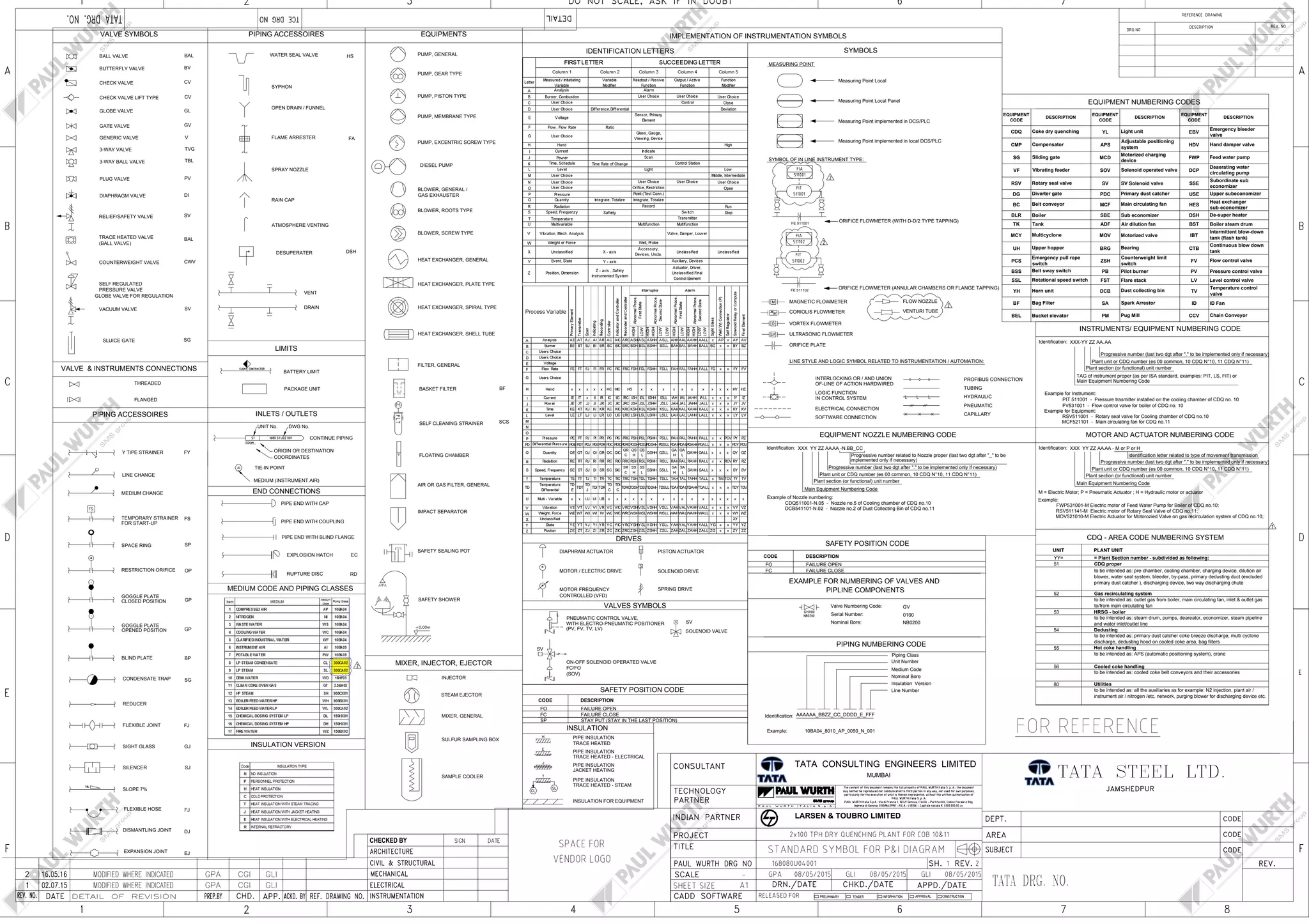

This document provides piping, instrumentation, and equipment symbols and numbering codes for a coke dry quenching plant. It includes symbols for various pumps, valves, heat exchangers, filters, blowers, instruments, and other components. The document also outlines equipment, instrument, motor/actuator, and nozzle numbering codes that include plant section numbers, tags, and progressive numbers for identification.