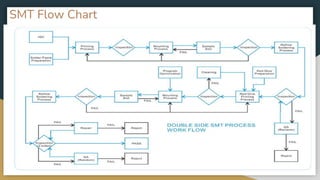

The document provides an overview of Surface Mount Technology (SMT), detailing the process from design and component placement to final inspection and packaging. Key manufacturers such as Fuji Corporation, which leads in SMT equipment, are highlighted, along with specific products like the NXT III mounter and GPX series printer that emphasize efficiency and accuracy. Additionally, the Nexim software is introduced, focusing on production management and operational efficiency.