SURP_Poster_2016

•

0 likes•23 views

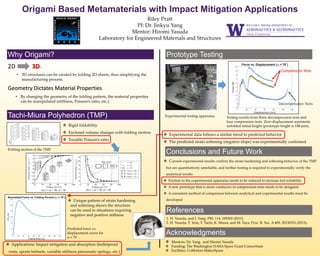

Origami-based metamaterials can be used for impact mitigation applications by manipulating material properties through geometric folding patterns. The Tachi-Miura Polyhedron (TMP) exhibits rigid foldability, tunable enclosed volume, and unique strain hardening and softening behavior, making it suitable for situations requiring negative and positive stiffness. Experimental compression and decompression tests on a TMP prototype confirmed the predicted strain behavior but were quantitatively unreliable due to friction. Further testing is needed to verify analytical models, improve test reliability, and develop consistent comparison methods between experiment and theory.

Report

Share

Report

Share

Download to read offline

Recommended

Tensile testing ppt

This document discusses tensile testing and universal testing machines. It defines tensile testing as applying opposing tensile forces to a test specimen to measure the specimen's properties. A universal testing machine typically uses a hydraulic cylinder to apply the force. The document lists several material properties that can be determined from tensile tests, including strength, ductility, elasticity, and stiffness. It provides diagrams illustrating how properties like tensile strength, modulus of elasticity, and breaking stress are calculated from the stress-strain graph generated during tensile testing. Finally, it gives some examples of industries that use tensile testing, like aerospace and textiles, and notes benefits like determining batch quality and aiding design.

Testing the Tensile Properties of Rigid and Semi-rigid Plastics (ASTM D638 an...

Testing the Tensile Properties of Rigid and Semi-rigid Plastics (ASTM D638 an...Shimadzu Scientific Instruments

Tensile testing is one method routinely used to determine the mechanical properties of plastics. This piece presents an example of measuring the mechanical properties of acrylonitrile butadiene styrene (ABS), Polyoxymethylene (POM), Polyethylene terephthalate (PET) and polystyrene (PS) 4 tension test

This experiment tested the tensile properties of steel, aluminum, and two polymeric materials. Specimens of each material were pulled apart in a tensile testing machine at a constant strain rate to measure properties like yield strength, tensile strength, and elongation. The engineering stress-strain and true stress-strain curves were plotted and compared for each material. Values for properties like Young's modulus, yield stress, and tensile strength were determined from the curves and compared to literature values. Sources of experimental error were also discussed.

Work Experience

This will give you a brief idea of my research work and my work experience and the projects I have worked on. With a keen eye on the details of each.

tensile strength

Tensile testing is a fundamental materials science method where a sample is pulled apart under controlled tension until failure. It determines how materials react under tensile stress and yields data on material properties like elastic limit and failure point. This allows designers to predict how materials will perform in applications. Tensile testing provides data on material integrity and quality, helping manufacturers ensure products are fit for purpose and meet standards. The basic approach involves applying a tensile load to a specimen and measuring its elongation until fracture to determine properties like tensile strength. Factors that influence tensile strength include additives, temperature, geometry, orientation, surface condition, loading rate and environment.

Tensile test

Tensile test research and accurate data for academics and professional engineers. Engineers use tensile tests to solve most fracture problems.

Tensile test

Tensile testing subjects a material sample to controlled tension until failure to determine properties like ultimate tensile strength and elongation. The test uses a universal testing machine to apply tension to a standardized tensile specimen, measuring properties like modulus of elasticity, yield stress, and fracture stress. The test procedure involves securing the specimen in the machine and applying tension until failure while recording the stress-strain curve.

Modeling plastics in ANSYS

The document discusses modeling the behavior of thermoplastics in ANSYS. It describes the stress-strain behavior of thermoplastics under different loading conditions such as uniaxial tension, loading-unloading, creep, and relaxation. It also lists several material models in ANSYS that can be used to model different thermoplastic behaviors, such as elastic-plastic, hyperelastic, viscoelastic, and viscoplastic models. It provides guidance on choosing the appropriate material model based on the available experimental data, operating loading conditions, and simulation objectives.

Recommended

Tensile testing ppt

This document discusses tensile testing and universal testing machines. It defines tensile testing as applying opposing tensile forces to a test specimen to measure the specimen's properties. A universal testing machine typically uses a hydraulic cylinder to apply the force. The document lists several material properties that can be determined from tensile tests, including strength, ductility, elasticity, and stiffness. It provides diagrams illustrating how properties like tensile strength, modulus of elasticity, and breaking stress are calculated from the stress-strain graph generated during tensile testing. Finally, it gives some examples of industries that use tensile testing, like aerospace and textiles, and notes benefits like determining batch quality and aiding design.

Testing the Tensile Properties of Rigid and Semi-rigid Plastics (ASTM D638 an...

Testing the Tensile Properties of Rigid and Semi-rigid Plastics (ASTM D638 an...Shimadzu Scientific Instruments

Tensile testing is one method routinely used to determine the mechanical properties of plastics. This piece presents an example of measuring the mechanical properties of acrylonitrile butadiene styrene (ABS), Polyoxymethylene (POM), Polyethylene terephthalate (PET) and polystyrene (PS) 4 tension test

This experiment tested the tensile properties of steel, aluminum, and two polymeric materials. Specimens of each material were pulled apart in a tensile testing machine at a constant strain rate to measure properties like yield strength, tensile strength, and elongation. The engineering stress-strain and true stress-strain curves were plotted and compared for each material. Values for properties like Young's modulus, yield stress, and tensile strength were determined from the curves and compared to literature values. Sources of experimental error were also discussed.

Work Experience

This will give you a brief idea of my research work and my work experience and the projects I have worked on. With a keen eye on the details of each.

tensile strength

Tensile testing is a fundamental materials science method where a sample is pulled apart under controlled tension until failure. It determines how materials react under tensile stress and yields data on material properties like elastic limit and failure point. This allows designers to predict how materials will perform in applications. Tensile testing provides data on material integrity and quality, helping manufacturers ensure products are fit for purpose and meet standards. The basic approach involves applying a tensile load to a specimen and measuring its elongation until fracture to determine properties like tensile strength. Factors that influence tensile strength include additives, temperature, geometry, orientation, surface condition, loading rate and environment.

Tensile test

Tensile test research and accurate data for academics and professional engineers. Engineers use tensile tests to solve most fracture problems.

Tensile test

Tensile testing subjects a material sample to controlled tension until failure to determine properties like ultimate tensile strength and elongation. The test uses a universal testing machine to apply tension to a standardized tensile specimen, measuring properties like modulus of elasticity, yield stress, and fracture stress. The test procedure involves securing the specimen in the machine and applying tension until failure while recording the stress-strain curve.

Modeling plastics in ANSYS

The document discusses modeling the behavior of thermoplastics in ANSYS. It describes the stress-strain behavior of thermoplastics under different loading conditions such as uniaxial tension, loading-unloading, creep, and relaxation. It also lists several material models in ANSYS that can be used to model different thermoplastic behaviors, such as elastic-plastic, hyperelastic, viscoelastic, and viscoplastic models. It provides guidance on choosing the appropriate material model based on the available experimental data, operating loading conditions, and simulation objectives.

Lab report engineering materials lab - tensile test

This is my Lab Report of Tensile Test when I was conducting engineering material lab in Sampoerna University. Feel free to download for a reference.

I know it is not a good report, but I hope this share might help you to find something you need.

Thank you.

IRJET- Investigation and Analysis of Multiple Cracks in Cantilever Beam by us...

The document investigates the free vibration analysis of uniform and stepped cantilever beams with single and multiple cracks using finite element modeling. An experimental study is conducted to validate the numerical results. The presence of cracks reduces the local stiffness matrix and alters the natural frequencies of the system. Results show that as crack depth increases, frequency reduction also increases for both uniform and stepped beams. Natural frequencies are more influenced by crack location than depth. Cracks near fixed ends have a greater effect on the first natural frequency mode compared to cracks near free ends.

Ti nano

Nano Indentation Effects on Ti6Al4VELI During Excimer Laser Irradiation

the effect of laser irradiation on the properties of Ti6Al4VELI

Ansys Workbench-Chapter14

This chapter discusses nonlinear materials and their behavior. It covers the basics of linear and nonlinear materials, elasticity, plasticity, hyperelasticity, and the models available in Workbench. It then provides two step-by-step examples: a Belleville washer made of steel and subjected to compression and release, and a rubber seal between two steel plates, with the top plate displaced downward. Force-displacement curves are generated for each example and residual stresses examined.

Experimental Investigation and Analysis of Extrusion of Lead from Round Secti...

Abstract : An experimental investigation has been done on the changes of die angle, area reduction in dies,

loading rate on the final extruded products, extrusion pressures of lead of circular cross sections of different

length. The proposed method is successfully adapted to the extrusion of the equilateral triangular section from

round billet through converging dies of different area reductions. Computation of extrusion pressure at various

area reductions and finite element analysis of different parameters (stress, strain, velocity) both in dry and wet

condition.

Keywords - Converging dies, Extrusion of the equilateral triangular section, Extrusion Pressure

ScilabTEC 2015 - TUM

"Material testing and hyperelastic material model curve fitting for Ogden, Polynomial and Yeoh models"

By Michael Rackl, Technische Universität München for ScilabTEC 2015

Hyperelastic material models in finite element analysis of polymers

This paper describes the Hyperelastic material models and strain energy functions used in the finite element analysis (FEA) of polymers. Material characterization testing

Determination Of Geometric Stress Intensity Factor For A Photoelastic Compac...

Experimental and analytical studies with finite elements was done on a polycarbonate transparent material as a forerunner to a similar study on transparent glass -epoxy composites

Probabilistic Design of Hollow Circular Composite Structure by using Finite E...

This document summarizes a study that uses finite element analysis to analyze the bending stress of a hollow circular composite beam under static loading conditions while accounting for uncertainty in design variables. A probabilistic design system is used to simulate the effects of varying the beam's length, radius, material properties, ply angles, thickness, and applied load on the bending stress. The results identify that variation in load, radius, modulus, ply thickness, and angles have the most significant effect on bending stress. The analysis finds the bending stress can range from 104 to 392 MPa with a 90% probability of being below 250 MPa. Improving the robustness of the design may require addressing variables with the highest sensitivity on bending stress.

TENSILE TEST REPORT

In the material testing laboratory, Tensile test was done on a mild steel specimen as figure 4 to identify the young’s modulus, ultimate tensile strength, yield strength and percentage elongation. The results were as table 1

Lecture 3

This document discusses stress-strain graphs of various materials and their mechanical properties. It defines ductile and brittle materials based on their stress-strain curves and percentage elongation. Figures and explanations are provided on tensile testing machines, typical stress-strain diagrams for different materials like steel and wire, Poisson's ratio definition and calculations.

Multi Response Optimization of Friction Stir Lap Welding Process Parameters U...

This document summarizes a study that optimized friction stir lap welding process parameters using a multi-criteria decision making approach. Experiments were conducted using different combinations of tool rotational speed, welding speed, and tool tilt angle. The responses of hardness, shear strength, elongation percentage, and peak load were measured. These responses were optimized using Deng's similarity-based method to determine the optimal parameter values. The method calculated normalized values, assigned weights to each response, and determined positive and negative ideal solutions. It was found that the optimum parameter values were a tool rotational speed of 710 rpm, welding speed of 1.5 mm/min, and tool tilt angle of 1 degree.

IRJET-Experimental Study on Spring Back Phenomenon in Sheet Metal V- Die Bending

This document presents an experimental study on the spring back phenomenon in sheet metal V-die bending. The study investigates how factors like angle, sheet thickness, and varying width cross-section affect the amount of spring back that occurs in CRC-D steel sheets. Experiments were conducted using a design of experiments approach based on response surface methodology. 20 bending experiments were performed according to the experimental design matrix. The results show that spring back decreases with increasing angle and first increases then decreases with increasing thickness. Spring back also increases linearly with increasing width. A regression model was developed to predict spring back based on the experimental results.

Universal testing machines

The document discusses a presentation on a universal testing machine. It describes how the machine is used to apply tensile, compressive, and shear forces to test materials and measure their properties. It explains that the machine uses load cells, crossheads, and columns to grip specimens and apply and measure forces. The document outlines the working principle of the machine and procedures for tensile and compression tests.

643051

This study compares experimental and finite element analysis results for stress analysis. Strain gauges were placed on test materials (a beam and contacting blocks) at locations corresponding to finite element mesh nodes. Testing involved applying loads and measuring strain. Results showed good agreement between experimental and numerical analyses for the linear beam problem. For the nonlinear contacting blocks problem, close placement of strain gauges was important due to high stress gradients at contact points. Small gauge placement errors could cause up to 10% difference in strain measurements. The approach demonstrated that matching strain gauge locations to finite element meshes facilitated accurate validation of numerical models.

Performance Optimization of Tie rod using FEA

Structural performance of any mechanical component is measured basically in terms of its natural frequency, deformation, stiffness, maximum stress level, fatigue life etc. In case of vehicle suspension system; however tie rod is mainly under compressive and fluctuating forces encounter from steering and bumping of vehicle. When steering acts to turn the vehicle, tie rod comes under compressive load. And when vehicle running on rough road condition, fluctuating forces.

3

1) The document describes a finite element analysis of the superplastic blow-forming of Ti-6Al-4V titanium alloy sheet into a closed ellip-cylindrical die.

2) The simulations investigate the effects of shear friction factor, die entry radius, die height, and die short-axis length on thickness distribution, stress, strain, and damage within the formed product.

3) The results confirm the suitability of using the DEFORMTM 3D finite element software to model superplastic blow-forming of Ti-6Al-4V titanium alloy.

stress \strain

This document contains a summary of key concepts related to stress and strain in materials:

1. It defines stress as the force per unit area on a material, and strain as the ratio of deformation to original dimension when a material is subjected to external forces.

2. Specific types of strain are described, including direct strain as deformation per unit length and shear strain measured as the change in angle.

3. The document outlines that stress-strain diagrams can be used to illustrate the behavior of materials when forces are applied, with ductile materials exhibiting different stress-strain curves than brittle materials.

Analysis of stiffened isotropic and composite plate

This document summarizes a research paper that analyzed both isotropic and composite plates with and without stiffeners using finite element modeling. It presented the following key points:

1. Finite element models of isotropic and composite plates were created using shell and solid elements in ANSYS to analyze the effect of stiffeners on plate deformation and stress.

2. Parametric studies were performed by varying the length, thickness, and height of stiffeners to minimize plate deformation without increasing material volume.

3. Results showed that stiffened plates had significantly less deformation than bare plates for the same material volume. Deformation generally decreased with increasing stiffener size.

Investigation of Extrusion of Lead experimentally from Round section through ...

ABSTRACT :The changes of die angle, area reduction in dies, loading rate on the final extruded products, extrusion pressures of lead of circular cross sections has been investigated experimentally. The proposed method is successfully adapted to the forward extrusion of the equilateral triangular section from round billet through converging dies of different area reductions. Computation of extrusion pressure at various area reductions and calculations of different parameters (stress, strain etc.) in wet condition.

Keywords - Extrusion of Triangular section, Converging Dies at different area reductions, Friction Factor, Extrusion Pressure

A 12.pptx

This document describes a project to fabricate and experimentally test a torsion test rig. The objectives are to design and fabricate an apparatus to test the torsional strength of metal workpieces and verify the modulus of rigidity. The methodology involves conceptual design, material selection, manufacturing, and experimental testing from July 2019 to February 2020. Calculations are provided to determine shear stress and modulus of rigidity from torque and angular displacement measurements during testing.

0 exp no.4 bending test experiment

Muhammed Fuad Rashid

Petroleum Engineering Department at Koya University

Mechanics of material Laboratory

2020

More Related Content

What's hot

Lab report engineering materials lab - tensile test

This is my Lab Report of Tensile Test when I was conducting engineering material lab in Sampoerna University. Feel free to download for a reference.

I know it is not a good report, but I hope this share might help you to find something you need.

Thank you.

IRJET- Investigation and Analysis of Multiple Cracks in Cantilever Beam by us...

The document investigates the free vibration analysis of uniform and stepped cantilever beams with single and multiple cracks using finite element modeling. An experimental study is conducted to validate the numerical results. The presence of cracks reduces the local stiffness matrix and alters the natural frequencies of the system. Results show that as crack depth increases, frequency reduction also increases for both uniform and stepped beams. Natural frequencies are more influenced by crack location than depth. Cracks near fixed ends have a greater effect on the first natural frequency mode compared to cracks near free ends.

Ti nano

Nano Indentation Effects on Ti6Al4VELI During Excimer Laser Irradiation

the effect of laser irradiation on the properties of Ti6Al4VELI

Ansys Workbench-Chapter14

This chapter discusses nonlinear materials and their behavior. It covers the basics of linear and nonlinear materials, elasticity, plasticity, hyperelasticity, and the models available in Workbench. It then provides two step-by-step examples: a Belleville washer made of steel and subjected to compression and release, and a rubber seal between two steel plates, with the top plate displaced downward. Force-displacement curves are generated for each example and residual stresses examined.

Experimental Investigation and Analysis of Extrusion of Lead from Round Secti...

Abstract : An experimental investigation has been done on the changes of die angle, area reduction in dies,

loading rate on the final extruded products, extrusion pressures of lead of circular cross sections of different

length. The proposed method is successfully adapted to the extrusion of the equilateral triangular section from

round billet through converging dies of different area reductions. Computation of extrusion pressure at various

area reductions and finite element analysis of different parameters (stress, strain, velocity) both in dry and wet

condition.

Keywords - Converging dies, Extrusion of the equilateral triangular section, Extrusion Pressure

ScilabTEC 2015 - TUM

"Material testing and hyperelastic material model curve fitting for Ogden, Polynomial and Yeoh models"

By Michael Rackl, Technische Universität München for ScilabTEC 2015

Hyperelastic material models in finite element analysis of polymers

This paper describes the Hyperelastic material models and strain energy functions used in the finite element analysis (FEA) of polymers. Material characterization testing

Determination Of Geometric Stress Intensity Factor For A Photoelastic Compac...

Experimental and analytical studies with finite elements was done on a polycarbonate transparent material as a forerunner to a similar study on transparent glass -epoxy composites

Probabilistic Design of Hollow Circular Composite Structure by using Finite E...

This document summarizes a study that uses finite element analysis to analyze the bending stress of a hollow circular composite beam under static loading conditions while accounting for uncertainty in design variables. A probabilistic design system is used to simulate the effects of varying the beam's length, radius, material properties, ply angles, thickness, and applied load on the bending stress. The results identify that variation in load, radius, modulus, ply thickness, and angles have the most significant effect on bending stress. The analysis finds the bending stress can range from 104 to 392 MPa with a 90% probability of being below 250 MPa. Improving the robustness of the design may require addressing variables with the highest sensitivity on bending stress.

TENSILE TEST REPORT

In the material testing laboratory, Tensile test was done on a mild steel specimen as figure 4 to identify the young’s modulus, ultimate tensile strength, yield strength and percentage elongation. The results were as table 1

Lecture 3

This document discusses stress-strain graphs of various materials and their mechanical properties. It defines ductile and brittle materials based on their stress-strain curves and percentage elongation. Figures and explanations are provided on tensile testing machines, typical stress-strain diagrams for different materials like steel and wire, Poisson's ratio definition and calculations.

Multi Response Optimization of Friction Stir Lap Welding Process Parameters U...

This document summarizes a study that optimized friction stir lap welding process parameters using a multi-criteria decision making approach. Experiments were conducted using different combinations of tool rotational speed, welding speed, and tool tilt angle. The responses of hardness, shear strength, elongation percentage, and peak load were measured. These responses were optimized using Deng's similarity-based method to determine the optimal parameter values. The method calculated normalized values, assigned weights to each response, and determined positive and negative ideal solutions. It was found that the optimum parameter values were a tool rotational speed of 710 rpm, welding speed of 1.5 mm/min, and tool tilt angle of 1 degree.

IRJET-Experimental Study on Spring Back Phenomenon in Sheet Metal V- Die Bending

This document presents an experimental study on the spring back phenomenon in sheet metal V-die bending. The study investigates how factors like angle, sheet thickness, and varying width cross-section affect the amount of spring back that occurs in CRC-D steel sheets. Experiments were conducted using a design of experiments approach based on response surface methodology. 20 bending experiments were performed according to the experimental design matrix. The results show that spring back decreases with increasing angle and first increases then decreases with increasing thickness. Spring back also increases linearly with increasing width. A regression model was developed to predict spring back based on the experimental results.

Universal testing machines

The document discusses a presentation on a universal testing machine. It describes how the machine is used to apply tensile, compressive, and shear forces to test materials and measure their properties. It explains that the machine uses load cells, crossheads, and columns to grip specimens and apply and measure forces. The document outlines the working principle of the machine and procedures for tensile and compression tests.

643051

This study compares experimental and finite element analysis results for stress analysis. Strain gauges were placed on test materials (a beam and contacting blocks) at locations corresponding to finite element mesh nodes. Testing involved applying loads and measuring strain. Results showed good agreement between experimental and numerical analyses for the linear beam problem. For the nonlinear contacting blocks problem, close placement of strain gauges was important due to high stress gradients at contact points. Small gauge placement errors could cause up to 10% difference in strain measurements. The approach demonstrated that matching strain gauge locations to finite element meshes facilitated accurate validation of numerical models.

Performance Optimization of Tie rod using FEA

Structural performance of any mechanical component is measured basically in terms of its natural frequency, deformation, stiffness, maximum stress level, fatigue life etc. In case of vehicle suspension system; however tie rod is mainly under compressive and fluctuating forces encounter from steering and bumping of vehicle. When steering acts to turn the vehicle, tie rod comes under compressive load. And when vehicle running on rough road condition, fluctuating forces.

3

1) The document describes a finite element analysis of the superplastic blow-forming of Ti-6Al-4V titanium alloy sheet into a closed ellip-cylindrical die.

2) The simulations investigate the effects of shear friction factor, die entry radius, die height, and die short-axis length on thickness distribution, stress, strain, and damage within the formed product.

3) The results confirm the suitability of using the DEFORMTM 3D finite element software to model superplastic blow-forming of Ti-6Al-4V titanium alloy.

stress \strain

This document contains a summary of key concepts related to stress and strain in materials:

1. It defines stress as the force per unit area on a material, and strain as the ratio of deformation to original dimension when a material is subjected to external forces.

2. Specific types of strain are described, including direct strain as deformation per unit length and shear strain measured as the change in angle.

3. The document outlines that stress-strain diagrams can be used to illustrate the behavior of materials when forces are applied, with ductile materials exhibiting different stress-strain curves than brittle materials.

Analysis of stiffened isotropic and composite plate

This document summarizes a research paper that analyzed both isotropic and composite plates with and without stiffeners using finite element modeling. It presented the following key points:

1. Finite element models of isotropic and composite plates were created using shell and solid elements in ANSYS to analyze the effect of stiffeners on plate deformation and stress.

2. Parametric studies were performed by varying the length, thickness, and height of stiffeners to minimize plate deformation without increasing material volume.

3. Results showed that stiffened plates had significantly less deformation than bare plates for the same material volume. Deformation generally decreased with increasing stiffener size.

Investigation of Extrusion of Lead experimentally from Round section through ...

ABSTRACT :The changes of die angle, area reduction in dies, loading rate on the final extruded products, extrusion pressures of lead of circular cross sections has been investigated experimentally. The proposed method is successfully adapted to the forward extrusion of the equilateral triangular section from round billet through converging dies of different area reductions. Computation of extrusion pressure at various area reductions and calculations of different parameters (stress, strain etc.) in wet condition.

Keywords - Extrusion of Triangular section, Converging Dies at different area reductions, Friction Factor, Extrusion Pressure

What's hot (20)

Lab report engineering materials lab - tensile test

Lab report engineering materials lab - tensile test

IRJET- Investigation and Analysis of Multiple Cracks in Cantilever Beam by us...

IRJET- Investigation and Analysis of Multiple Cracks in Cantilever Beam by us...

Experimental Investigation and Analysis of Extrusion of Lead from Round Secti...

Experimental Investigation and Analysis of Extrusion of Lead from Round Secti...

Hyperelastic material models in finite element analysis of polymers

Hyperelastic material models in finite element analysis of polymers

Determination Of Geometric Stress Intensity Factor For A Photoelastic Compac...

Determination Of Geometric Stress Intensity Factor For A Photoelastic Compac...

Probabilistic Design of Hollow Circular Composite Structure by using Finite E...

Probabilistic Design of Hollow Circular Composite Structure by using Finite E...

Multi Response Optimization of Friction Stir Lap Welding Process Parameters U...

Multi Response Optimization of Friction Stir Lap Welding Process Parameters U...

IRJET-Experimental Study on Spring Back Phenomenon in Sheet Metal V- Die Bending

IRJET-Experimental Study on Spring Back Phenomenon in Sheet Metal V- Die Bending

Analysis of stiffened isotropic and composite plate

Analysis of stiffened isotropic and composite plate

Investigation of Extrusion of Lead experimentally from Round section through ...

Investigation of Extrusion of Lead experimentally from Round section through ...

Similar to SURP_Poster_2016

A 12.pptx

This document describes a project to fabricate and experimentally test a torsion test rig. The objectives are to design and fabricate an apparatus to test the torsional strength of metal workpieces and verify the modulus of rigidity. The methodology involves conceptual design, material selection, manufacturing, and experimental testing from July 2019 to February 2020. Calculations are provided to determine shear stress and modulus of rigidity from torque and angular displacement measurements during testing.

0 exp no.4 bending test experiment

Muhammed Fuad Rashid

Petroleum Engineering Department at Koya University

Mechanics of material Laboratory

2020

Experiment 4 - Testing of Materials in Tension Object .docx

Experiment 4 - Testing of Materials in Tension

Object: The object of this experiment is to measure the tensile properties of two polymeric

materials, steel and aluminum at a constant strain rate on the Tension testing machine.

Background: For structural applications of materials such as bridges, pressure vessels, ships,

and automobiles, the tensile properties of the metal material set the criteria for a safe design.

Polymeric materials are being used more and more in structural applications, particularly in

automobiles and pressure vessels. New applications emerge as designers become aware of

the differences in the properties of metals and polymers and take full advantage of them. The

analyses of structures using metals or plastics require that the data be available.

Stress-Strain: The tensile properties of a material are obtained by pulling a specimen of

known geometry apart at a fixed rate of straining until it breaks or stretches to the machines

limit. It is useful to define the load per unit area (stress) as a parameter rather than load to

avoid the confusion that would arise from the fact that the load and the change in length are

dependent on the cross-sectional area and original length of the specimen. The stress,

however, changes during the test for two reasons: the load increases and the cross-sectional

area decreases as the specimen gets longer.

Therefore, the stress can be calculated by two formulae which are distinguished as

engineering stress and true stress, respectively.

(1) = P/Ao= Engineering Stress (lbs/in

2 or psi)

P = load (lbs)

Ao= original cross-sectional area (in

2)

(2) T= P/Ai = True Stress

Ai = instantaneous cross-sectional area (in

2)

Likewise, the elongation is normalized per unit length of specimen and is called strain. The

strain may be based on the original length or the instantaneous length such that

(3) =(lf - lo)/ lo = l / lo = Engineering Strain, where

lf= final gage length (in)

lo= original gage length (in)

(4) T= ln ( li / lo ) = ln (1 +) = True Strain, where

li = instantaneous gage length (in)

ln = natural logarithm

For a small elongation the engineering strain is very close to the true strain when l=1.2 lo,

then = 0.2 and T= ln 1.2 = 0.182. The engineering stress is related to the true stress by

(5) T= (1 + )

The true stress would be 20% higher in the case above where the specimen is 20% longer

than the original length. As the relative elongation increases, the true strain will become

significantly less than the engineering strain while the true stress becomes much greater than

the engineering stress. When l= 4.0 lo then = 3.0 but the true strain =ln 4.0 = 1.39.

Therefore, the true strain is less than 1/2 of the engineering strain. The true stress (T) = (1+

3.0) = 4, or the true stress is 4 times the engineering stress.

Tensile Test Nom ...

exp no.2 compressive test

Muhammed Fuad Rashid

Petroleum Engineering Department at Koya University

Mechanics of material Laboratory

2020

honeycomb sandwich structure

This document summarizes the design and analysis of honeycomb structures. It discusses how honeycomb structures have desirable properties like high strength to weight ratio and corrosion resistance. It then reviews several studies on analyzing honeycomb structures under dynamic loading. The objective is to design and analyze honeycomb sandwich structure performance under dynamic blast loading. Numerical modeling is performed to model the honeycomb structure and validate the model against experimental data, showing good agreement. Results and discussions analyze the honeycomb structure's response to impact loading. In conclusion, the simulation model is found to accurately predict honeycomb structure behavior under dynamic loads.

FE Simulation Modelling and Exergy Analysis of Conventional Forging Deformati...

The present paper examines the deformation behaviour of geometrical specimens of an aluminium alloy undergoing axial compression in a Universal Testing Machine under dry condition. It is observed that researchers have made attempts to investigate alternate specimens for friction calibration. It is found that ring compression test is recommended as the standard test for determination of coefficient of friction, because it gives reliable results. The effect of weight percentage of silicon carbide on microstructure, hardness and upsetting load is studied. The friction factor at die metal interface is evaluated by ring compression tests and its effect on non-uniform deformation is investigated. The experimental results are finally compared with those obtained by FEA simulation and modelling. In order to validate the predictability of these specimens, real experiments on them are carried out. Rings of standard dimensional ratio 6:3:1 in the same machine. Friction predictions from both specimen are found to be in close match, proposed alternate specimen offers a powerful tool for friction prediction in the absence of ring specimen. Some aspects of Exergy calculations have been in the past repeatedly used to quantify the quality and quantity of energy used in thermal energy processes. This attempt to drive a exergy utilization and compare for the first time two entirely different manufacturing processes, material processing by a mechanical method of straining of the material and thermal processing during cold forging of the same mass of the material using exergy formulation as metric. The exergy analysis of material processing is determined by performed work and utilized heat transfer using mechanical and thermal processes

A Review of Vibration of a cantilever Beam

Estimating damping in structure made of different m aterials (steel,brass,aluminum) and processes sti ll remains as one of the biggest challengers. All mate rials posses certain amount of internal damping,wh ich manifested as dissipation of energy from the system . This energy in a vibratory system is either dissipated into heat or radiated away from the syst em. Material damping or internal damping contribute s to about 10-15% of total system damping. Cantilever beams of required size & shape are prepared for experimental purpose & damping ratio is investigate d. Damping ratio is determined by half-power bandwidth method. It is observed that damping ratio is higher for steel than brass than aluminum.

Analysing and Comparing the Behaviours of Cylindrical Fatigue Specimens Made ...

This document analyzes and compares the behaviors of cylindrical fatigue specimens made of nickel-titanium shape memory alloy and steel using finite element analysis in Abaqus. The modal frequencies and deformations were analyzed for the first 20 modes of each material. For both materials, higher order flexions occurred at higher frequencies. Tensile stress was highest in the gauge section and highest for steel due to its higher Young's modulus. The nickel-titanium alloy specimen had a lower maximum frequency, energy, and tensile stress compared to steel. Shape memory alloys are implemented in structures for vibration control and energy dissipation during earthquakes.

Stress vs. Strain Curve

The document discusses how to determine the mechanical properties of a material from a stress-strain curve generated by a uniaxial tensile test. A cylindrical material sample is placed in a tensile testing machine and force is applied to elongate the sample while measuring changes in length. A graph of applied stress versus strain is generated and used to identify properties like proportional limit, elastic limit, yield strength, ultimate strength, and modulus of elasticity. The stress-strain curve also indicates whether a material is brittle or ductile based on its percent elongation. Mechanical properties determined from this process guide material selection based on strength, stiffness, and ductility requirements.

Som

This document provides an introduction to strength of materials (SOM). It defines key terms like strength, stiffness, stability, and durability. It discusses the basic problem in SOM as developing methods to design structural elements that consider strength, stiffness, stability, and economy. It also outlines the main hypotheses in SOM, including the material being continuous, homogeneous, and isotropic. It then discusses different types of stresses like tensile, compressive, and shear stresses. It provides stress-strain curves for ductile materials and defines modulus of elasticity. Examples of calculating stresses and strains in structural elements are also provided.

Tensile testing-laboratory

1) Tensile tests were conducted on four materials: A-36 steel, 6061-T6 aluminum, polycarbonate, and PMMA. The tests determined properties like ultimate tensile strength, modulus of elasticity, and yield strength.

2) A-36 steel had the highest ultimate tensile strength and true fracture strength, while 6061-T6 aluminum had a higher yield strength than steel. Polycarbonate was the most ductile.

3) Engineering stress-strain curves were plotted from the test data and used to calculate material properties like modulus of resilience and toughness.

Stress analysis in chair- Case study

This document presents a case study on stress analysis of a chair frame conducted by mechanical engineering students. The study involves creating a 3D CAD model of a chair frame, selecting mild steel as the material, and conducting finite element analysis in ANSYS to analyze stresses on the frame under different loads. The results show that as load increases, stress, strain, and deformation also increase proportionally. Comparison of FEA results with theoretical calculations verifies the analysis. The conclusion is that stress on the frame decreases with increasing frame dimensions under the same load.

Lab3report

This document summarizes a lab where students used an Instron Universal Testing Machine to perform tensile and compressive tests on various materials to generate stress-strain plots and determine material properties. Students tested an unknown metal, carbon fiber, nylon, and plaster of paris. They identified the unknown metal as grade 340 X steel based on its mechanical properties. Analysis of the stress-strain plots and material properties showed carbon fiber has the highest specific strength and stiffness. The document outlines the procedures, results, and conclusions from the material testing and analysis.

Material Modelling of PVC for Change in Tensile Properties with Variation in ...

This document describes material modelling of PVC plastic to account for changes in tensile properties with variations in strain rate. Tensile tests were conducted on PVC specimens at different strain rates (500 mm/min, 50 mm/min, 10 mm/min) according to ASTM standards. The stress-strain curves from testing showed the yield point shifting with increasing strain rate, indicating PVC modulus does not change with strain rate. The data was used to develop a linear fit equation relating yield strength to the log of strain rate for the PVC material model in LS-DYNA software. Validation simulations were performed and stress-strain curves compared to experimental data to refine the material model.

IRJET-Analysis of Functionally Graded Thick Walled Truncated Cone Pressure Ve...

This document analyzes the stresses in thick-walled truncated conical pressure vessels made of functionally graded materials (FGM) using finite element analysis in ANSYS. It first provides background on FGMs and discusses previous analytical research on stresses in cylindrical and spherical pressure vessels with exponentially varying material properties. It then outlines the problem formulation, modeling of material properties, geometry, and finite elements in ANSYS. Validation of the finite element model is discussed. The goal is to determine how non-homogeneous, exponentially varying material properties in FGM pressure vessels impact induced stresses compared to homogeneous materials.

Thesis - Design a Planar Simple Shear Test for Characterizing Large Strange B...

This document presents the results of a finite element analysis of a tensile loaded shear sample used to characterize the large strain behavior of sheet metals. The analysis validated that the gauge section experiences a state of simple shear. Additional simulations examined the effects of mesh sensitivity, fillets in the gauge section corners to reduce stress concentrations, and a smaller gauge section aspect ratio. The tensile loaded shear sample was concluded to produce a simple shear state in the gauge section.

Gw3412651271

International Journal of Engineering Research and Applications (IJERA) is a team of researchers not publication services or private publications running the journals for monetary benefits, we are association of scientists and academia who focus only on supporting authors who want to publish their work. The articles published in our journal can be accessed online, all the articles will be archived for real time access.

Our journal system primarily aims to bring out the research talent and the works done by sciaentists, academia, engineers, practitioners, scholars, post graduate students of engineering and science. This journal aims to cover the scientific research in a broader sense and not publishing a niche area of research facilitating researchers from various verticals to publish their papers. It is also aimed to provide a platform for the researchers to publish in a shorter of time, enabling them to continue further All articles published are freely available to scientific researchers in the Government agencies,educators and the general public. We are taking serious efforts to promote our journal across the globe in various ways, we are sure that our journal will act as a scientific platform for all researchers to publish their works online.

SPH4.pptx

The document summarizes several studies on simulating friction stir welding and processing using meshfree methods like smoothed particle hydrodynamics (SPH). It discusses how Pan et al. used SPH to model each particle as a representative volume element and coupled it with crystal plasticity modeling. It also summarizes studies by Ansari et al. on modeling the plunging phase and how rotational speed affects stresses and strains, and Xiao et al.'s modified SPH model to simulate heat transfer. Material models used for aluminum alloys in the simulations are also outlined.

Thank you for the presentation, there are some things I would like.docx

Thank you for the presentation, there are some things I would like to point out that I don't think are mentioned in the power point slides you prepared.

For questions 3 it says that I have to give three suitable examples to discuss the importance of shape and materials in the design and manufacture of engineering structures to achieve their mechanical functions and optimal performance -> you only mentioned one or two examples only it says that we need three examples, so can please make them three examples and explain more about each example according to the question that has been asked?

For question 4 it says that we need to propose a novel materials with cross section shape / structure function which we think they have higher bending resistance and torsion resistance per unit area, 2 concepts for each case explaining where your ideas came from and the rationale behind them, ways to test them and targeted applications -> you have mentioned two examples however you did not mention where your ideas came from and the rationale behind them. You also mentioned ways of testing them and their targeted applications; however you did not go in depth. So can I ask you please to do the slides in a way that answers every components mentioned in the question and include the missing parts that you did not include in the presentation.

OVERALL

hello I asked my teacher and he told me there is a mistakes in point 3 and 4. 3. Using suitable examples (at least three), discuss the importance of shape and materials in the design and manufacture of engineering structures in order to achieve their mechanical functions and optimal performances (3-5 slides). (30%)

you can use this example 1-tennis racket 2-bicycle frame.3-pressure vessel.

4. Latest development of 3D printing and composite materials have opened up the possibility to produce very complex shapes/structures which can’t be produced through traditional manufacture process (e.g. machining), propose potential novel materials with new cross-section shape/ structure/functions, which you think may give a higher bending resistance and torsion resistance per unit area. (Minimum 2 concepts each case, ideally in solid work sketch). Explain where your ideas come from and the rational behinds them, propose ways to test your ideas and targeted applications (4-8 slides) (20%).

Also I attached a file that can help you do the last two point 3 ad 4

Accident Prevention Plan

(Your Name)

TECH 462 –Industrial Safety Engineering

(Date)

Table of Contents

Introduction

Purpose & Intentions Page x

Company Presidents Statement Page x

Management Responsibilities

Manager Responsibilities Page x

Supervisors Responsibilities Page x

Employee Orientation

How and When Page x

Emergency Action Plan Page x

Emergency Shutdown Procedures Page x

Injury and Illness Procedures

Procedures Page x

Record Keeping Page x

Supervisor Responsibilities Page x

Repo ...

1-tension.pdf

The static tension test determines the strength of a material when subjected to stretching. A standard test specimen is pulled slowly until failure using a testing machine. The shape is usually round, square, or rectangular. Dimensions depend on standards but the gage length must have a uniform cross-section. The stress-strain diagram is analyzed to determine properties like yield stress, tensile strength, elongation, modulus of elasticity, and toughness. True stress and true strain consider changes in cross-sectional area during plastic deformation.

Similar to SURP_Poster_2016 (20)

Experiment 4 - Testing of Materials in Tension Object .docx

Experiment 4 - Testing of Materials in Tension Object .docx

FE Simulation Modelling and Exergy Analysis of Conventional Forging Deformati...

FE Simulation Modelling and Exergy Analysis of Conventional Forging Deformati...

Analysing and Comparing the Behaviours of Cylindrical Fatigue Specimens Made ...

Analysing and Comparing the Behaviours of Cylindrical Fatigue Specimens Made ...

Material Modelling of PVC for Change in Tensile Properties with Variation in ...

Material Modelling of PVC for Change in Tensile Properties with Variation in ...

IRJET-Analysis of Functionally Graded Thick Walled Truncated Cone Pressure Ve...

IRJET-Analysis of Functionally Graded Thick Walled Truncated Cone Pressure Ve...

Thesis - Design a Planar Simple Shear Test for Characterizing Large Strange B...

Thesis - Design a Planar Simple Shear Test for Characterizing Large Strange B...

Thank you for the presentation, there are some things I would like.docx

Thank you for the presentation, there are some things I would like.docx

SURP_Poster_2016

- 1. Origami Based Metamaterials with Impact Mitigation Applications Riley Pratt PI: Dr. Jinkyu Yang Mentor: Hiromi Yasuda Laboratory for Engineered Materials and Structures Why Origami? References Acknowledgments Prototype Testing Conclusions and Future Work 1. H. Yasuda, and J. Yang. PRL 114, 185502 (2015). 2. H. Yasuda, T. Yein, T. Tachi, K. Miura, and M. Taya, Proc. R. Soc. A 469, 20130351 (2013). Mentors: Dr. Yang, and Hiromi Yasuda Funding: The Washington NASA Space Grant Consortium Facilities: CoMotion MakerSpace 2D • 3D structures can be created by folding 2D sheets, thus simplifying the manufacturing process. Geometry Dictates Material Properties • By changing the geometry of the folding pattern, the material properties can be manipulated (stiffness, Poisson’s ratio, etc.). Tachi-Miura Polyhedron (TMP) Folding motion of the TMP. Rigid foldability Enclosed volume changes with folding motion Tunable Poisson’s ratio Predicted force vs. displacement curve for α = 70˚ . Unique pattern of strain hardening and softening shows the structure can be used in situations requiring negative and positive stiffness Experimental testing apparatus. Compression Tests Decompression Tests Testing results from three decompression tests and four compression tests. Zero displacement represents unfolded initial height (prototype height is 188 mm). Experimental data follows a similar trend to predicted behavior The predicted strain softening (negative slope) was experimentally confirmed Current experimental results confirm the strain hardening and softening behavior of the TMP but are quantitatively unreliable, and further testing is required to experimentally verify the analytical results Friction in the experimental apparatus needs to be reduced to increase test reliability A new prototype that is more conducive to compression tests needs to be designed A consistent method of comparison between analytical and experimental results must be developed Applications: Impact mitigation and absorption (bulletproof vests, sports helmets, variable stiffness pneumatic springs, etc.)