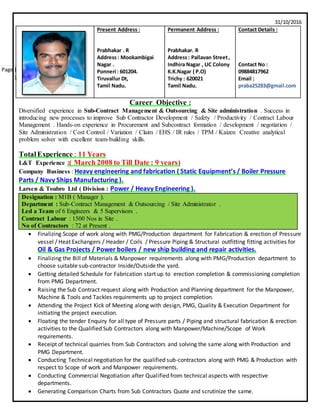

Prabhakar R provides his contact information and career objective of gaining diversified experience in sub-contract management, outsourcing, and site administration. He has over 11 years of experience, including 9 years at Larsen & Toubro Ltd in sub-contract management, outsourcing, and site administration roles. His responsibilities included finalizing scopes of work, raising sub-contracts, awarding contracts, and ensuring on-time payment to contractors. Prior to L&T, he worked as a design engineer for 3 years at BGR Energy Systems manufacturing heat exchangers and pressure vessels. He holds a B.Tech in Mechanical Engineering and has undergone various management and technical trainings.