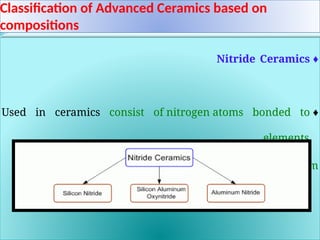

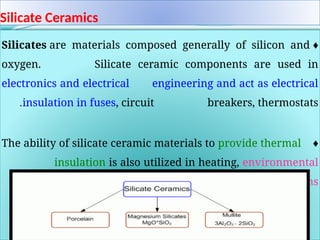

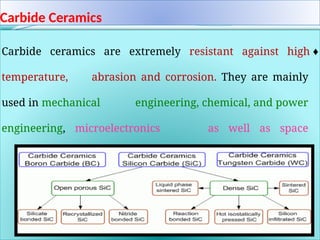

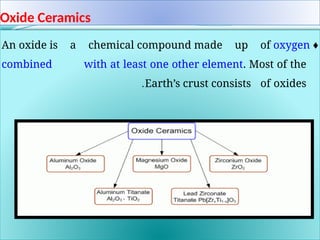

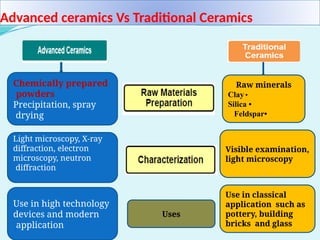

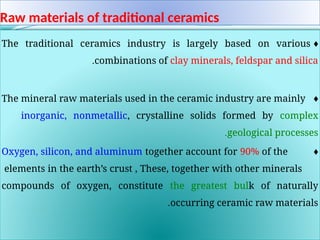

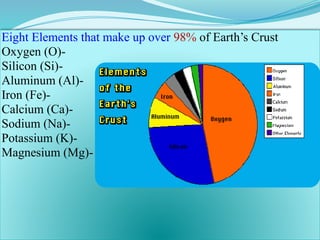

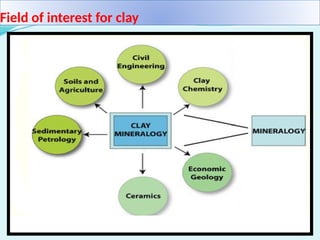

The document discusses advanced ceramics and their classifications, highlighting their industrial applications and the unique properties that make them suitable for various uses, such as in electronics and aerospace. It covers types of advanced ceramics, including conducting, dielectric, piezoelectric, and bio-ceramics, detailing their specific characteristics and manufacturing challenges. Additionally, the text contrasts advanced ceramics with traditional ceramics, emphasizing differences in composition and applications.

![Piezoelectric ceramics

♦

Piezoelectricity is a property of certain classes of crystalline

materials including Barium Titanate BaTiO3 and Lead

Zirconate Titanates Pb[ZrxTi1-x]O3(PZT)

.

.

♦

When mechanical pressure is applied to one of these materials,

the crystalline structure produces a voltage proportional to

the pressure. Conversely, when an electric field is applied, the

structure changes shape producing dimensional changes in

the material

.

♦

Use as sensors , actuators and transducers

.](https://image.slidesharecdn.com/advancedceramics-240821192548-2e02c0f1/85/Advanced-Ceramics-for-different-applications-pptx-7-320.jpg)

![Magnetic ceramics

♦

Magnetic ceramics are made of ferrites, which are

crystalline minerals composed of iron oxide in

combination with some other metal. They are given

the general chemical formula M(FexOy), M

representing other metallic elements than iron. The

most familiar ferrite is magnetite, a naturally occurring

ferrous ferrite (Fe[Fe2O4], or Fe3O4) commonly known as

lodestone

.

Ceramic Magnets](https://image.slidesharecdn.com/advancedceramics-240821192548-2e02c0f1/85/Advanced-Ceramics-for-different-applications-pptx-8-320.jpg)