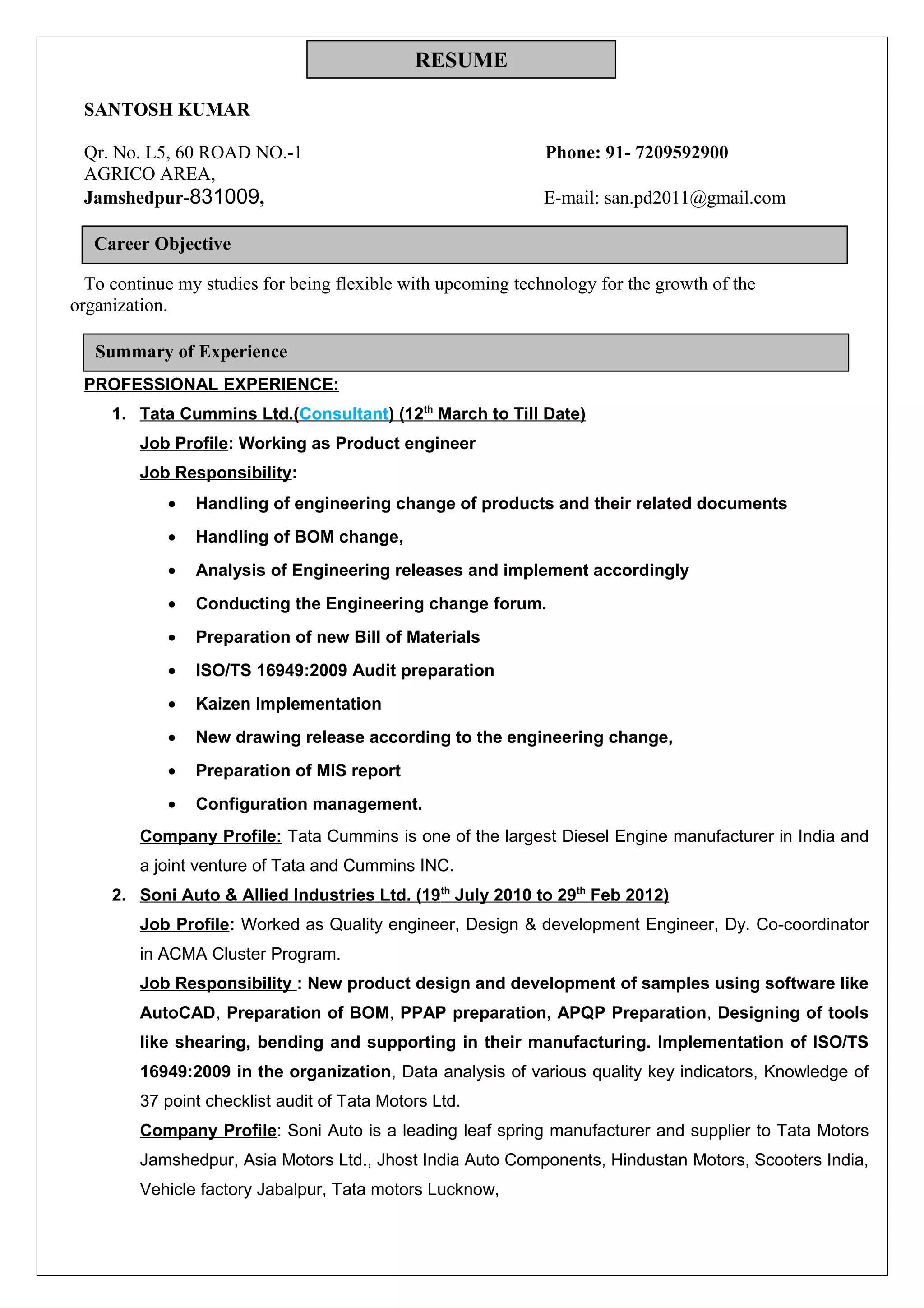

(1) Santhosh Kumar is applying for a job and provides his resume which details his professional experience, qualifications, and skills. (2) He has over 5 years of experience in roles such as Product Engineer, Quality Engineer, and Design Engineer and has worked for companies like Tata Cummins, Soni Auto & Allied Industries, and Auro Works Pune. (3) His experiences include handling engineering changes, quality audits, new product design and development, mold design, and implementation of quality management systems.