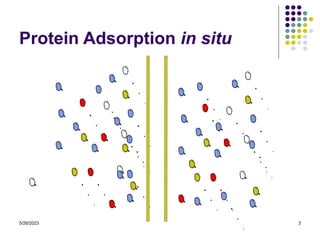

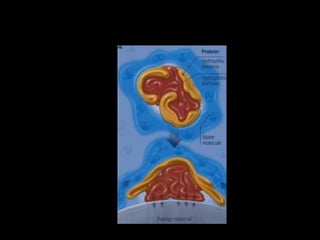

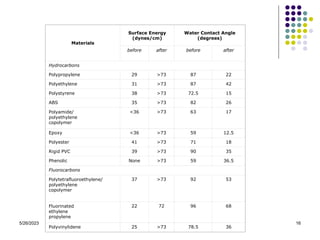

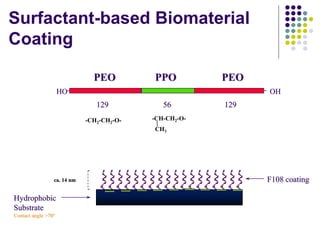

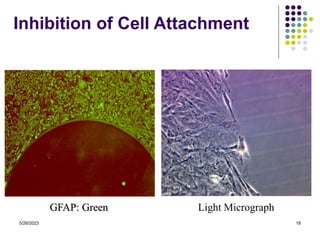

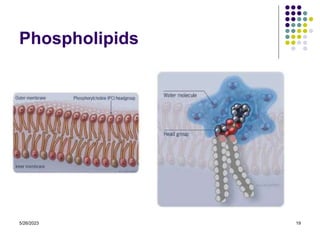

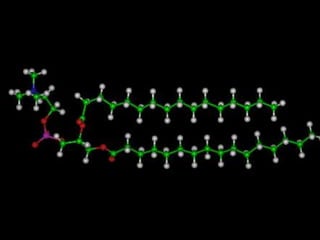

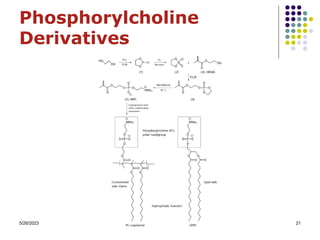

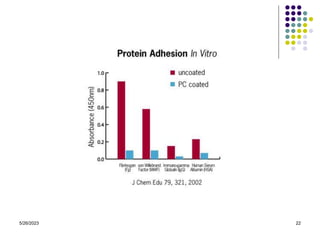

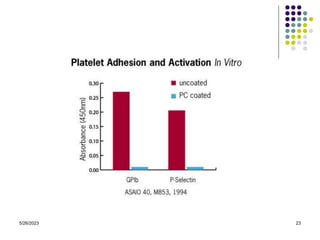

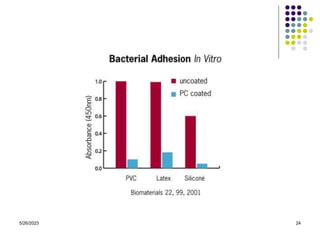

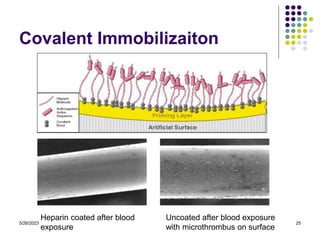

Surface coating technology can be used to alter the binding properties of materials to improve device performance and prevent infections. Common coating methods include plasma treatment, adsorption, and covalent immobilization. Plasma treatment uses gas plasma to modify surfaces without damaging bulk properties. Specific coatings like phosphorylcholine derivatives and surfactant-based coatings can create non-fouling, slippery interfaces that prevent protein adsorption and cell attachment. Coatings are also being developed for applications like enhanced imaging, drug delivery, and tissue engineering.