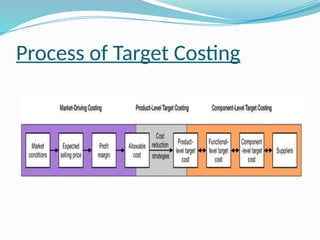

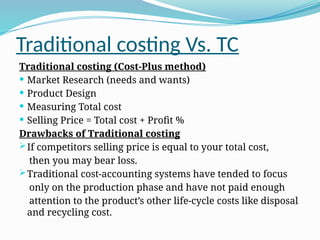

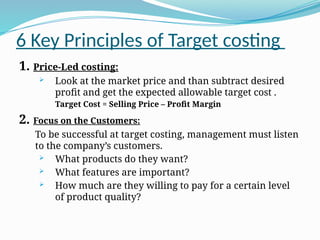

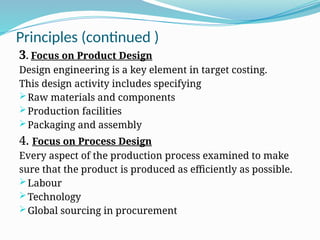

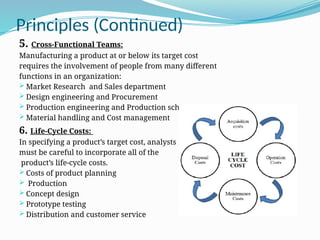

Target costing is a cost management approach aimed at reducing product life-cycle costs through market-driven pricing, customer-focused design, and cross-functional collaboration. Key principles include price-led costing, customer focus, and consideration of life-cycle costs, making it especially effective during the planning stages of new products. While it offers advantages like competitive edge and customer satisfaction, challenges include time consumption and potential organizational conflicts.