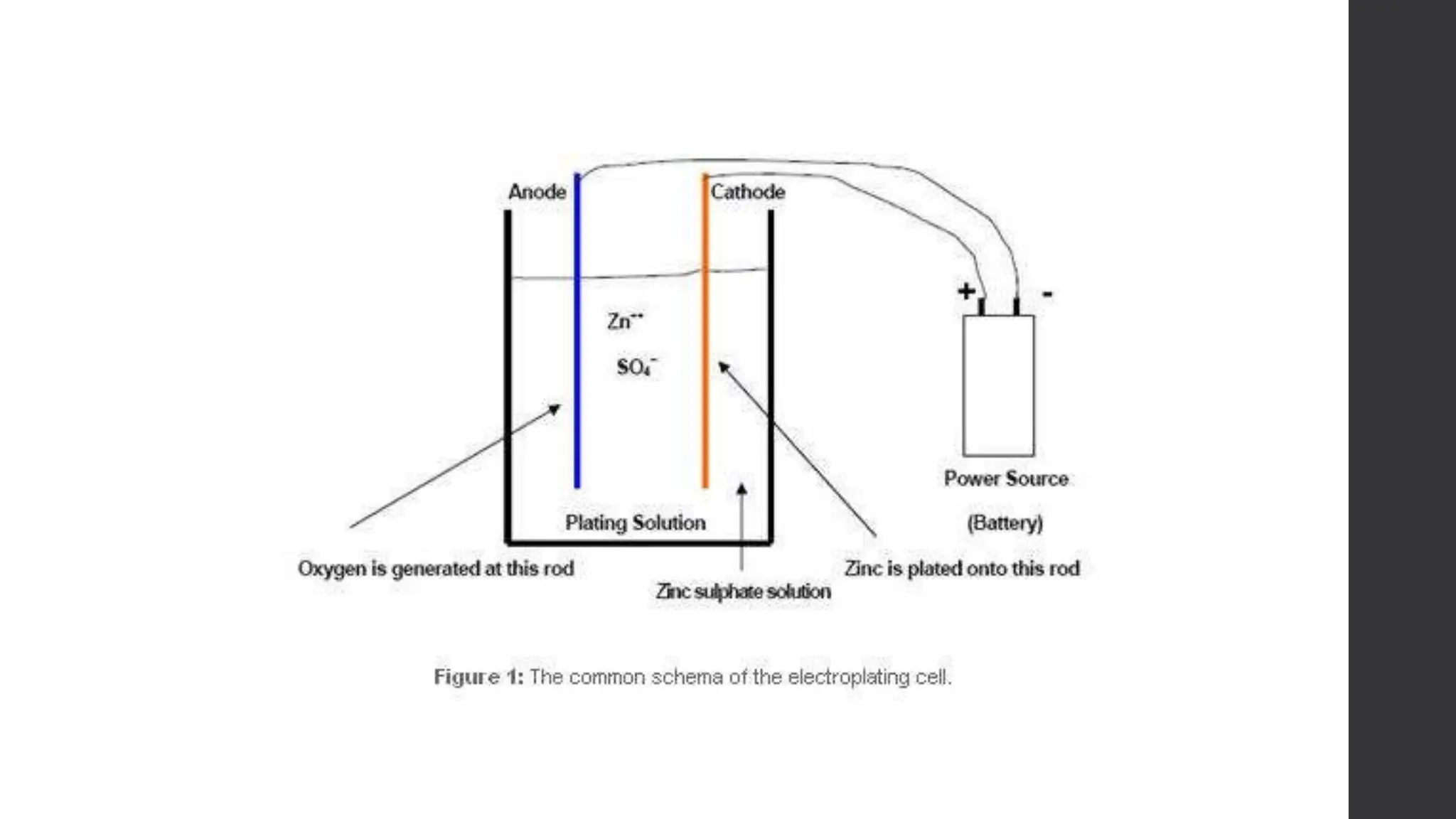

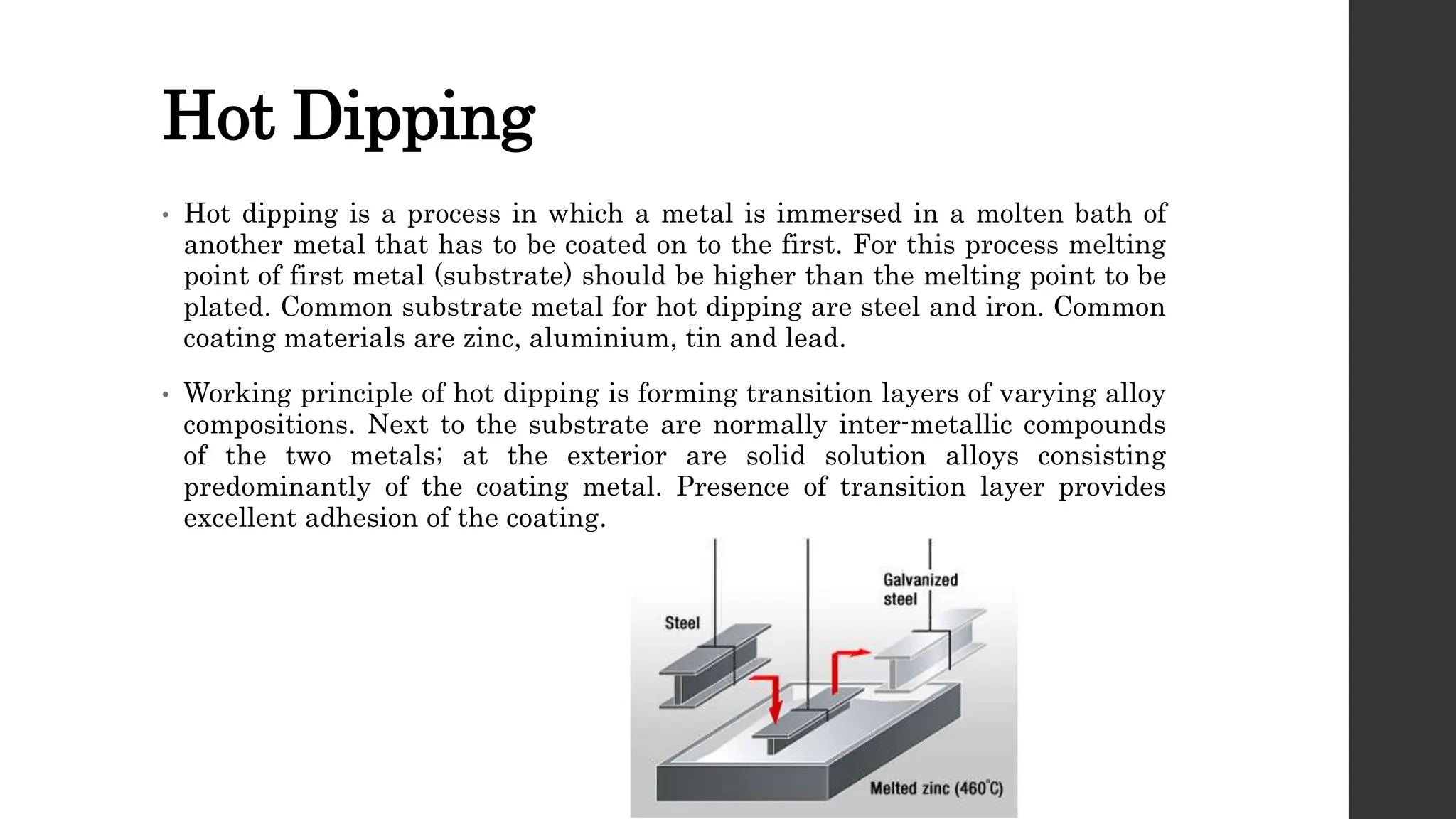

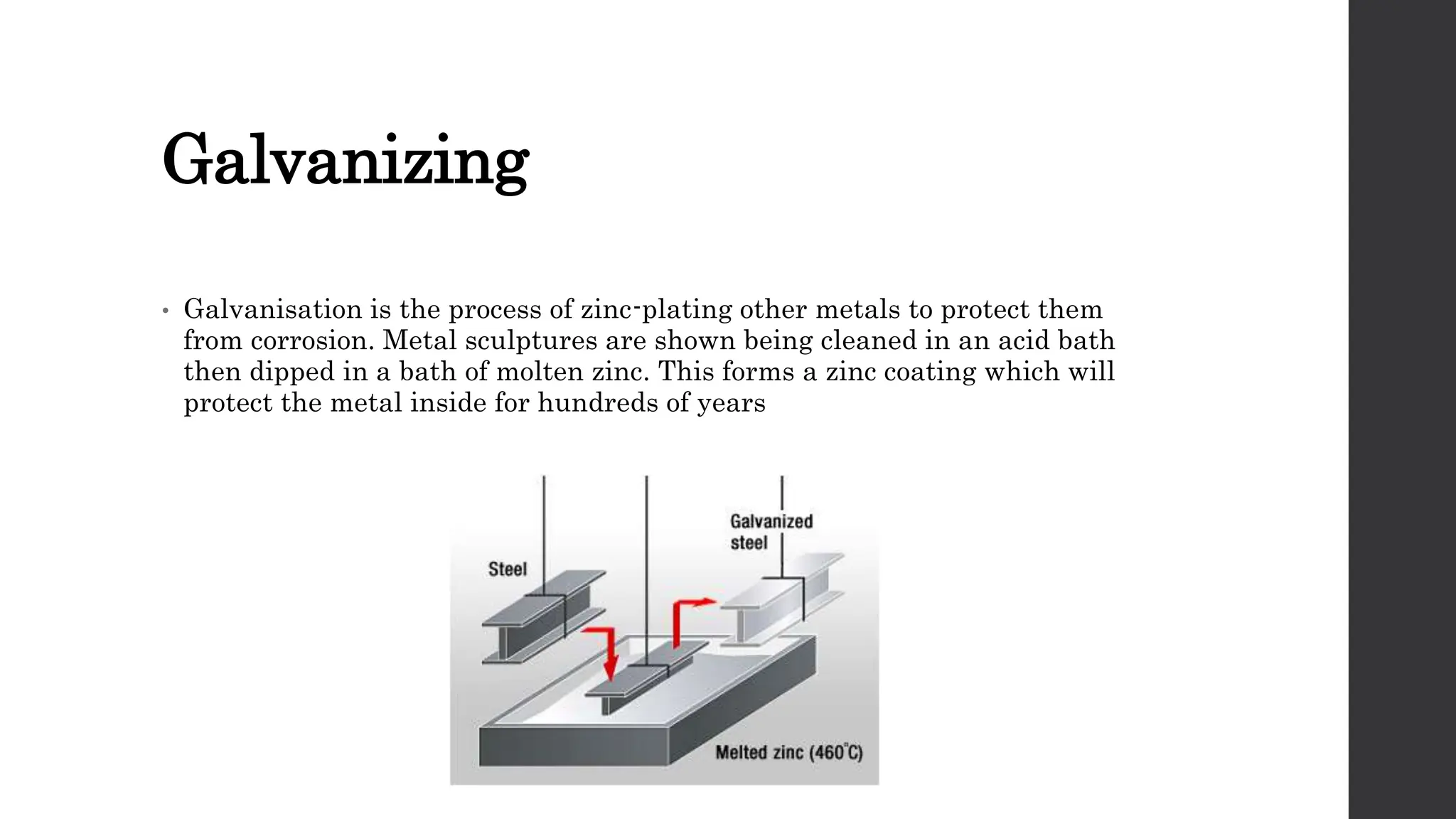

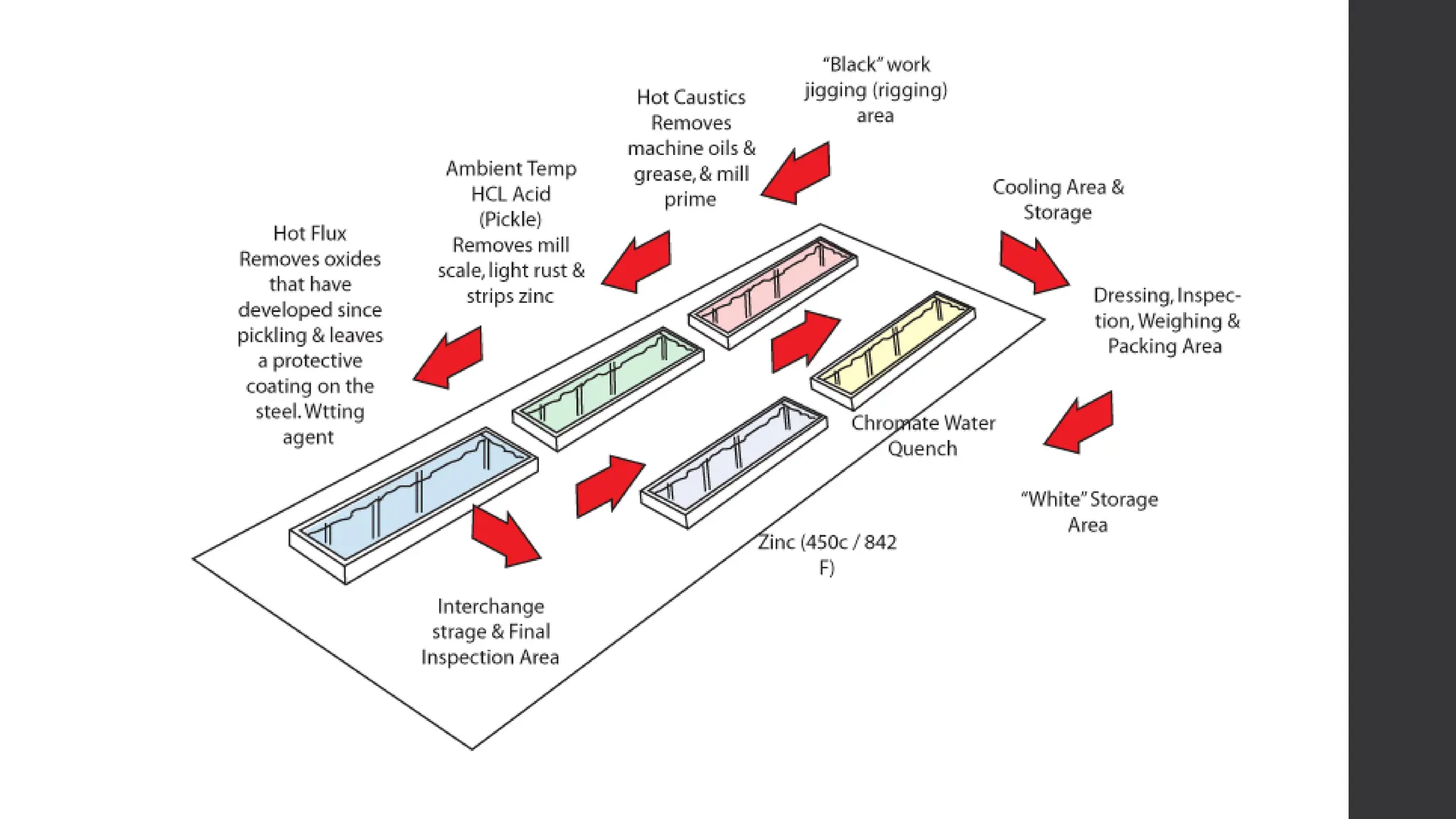

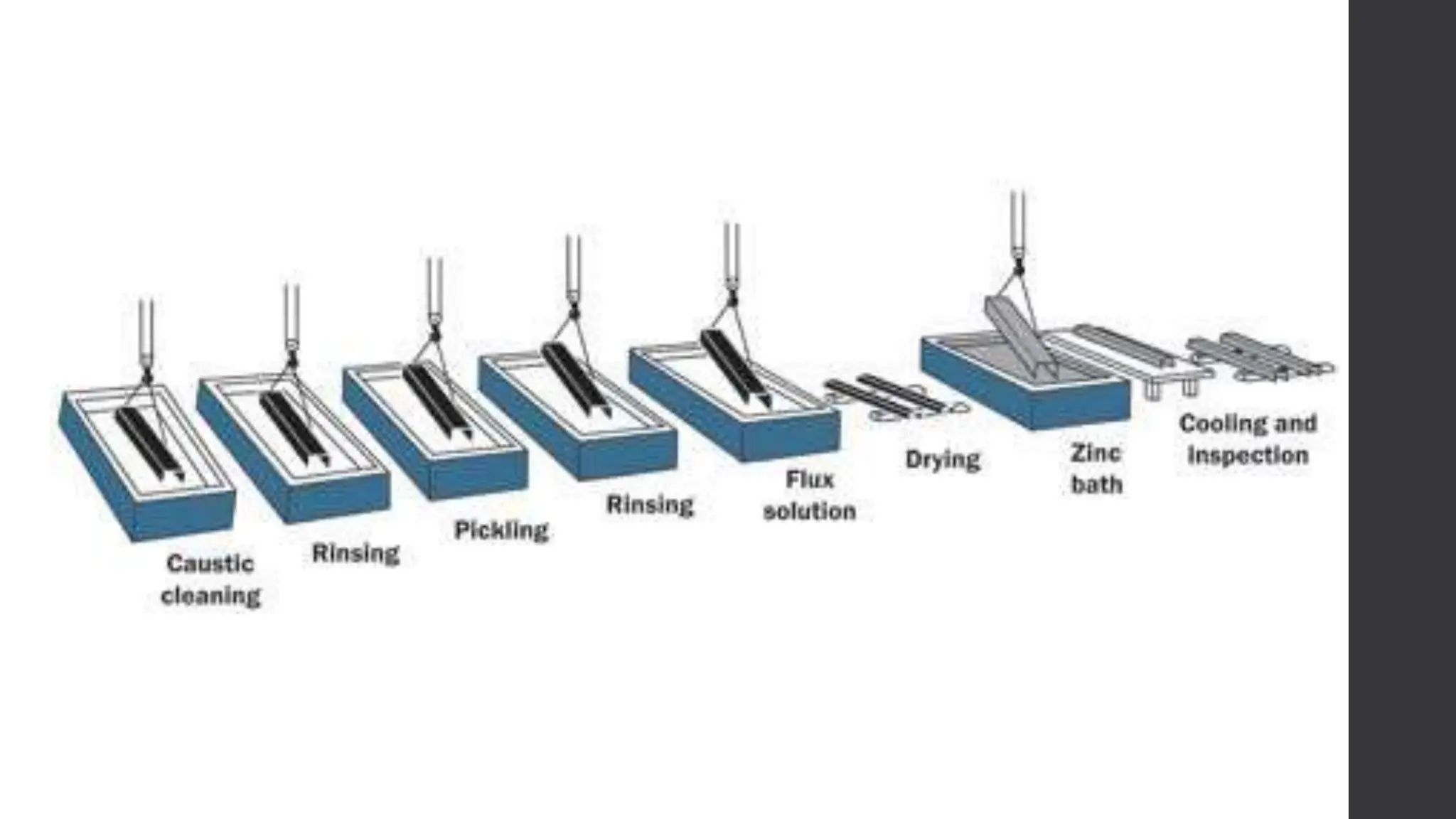

This document provides an overview of surface coating technology. It discusses metallic and non-metallic coatings, comparing their materials and applications. Several coating processes are described, including electroplating, electroless plating, hot dipping, and wire spraying. Electroplating involves depositing metal ions onto a cathode using an electrolytic process. Common metals plated include zinc, nickel, gold, chrome, and tin. Electroless plating is a chemical process that plates without electricity. Hot dipping involves immersing a substrate in molten coating metal.

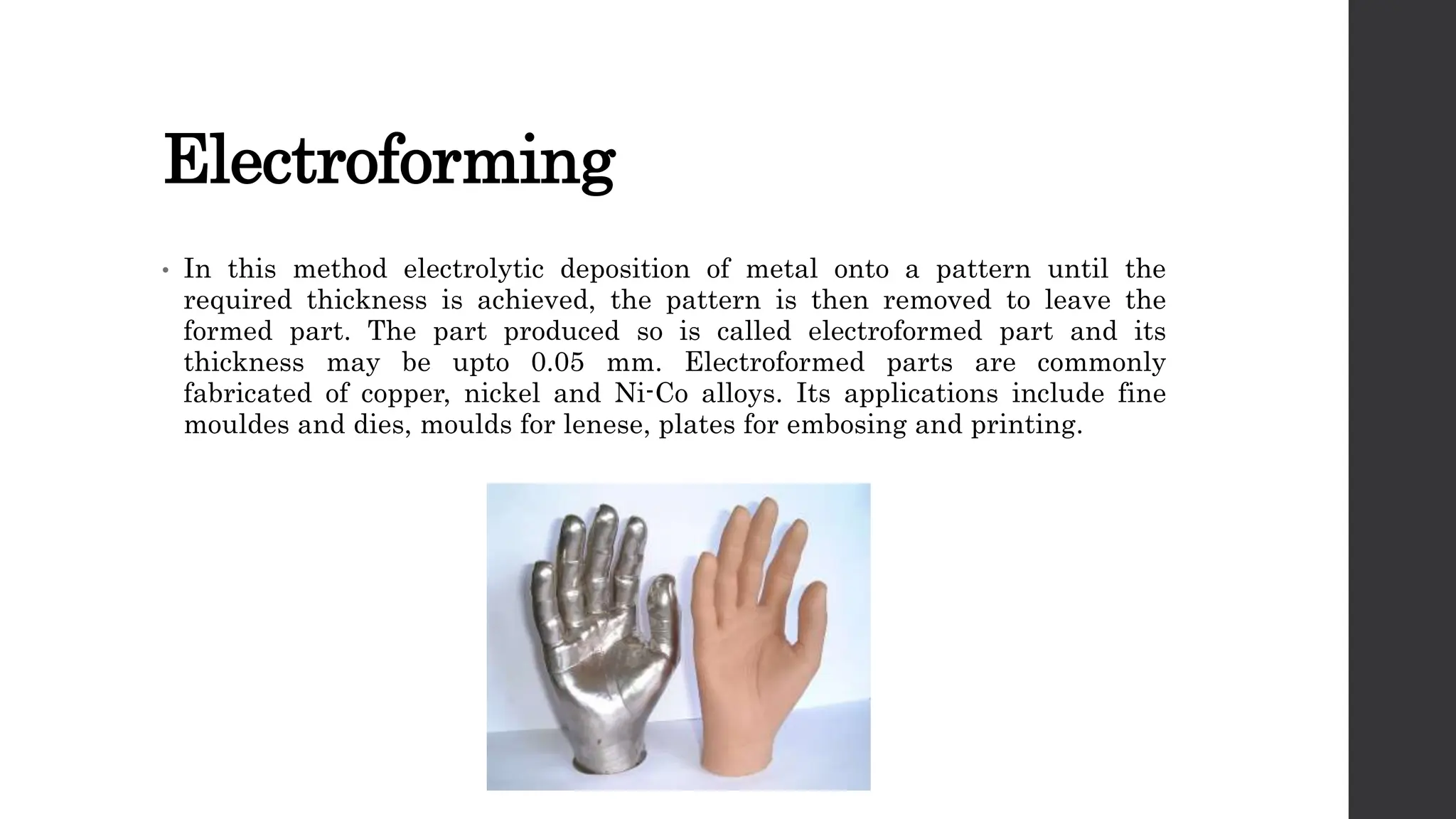

![Sherardising

• Sherardizing is a process of galvanization of ferrous metal surfaces, also

called vapour galvanising and dry galvanizing

• This process involves heating the steel parts up to ca. 500°C in a closed

rotating drum that also contains metallic zincdust and possibly an inert

filler, such as sand.[5] At temperatures above 300°C, zinc evaporates and

diffuses into the steel substrate forming diffusion bonded Zn-Fe-phases

• Sherardising is ideal for small parts and parts that require coating of inner

surfaces, such as batches of small items. Part size is only limited by the

drum size. It is reported that pipes up to 6 m in length for the oil industry

are sherardised

• During and shortly after World War I, German 5 Pfennig and 10 Pfennig

coins were sherardised](https://image.slidesharecdn.com/surfacecoatingtechnology-240119161828-0a3a82be/75/Surface-coating-technology-mechanical-engineering-pptx-37-2048.jpg)

![Electroplating Galvanising

• Electrogalvaning is a process in which a layer of zinc is bonded to steel in

order to protect against corrosion. The process involves electroplating,

running a current of electricity through a saline/zinc solution with

a zinc anode and steel conductor

• Zinc electroplating maintains a dominant position among other

electroplating process options, based upon electroplated tonnage per annum.

According to the International Zinc Association, more than 5 million tons are

used yearly for both Hot Dip Galvanizing and Electroplating.[1] ThePlating of

Zinc was developed at the beginning of the 20th century

• The corrosion protection afforded by the electrodeposited zinc layer is

primarily due to the anodic potential dissolution of zinc versus iron (the

substrate in most cases). Zinc acts as a sacrificial anode for protecting the

iron (steel).

• Steel is preserved from corrosion by cathodic protection electroplated zinc

articles may receive a topcoat to further enhance corrosion protection and

friction performance](https://image.slidesharecdn.com/surfacecoatingtechnology-240119161828-0a3a82be/75/Surface-coating-technology-mechanical-engineering-pptx-39-2048.jpg)