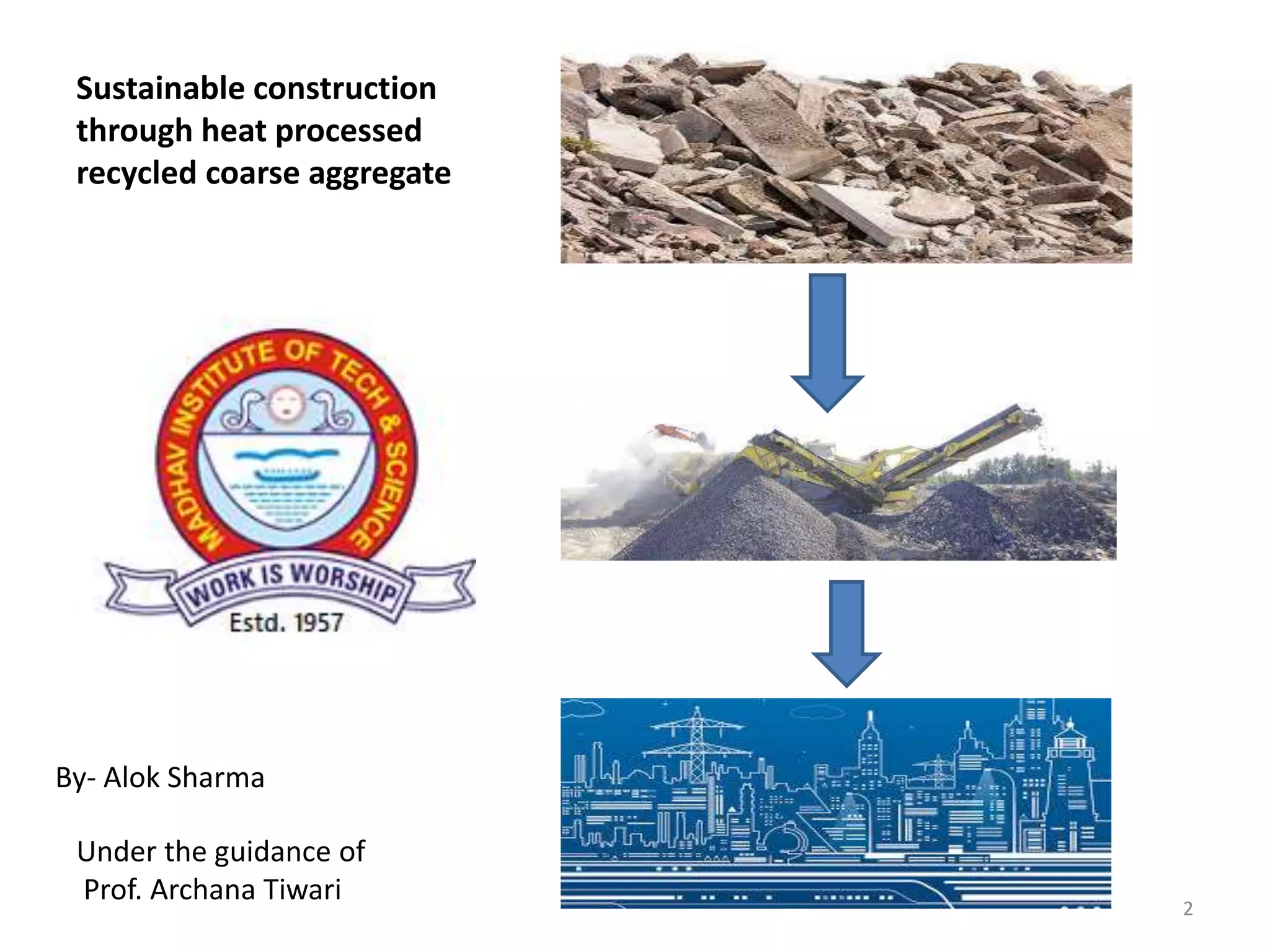

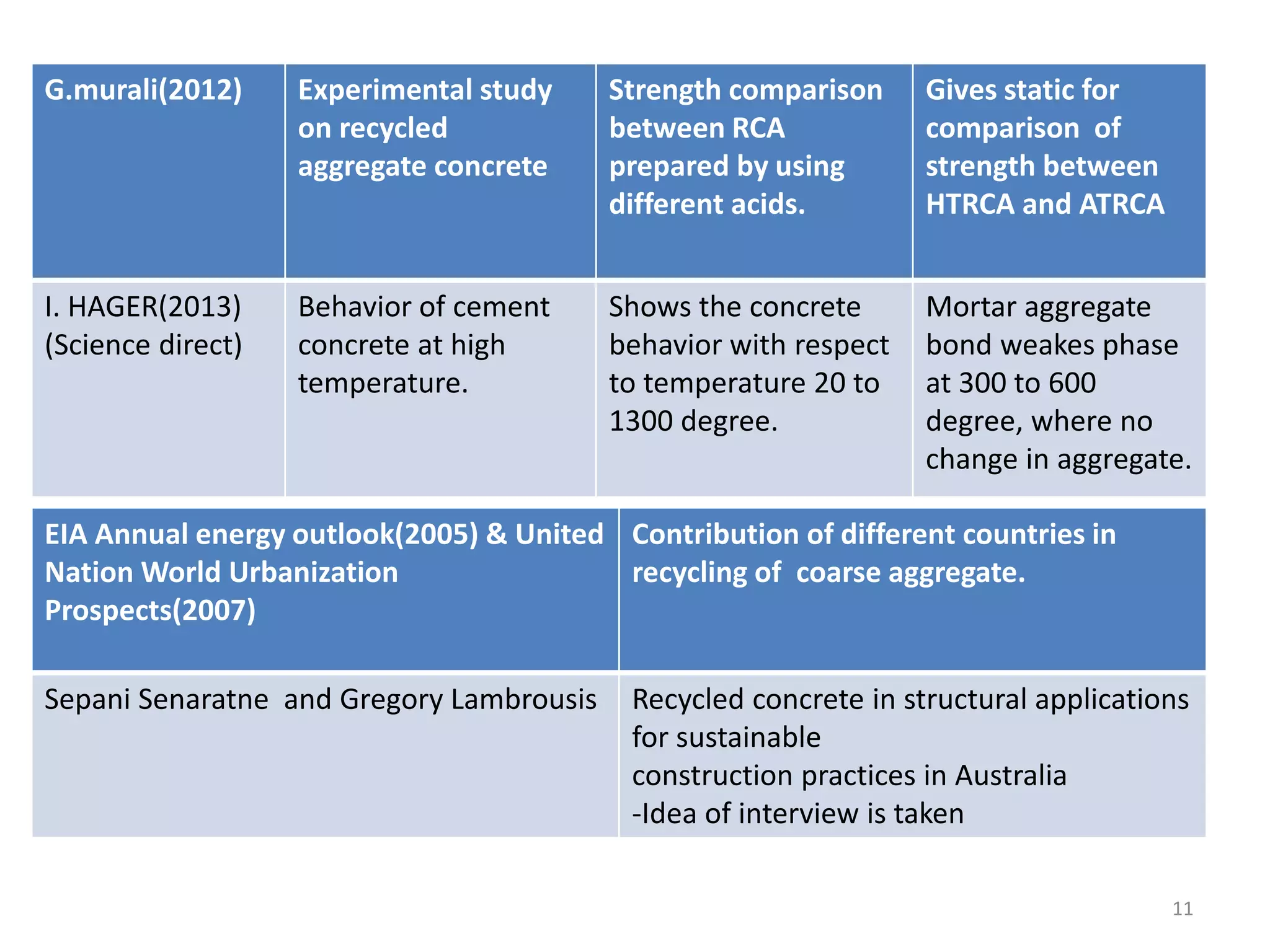

The document explores sustainable construction through the use of heat processed recycled coarse aggregate (RCA) to reduce solid waste and conserve natural resources. It outlines the objectives of understanding the role of RCA in construction, its mechanical properties, and the potential benefits and challenges of its adoption. Various methodologies, including qualitative interviews and numerical analysis, are presented to assess the viability of RCA compared to traditional aggregates.

![Reference use this study

• [01]Bentz,DP;Peltz,MA;Duran-Herrera,A;Valdez,P; and Jurarez,CA; "Thermal properties of high-

volume fly ash mortars and concretes",Journal of Building Physics,2011,v.34(3),pp. 263–275.

• [02]Bui,Ngoc Kien; Satomi, Tomaki; and Takahashi,Hiroshi;"Effect of mineral admixtures on

properties of recycle aggregate concrete at high temprature" Construction and Building material

V.184,2018,pp.361-373.

• [03]Chung,Shan-Shan; and Lo, Carlos W.H.;" Evaluating sustainability in waste management: the

case of construction and demolition, chemical and clinical wastes in Hong Kong", Resources,

Conservation and Recycling,v.37,2003,p.p.119-145.

• [04] Guideline of environmental Management of Construction & demolition waste march 2017.

• [05] IS 10262:2019, design concrete mix

• [06] IS 12269:2013, OPC 53.

• [07] IS 269:2015, properties of cement.

• [08] IS 2386, part 1-8, aggregate test.

• [09] IS 383:1970, coarse aggregate.

• [10] IS 456:2000, properties of concrete.

• [11] IS 516:1959 part-4 , strength test of concrete.

55](https://image.slidesharecdn.com/sustainableconstructiontroughheatprocessedrecycledcoarseaggregate-210309113320/75/Sustainable-construction-trough-heat-processed-recycled-coarse-aggregate-55-2048.jpg)

![• [12] Kou,S.C. and Poon,C.S.; "Enhancing the durability properties of concrete prepared with course

recycled aggregate", Construction and Building material,V.35,2012,pp.69-76.

• [13]Marinkovic,S.;Radonjanin,V.;Malesev,M.; and Ignjatovic,I.; "Comparative environmental

assessment of natural and recycled aggregate concrete",Waste Management,V.30,2010,pp.2255-

2264.

• [14]Murali,G.;Vardhan,C.M.Vivek;Rajan,Gabriela;Janani,G.J.;Janan, N.Shifu; and Ramyashri,R;

"Experimental study on recycled aggregate concrete", International Journal of Engineering Research

and Application(IJERA),V.2,march-april 2012,pp.407-410.

• [15] Murty,D.Sree Ramachandra; Suresh,D.;Dinkar,P.; and Lava kumar,S.K.V.S.T.; "High Volume Fly

Ash Cement, Recycle Course Aggregate and Stone Crusher Dust Combined For Sustainable

Structural Concrete"; ICI journal, January-march 2019.

•

• [16]Poon, C. S.; Shui, Z. H.; and Lam, L.; " Effect of microstructure of ITZ on compressive strength of

concrete prepared with recycled aggregates." 2004(18), 461-468.

• [17]Poon, C. S.; Shui, Z. H.; Lam, L.; Fok, H.; & Kou, S. C.; " Influence of moisture states of natural

and recycled aggregates on the slump and compressive strength of concrete".2004(34), 31-36.

• [18] Pour-Ghaz, M.; Castro, J.; Kladivko, E.; and Weiss, J.;" A Short Report on the Use of Pressure

Plates to Measure Desorption" West Lafayette, Indiana: Purdue University2011(43),pp..

• [19] Poulikakos, L.D.; Papadaskalopoulou,C.; Hofko,B.; Gschösser,F.; Cannone Falchetto,A.;

Bueno,M.; Arraigada, M; Sousa,J.; Ruiz,R.; Petit, J.; Loizidou,M.; and Partl,M.N." Harvesting the

unexplored potential of European waste materials for road construction", Resources, Conservation

and Recycling,V.116,2017,p.p.32-44.

• [20] Radojanin,Vlastimir;Malesev,Mirjana;Marinkovic,Snezana; and Malty,Ali Emhemd saed Al;

"Green recycle aggregate concrete", Construction and Building Material V.47,2013,pp.1503-1511.

56](https://image.slidesharecdn.com/sustainableconstructiontroughheatprocessedrecycledcoarseaggregate-210309113320/75/Sustainable-construction-trough-heat-processed-recycled-coarse-aggregate-56-2048.jpg)

![• [21] Revathi,Purushotham and Selvi,R.Senthamil; "Characterisation of Recycle Concrete Aggregate

Based on Attached Mortar Content for Structural Concrete application" ,ICI journal, January-march

2019.

• [22]Senaratne,Sepani; Lambrousis, Gregory; Mirza,Olivia; Tam,Vivan W.Y. and Kang,Won-Hee

"Recycled concrete in structural applications for sustainable construction practices in Australia",

Science direct journal,V.180, 2017,p.p.751-758.

• [23] Sunil,Kumar; Stephen, R. Smith; Geoff,Fowler; Costas,Velis; S., Jyoti Kumar; Shashi, Arya Rena;

Rakesh,Kumar; and Christopher,Cheeseman; "Challenges and opportunities associated with waste

management in India", Journal of Royal society open science, February 2017.

• [24]Sustainable development union website of UN(2020) and Source-website of Europian

Demolition Association and Website of EPA, USA(2020).

• [25] Tiwari,Archana; and Dwivedi,Prakash;" Characteristics of Concrete Made with Partial

Replacement of Natural Aggregates by Aggregate Recovered from Waste Concrete", International

Journal of Engineering Research & Technology (IJERT),9th sept.2014, V.3, ISSN: 2278-0181.

• [26]Tosic,Nikola; Marinkovic,Snezana; Dosic,Tina; and Stanic,Milas;" Multicriteria optimization of

natural and recycled aggregate concrete for structural use",Journal of Cleaner

Production,2014,p.p.1-11.

• [27]Wagih,Ashraf M.; El-Karmoty,Hossam Z.;Ebid,Magda; and Okba Samir H.;"Recycled construction

and demolition concrete waste as aggregate for structural concrete", Journal Housing and Building

National Research center,V.9,2013,pp.193-200.

• [28]Yadhu,G. and S Aishwarya devi;"An Innovative Study on Reuse of Demolished Concrete

Waste"Journal of Civil and Environmental engineering,27 Aug.2015,V.5,pp.272-291.

• [29]Yonis,Adel; Ebead,Usama; and Judd,Simon;" Life cycle cost analysis of structural concrete using

seawater, recycled concrete aggregate, and GFRP reinforcement", Construction and Building

Materials,V.175,2018,p.p.152-160.

57](https://image.slidesharecdn.com/sustainableconstructiontroughheatprocessedrecycledcoarseaggregate-210309113320/75/Sustainable-construction-trough-heat-processed-recycled-coarse-aggregate-57-2048.jpg)