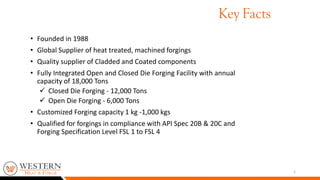

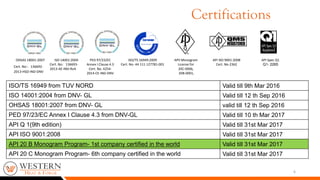

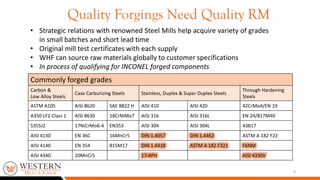

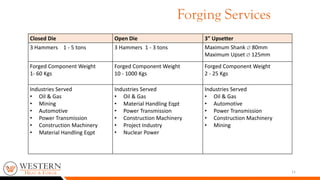

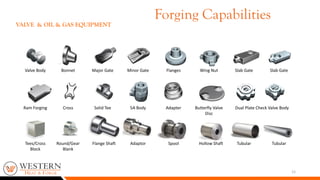

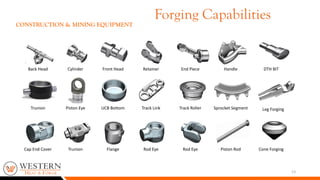

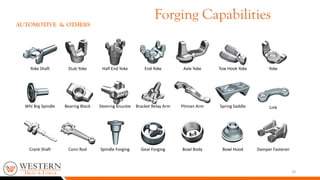

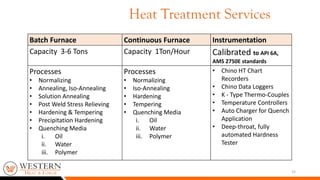

Western Heat & Forge is an integrated forging and machining facility established in 1988 in India. It has over 400 employees and manufactures heat treated, machined forgings and coated components up to 18,000 tons annually via closed and open die forging. The company serves industries such as oil/gas, mining, automotive and has various certifications. It provides customized forging, heat treatment, machining and coating services to customers.