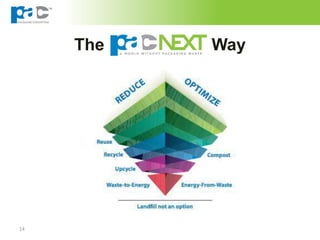

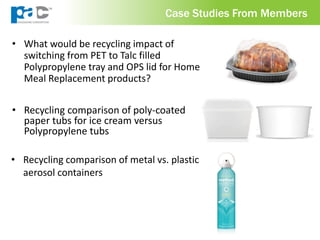

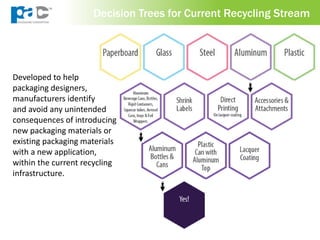

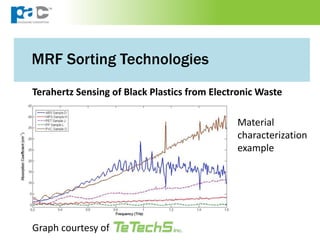

This document summarizes a presentation by CoPPAC (Canadian Packaging Coalition) from October 2015. It discusses how CoPPAC connected over 3,000 people in 2014 through various tours, seminars, and events. It also outlines CoPPAC's visions and goals related to packaging waste reduction and food waste solutions. Key trends like the circular economy are discussed. Challenges for packaging recyclability like multi-layer laminates and black plastics are also summarized. The document promotes CoPPAC's packaging and food waste innovation awards and new interactive website resources.