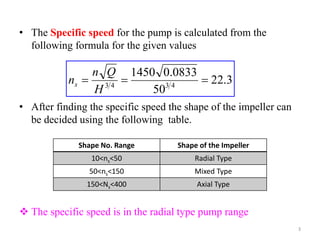

This document provides steps to design the impeller of a radial water pump. Key details include:

- The specific speed is calculated to be 51.9, indicating a radial type impeller shape.

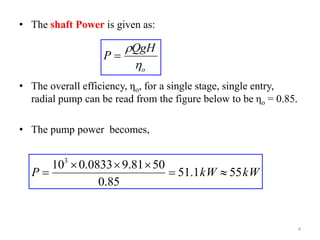

- The pump power is calculated to be 55 kW.

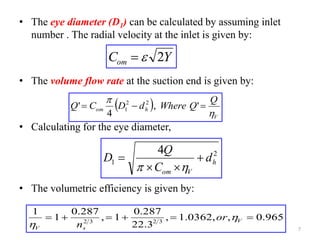

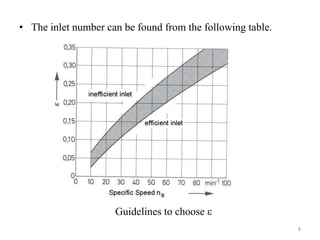

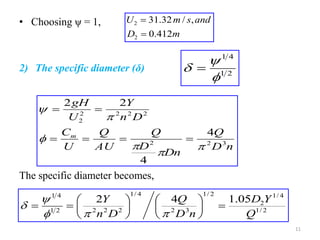

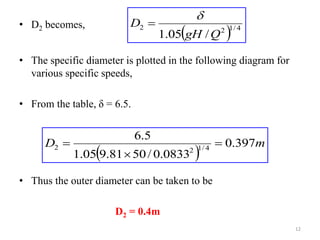

- Dimensions like the shaft diameter, eye diameter, and outer diameters are determined using formulas involving flow rate, head, speed and material properties.

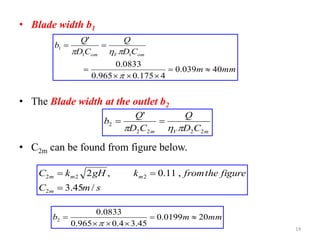

- Blade width, angles and number of blades are estimated from standard reference diagrams.