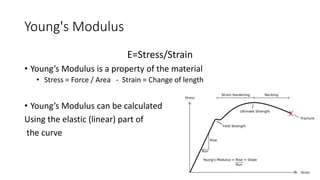

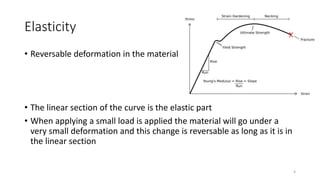

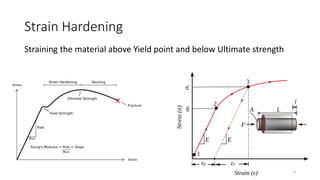

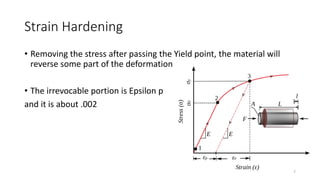

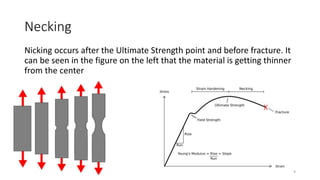

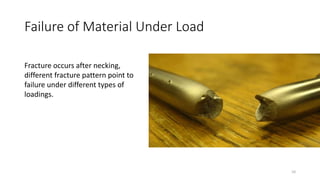

The stress-strain curve provides information about a material's response to stress. It relates the stress placed on a material to the strain or deformation produced. The linear portion of the curve is used to determine Young's modulus, which represents a material's stiffness. Beyond the material's yield point, plastic deformation occurs, which may be partially reversible through strain hardening. Further stress leads to necking and ultimately fracture of the material. Engineers apply a safety factor to account for these responses when selecting materials and designing structures.