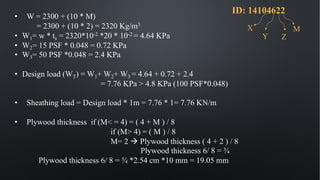

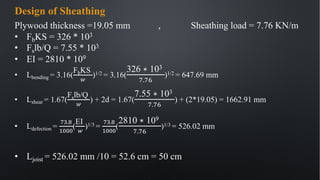

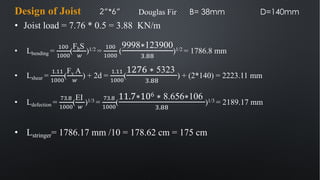

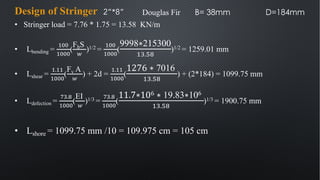

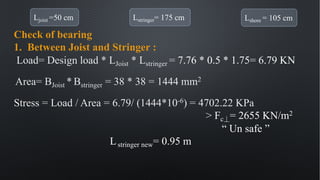

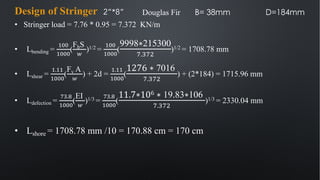

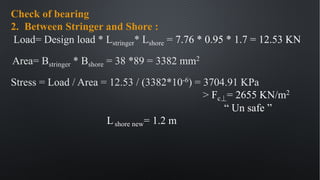

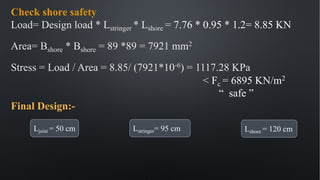

This document summarizes the design of a wood floor system. It calculates loads and dimensions for joists, stringers, and shoring. Initial designs resulted in unsafe bearing stresses between the joist/stringer and stringer/shore. Reducing the stringer length to 0.95m and shore length to 1.2m resulted in a final design with safe bearing stresses.