The document discusses sustainable manufacturing, focusing on optimizing parameters in the turning process to enhance productivity and minimize operational costs. It explores the influence of various machining, environmental, and economic parameters on manufacturing outcomes, utilizing graph theory and meta-heuristic algorithms, such as Taguchi and genetic algorithms, for optimization. Additionally, it presents experimental results and analyses for tool life and production rates, emphasizing the importance of cutting quality and other factors in sustainable manufacturing practices.

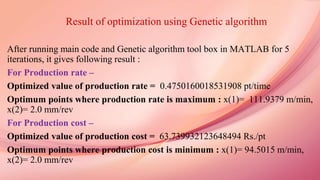

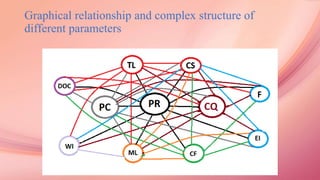

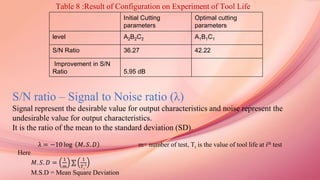

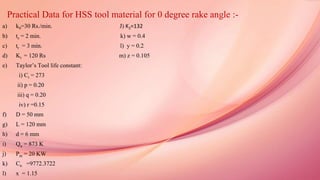

![Finding of most Influential parameters

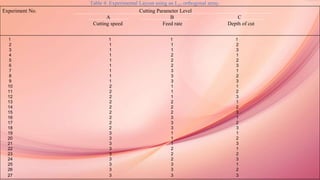

Method :- Local Centrality Method

local centrality measure as a tradeoff between low-relevant degree centrality and

other time-consuming measures. It is a part of graph theory.

It considers nearest neighbors only. The local centrality CL(v) of node v is

defined as–

𝑄 𝑢 = 𝑤∈Γ𝑢 𝑁(𝑤) …eq.(1)

𝐶 𝐿 𝑣 = 𝑢∈𝜇(𝑣) 𝑄(𝑢) …eq.(2)

[where Γ (u) and µ(v) is the set of the nearest neighbors of node u and v

respectively . N(w) is the number of the nearest neighbor of node w.]](https://image.slidesharecdn.com/finalsubmissionofmajorproject-160525083216/85/Sustainable-Manufacturing-Optimization-of-single-pass-Turning-machining-operation-using-Meta-heuristic-algorithm-9-320.jpg)

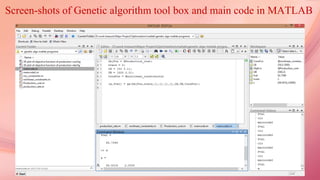

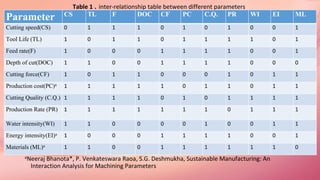

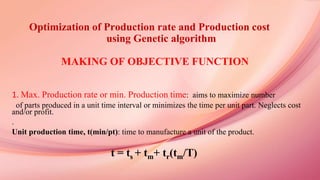

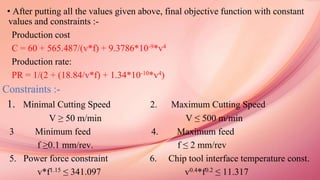

![• Unit production cost, u(Rs/pt): cost to manufacture a unit of the

product.

c = c1+ c3+ c4= kots+ kotm + [kt + kotr] (tm/T).

Where,

c1= capacity utilization cost (Rs/pt); includes machine cost, labor cost,

overhead etc.

ko= machine utilization rate (Rs/min)

c3= machining cost (associated with actual machining time); includes

cost of electricity, cutting fluids etc.

km= machining overhead (Rs/min).

c4= tool utilization cost; includes cost of cutting tool, tool re sharpening,

etc.

kt= cost per cutting edge (Rs/edge).](https://image.slidesharecdn.com/finalsubmissionofmajorproject-160525083216/85/Sustainable-Manufacturing-Optimization-of-single-pass-Turning-machining-operation-using-Meta-heuristic-algorithm-23-320.jpg)

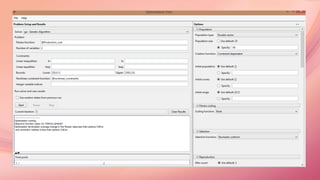

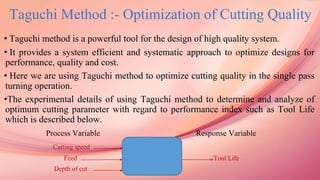

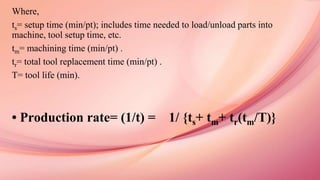

![Objective function with constraints

1. 𝑐 = 𝑐1 + 𝑐2 ∗ 𝑣

− 1 ∗ 𝑓

− 1 + π𝐷𝐿 ∗ 𝑑

𝑟

𝑝

∗ 𝑣

1

−

𝑃

𝑝

∗

𝑓

𝑞

−

𝑝

𝑝

1000∗𝑐𝑡

1

𝑝

Where, C1 = K0*ts

C2 = π*D*L*K0/1000

2. 𝑃𝑅 = 1/{𝑡𝑠 +

𝜋𝐷𝐿

1000∗𝑣∗𝑓

+ 𝑡𝑟[(𝜋𝐷𝐿 ∗ 𝑣

1

−

𝑝

𝑝

∗ 𝑓

𝑞

−

𝑝

𝑝

∗ 𝑑

𝑟

𝑝

]/ 1000 ∗ 𝑐𝑡

1

𝑝

Following to:-

1. vmin ≤ v ≤ vmax 2. fmin ≤ f ≤ fmax

3. Pm ≥ Cn*v*d*fx 4. Qu ≥ k2*vw*fy*dz](https://image.slidesharecdn.com/finalsubmissionofmajorproject-160525083216/85/Sustainable-Manufacturing-Optimization-of-single-pass-Turning-machining-operation-using-Meta-heuristic-algorithm-25-320.jpg)

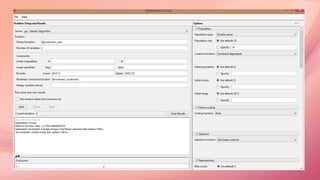

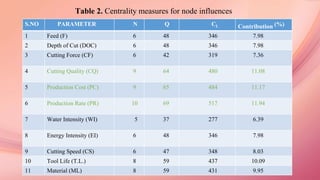

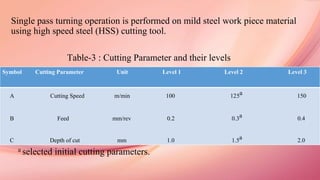

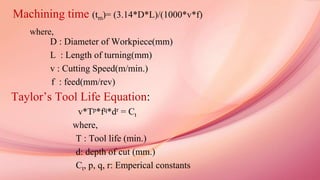

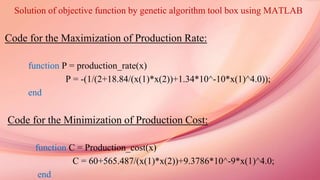

![Code for the Inequality Constraints:

function [T, ceq] = nonlinear_constraints(x)

T = [x(1)*x(2)^1.15-341.097;

x(1)^0.4*x(2)^0.2-11.317];

ceq = [];

end

[The above code will be applied on both the basic optimization function]

Main code to find Optimum points for Production rate and Production cost

ObjFcn = @production_rate/@production_cost;

nvars = 2;

LB = [50,0.1];

UB = [500,2.0];

ConsFcn = @nonlinear_constraints

[x, fval] = ga(ObjFcn, nvars, [], [], [], [], LB, UB, ConsFcn);](https://image.slidesharecdn.com/finalsubmissionofmajorproject-160525083216/85/Sustainable-Manufacturing-Optimization-of-single-pass-Turning-machining-operation-using-Meta-heuristic-algorithm-29-320.jpg)