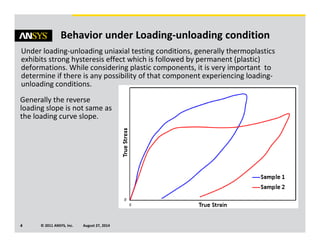

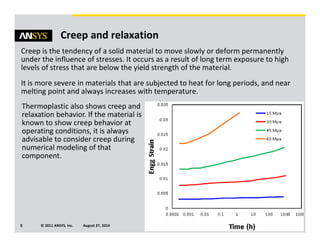

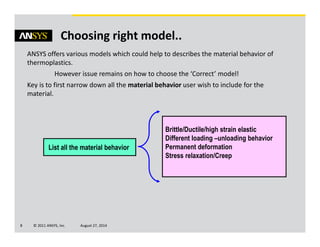

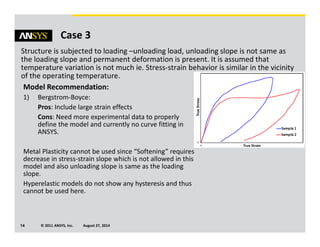

The document discusses modeling the behavior of thermoplastics in ANSYS. It describes the stress-strain behavior of thermoplastics under different loading conditions such as uniaxial tension, loading-unloading, creep, and relaxation. It also lists several material models in ANSYS that can be used to model different thermoplastic behaviors, such as elastic-plastic, hyperelastic, viscoelastic, and viscoplastic models. It provides guidance on choosing the appropriate material model based on the available experimental data, operating loading conditions, and simulation objectives.