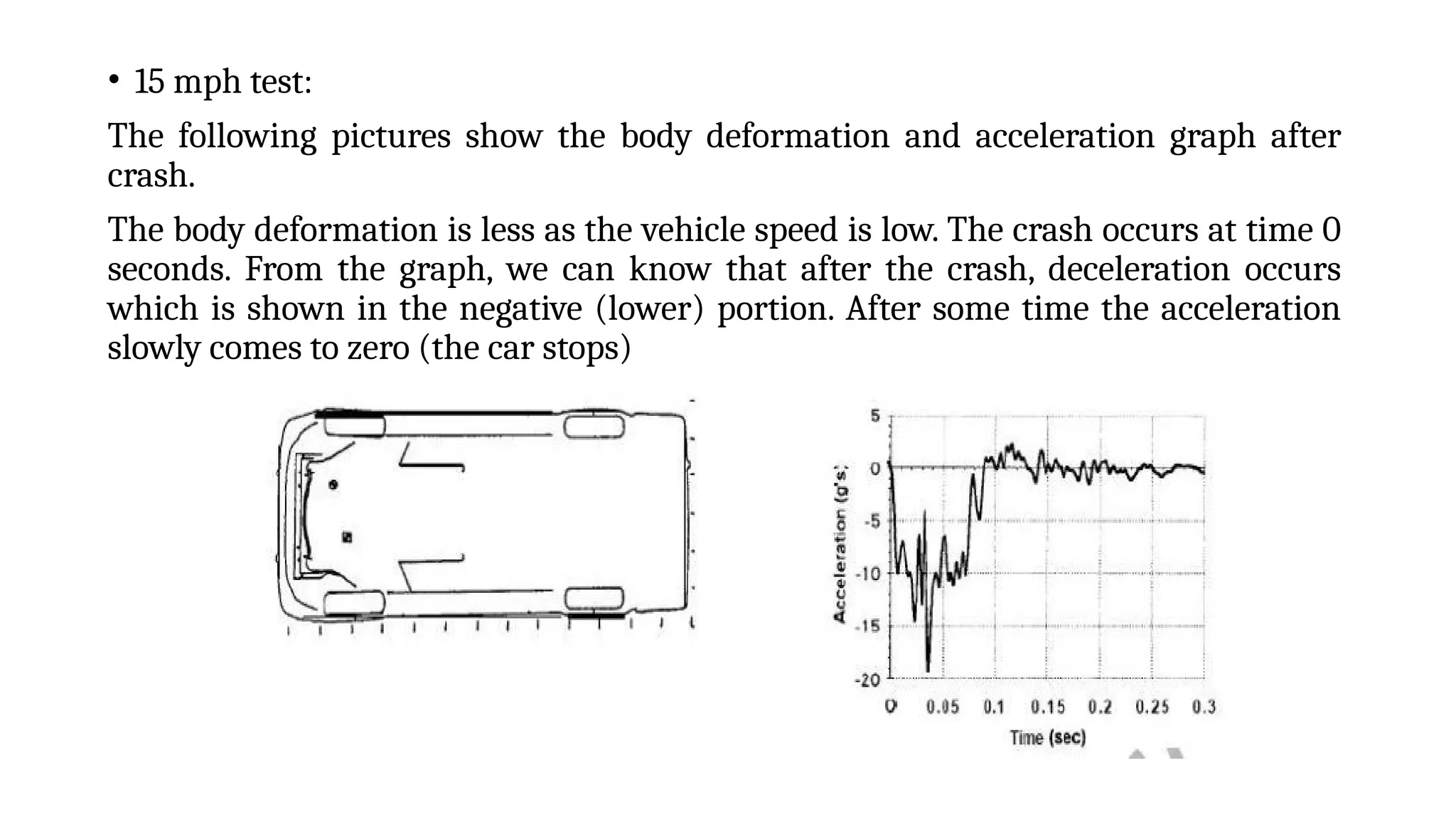

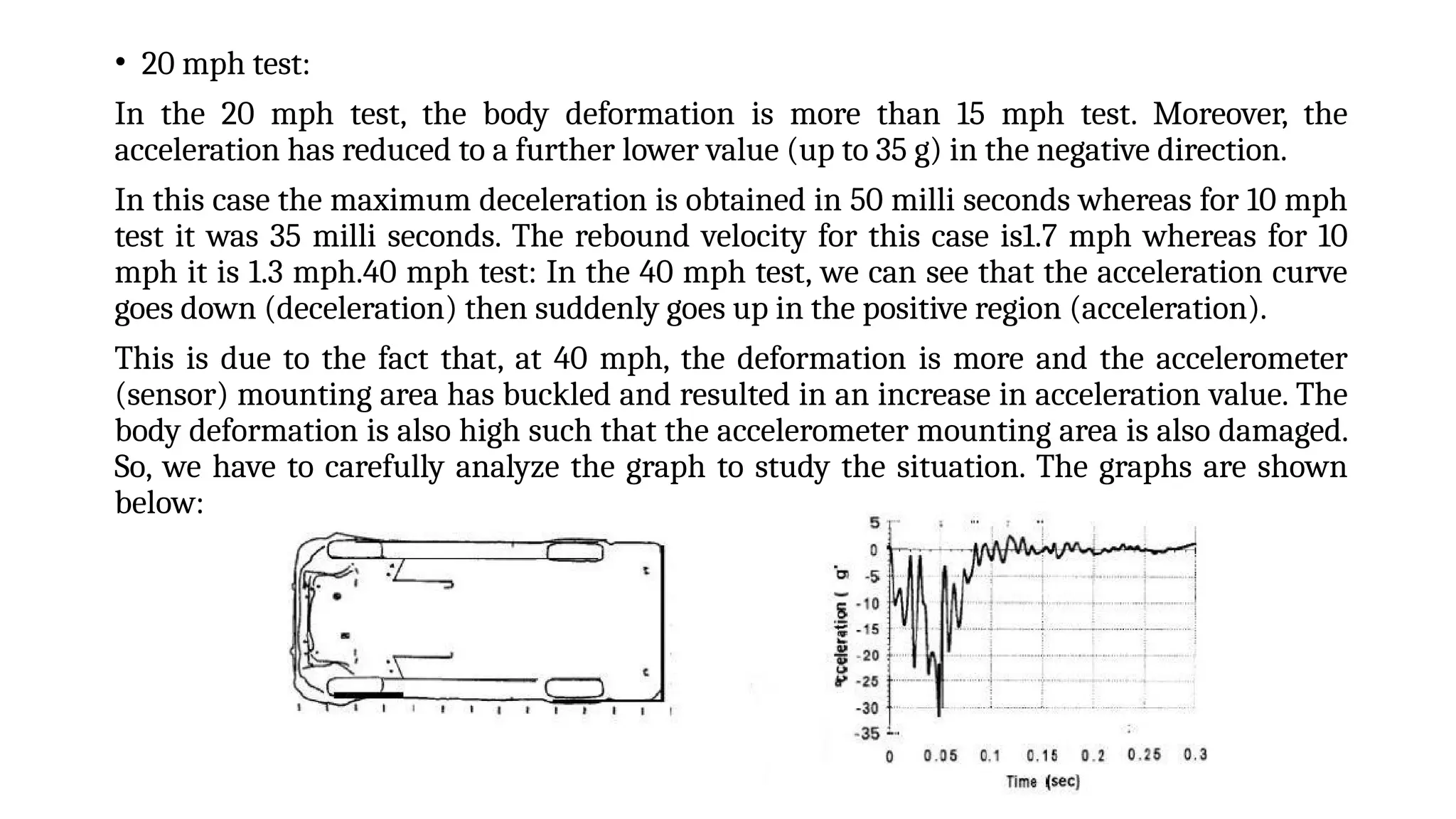

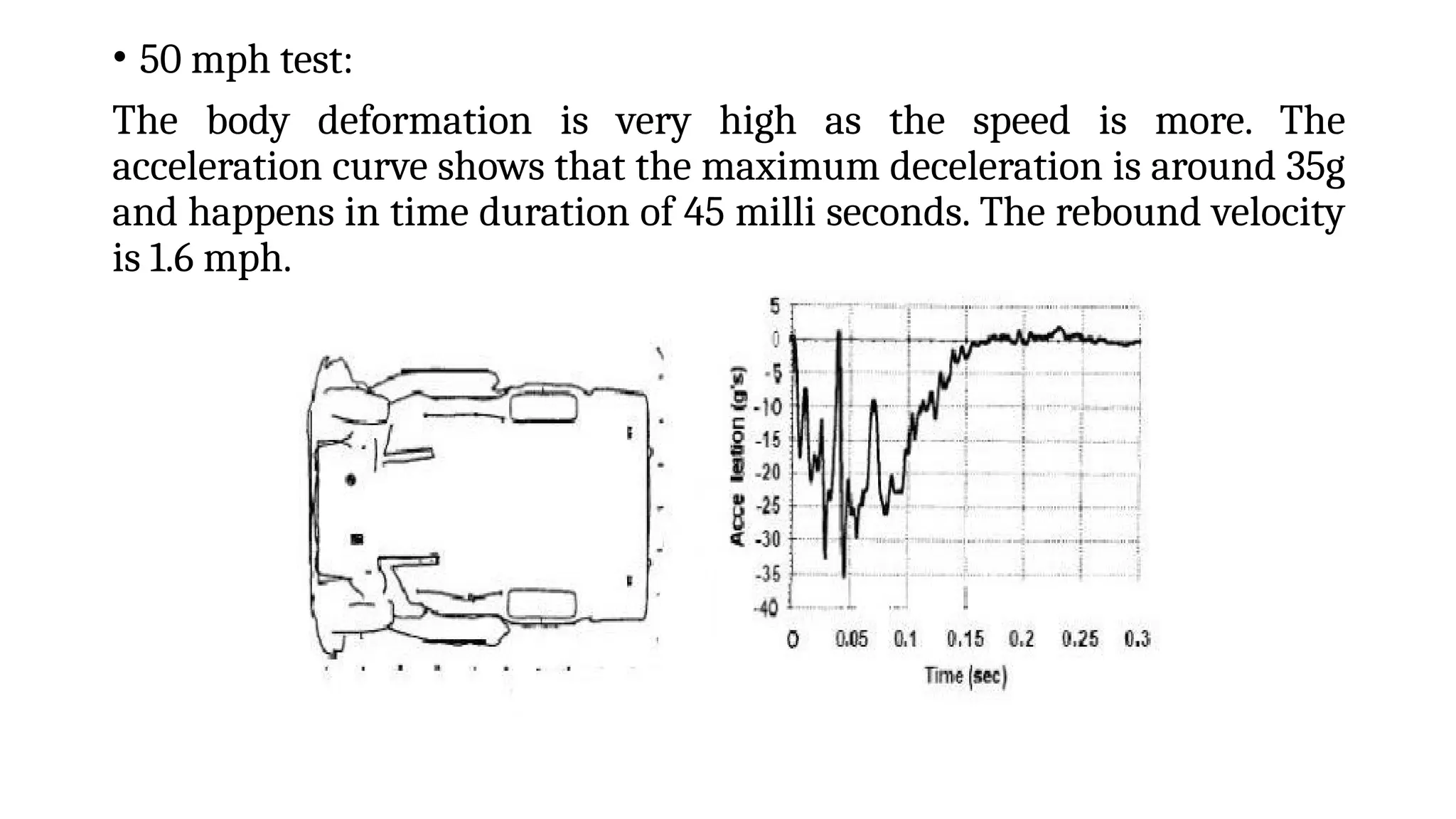

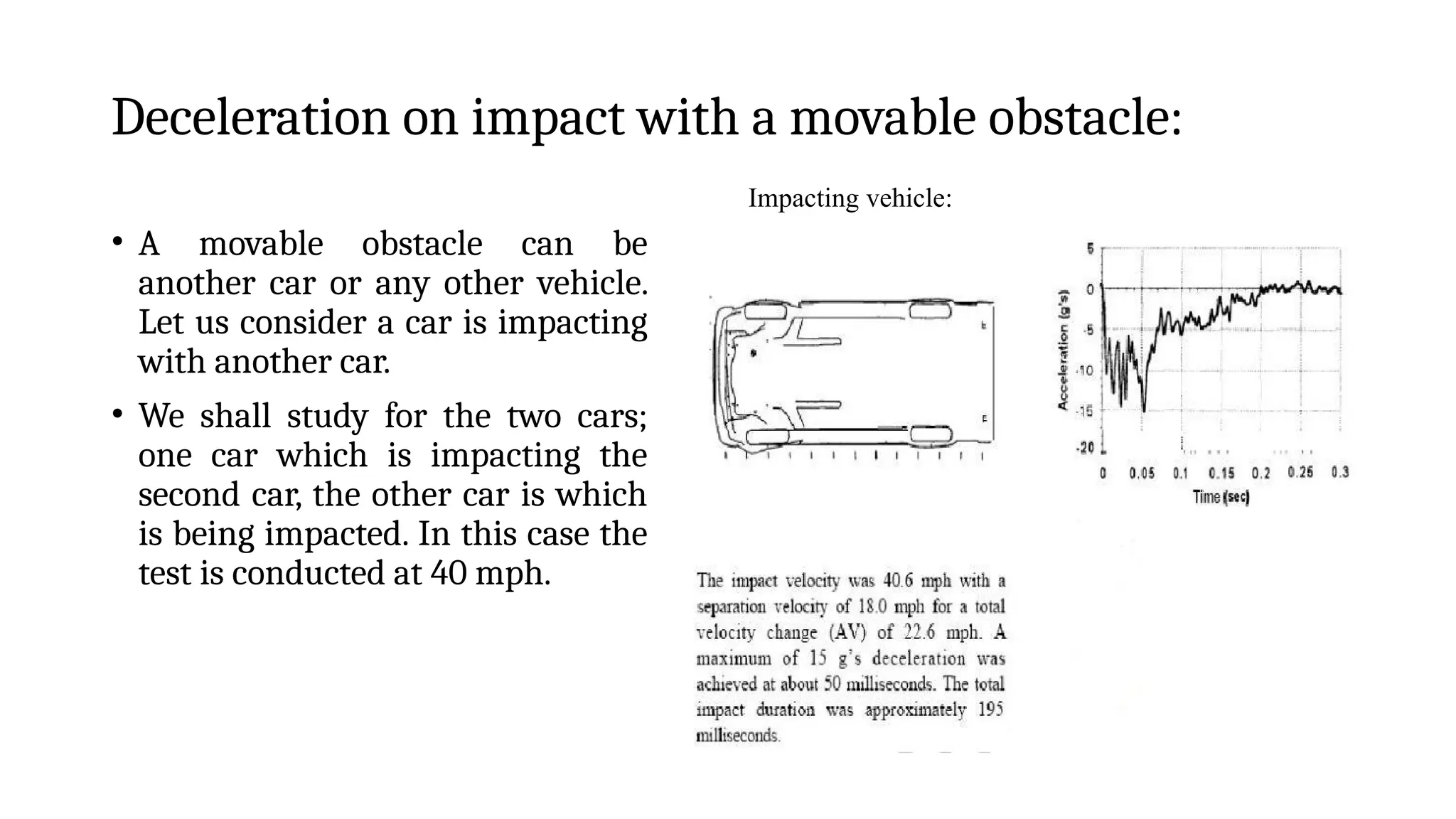

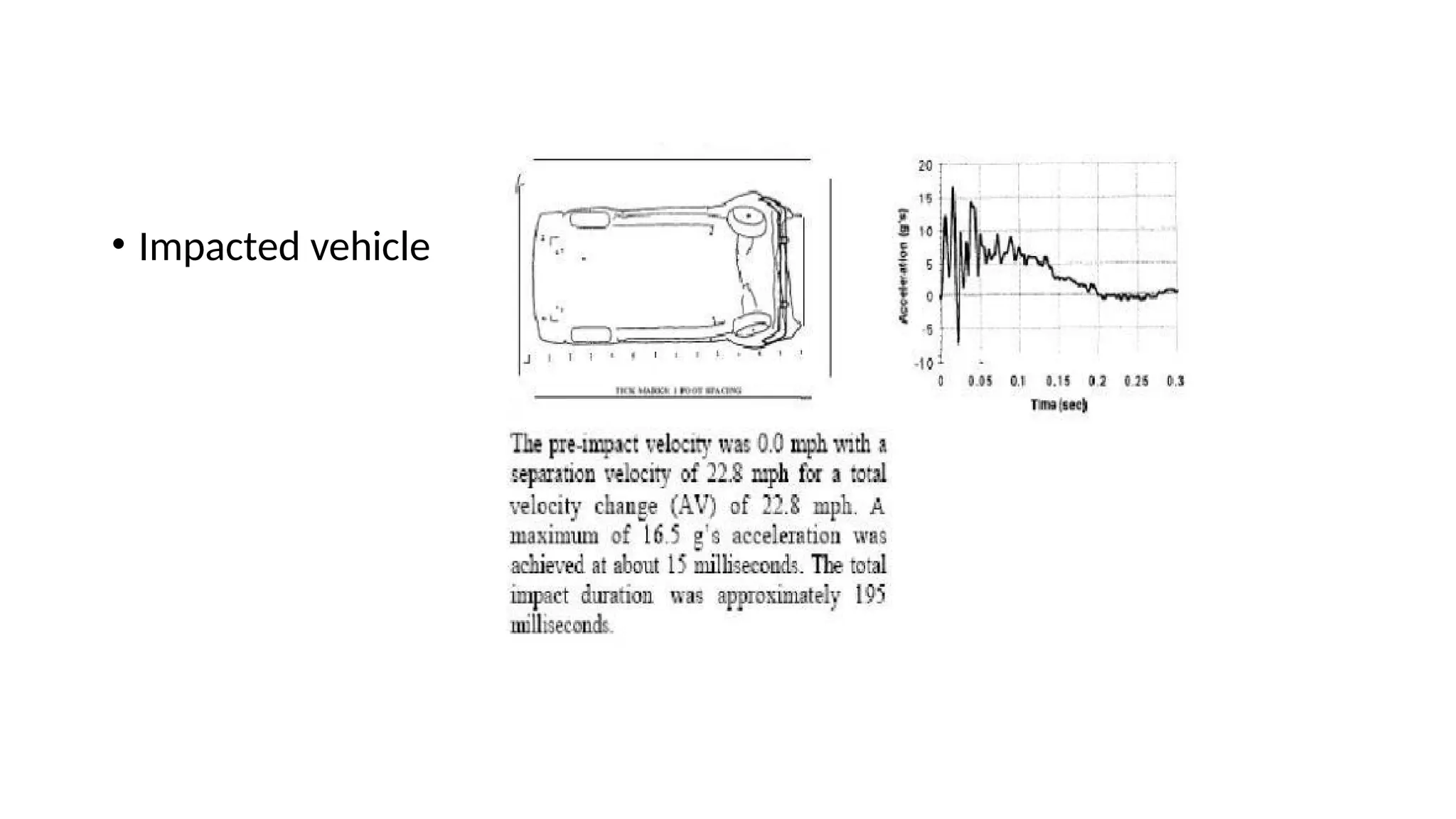

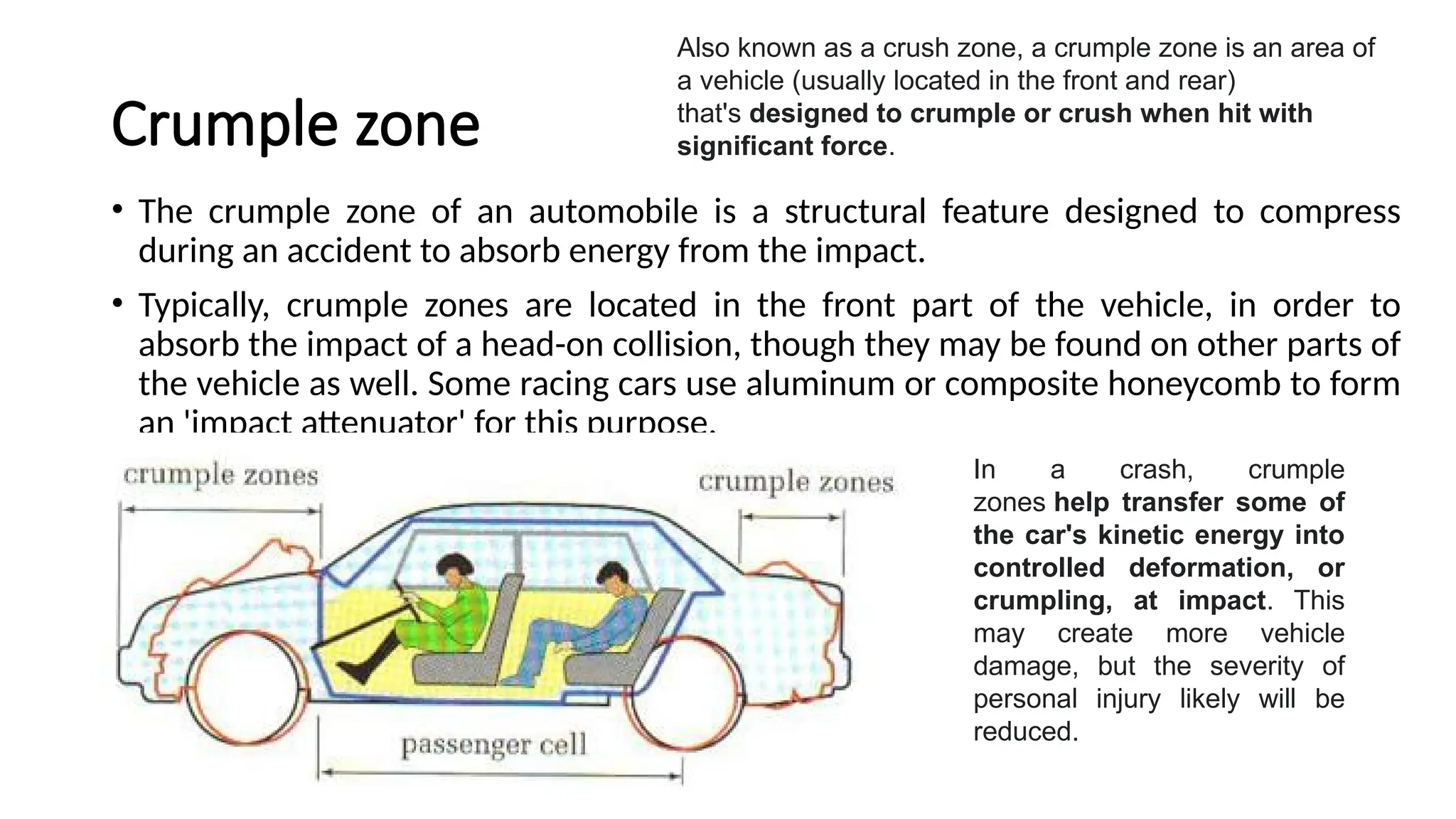

The document discusses automotive safety, focusing on the design of vehicles to minimize injuries during accidents through active and passive safety systems. It covers topics such as crumple zones, vehicle body structures (body-on-frame and unibody), crash avoidance systems, and the importance of restraint systems to protect occupants. Additionally, it delves into engineering principles regarding kinetic energy, engine placement, and the effectiveness of safety technologies like airbags and seatbelts.