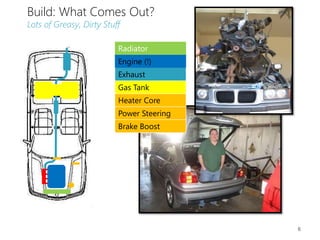

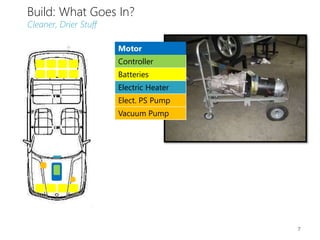

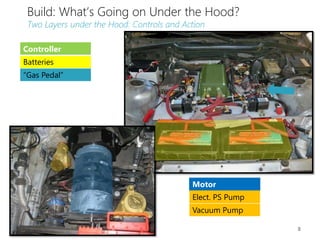

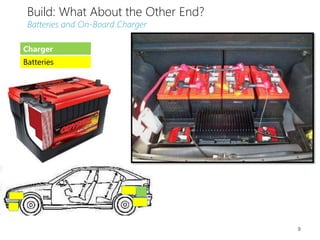

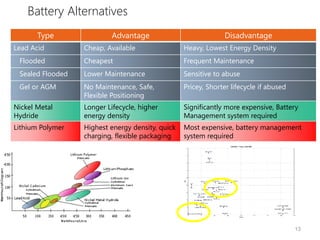

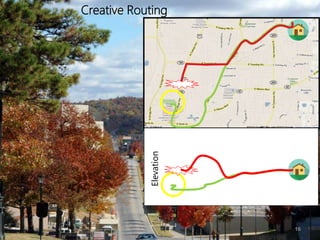

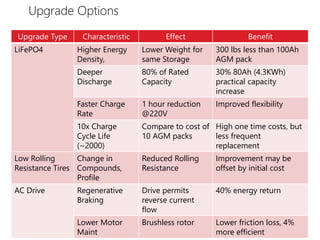

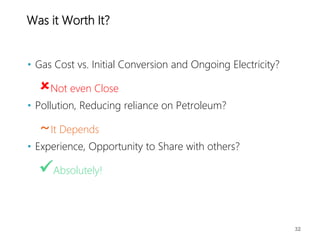

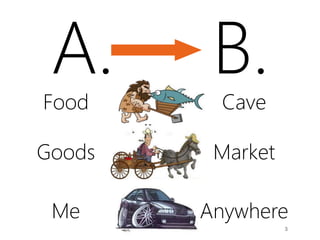

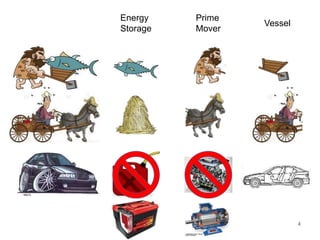

This document provides an overview of electric vehicles and discusses some key considerations for life with an electric car. It covers choices regarding vehicle components like batteries and motors, ways to reduce range anxiety through efficient driving habits and charging options, and potential upgrade options to improve performance over time. While concerns remain regarding battery life and costs, as well as challenges in transitioning auto manufacturing, the outlook is positive as infrastructure expands and myths are dispelled. The owner found converting their BMW to electric power to be worthwhile for reducing emissions and costs, as well as for the experience of sharing their vehicle with others.

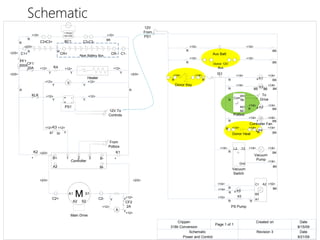

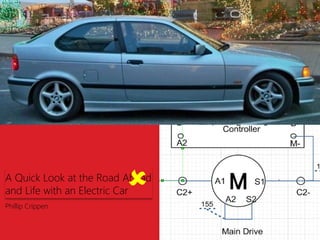

![Build: e318ti

Donor: 1997 BMW 318ti, 207k miles, purchased Oct 2008

Factory Converted

Engine 4cyl 1.9l 9inch DC

Max HP 103 HP @

6000RPM

100HP @

5000RPM

Max Torque 133 ft-lb @

4300RPM

115 @ 500A ,

0-5000RPM

Max RPM 6500 5000

Top Speed 140mph 80mph [108?]

Curb Weight 2950 lbs 3100 lbs

5](https://image.slidesharecdn.com/emwpost-171215175657/85/Life-with-a-homebrew-Electic-Vechicle-5-320.jpg)