Estructuras de acero sometidas a ensayes de tension

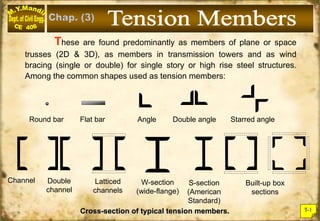

- 1. T-1 These are found predominantly as members of plane or space trusses (2D & 3D), as members in transmission towers and as wind bracing (single or double) for single story or high rise steel structures. Among the common shapes used as tension members: Round bar Flat bar Angle Double angle Starred angle Double channel Channel Latticed channels W-section (wide-flange) S-section (American Standard) Built-up box sections Cross-section of typical tension members.

- 2. T-2 The strength of a tension member is controlled by the lowest of the following limiting states: Net Area (An) Gross Area (Ag) T T A) Yielding of the Gross Area (Ag): Fn = Fy Ag B) Failure (Ultimate strength) on the Net Area (An): Fn = Fu Ae Where Ae = effective net Area = UAn U = Reduction Coefficient. C) Block Shear Failure through the end bolt: T

- 3. T-3 A hole is drilled (or punched) by 1/16 inch greater then the normal diameter of the fastener (rivet or bolt). Hole punching causes some damage to the edges of the hole to the amount of 1/32 inch from each side. Thus the normal hole diameter . 8 1 dia. bolt 32 1 32 1 16 1 diameter bolt inch

- 4. T-4 What is the net area An for the tension member as shown in the figure? Solution: T T Ag = 4(0.25) = 1.0 sq in. Width to be deducted for hole An = [Wg – (width for hole)] (thickness of plate) . in 8 7 8 1 4 3 Standard Hole for a -in. diam bolt. 4 3 4 4 1 Plate (inches) Example (T1): in. sq. 78 . 0 25 . 0 8 7 4

- 5. (a) (b) T-5 For a group of staggered holes along the tension direction, one must determine the line that produces smallest “Net Area”. Paths of failure on net section EFFECT OF STAGGERED HOLES ON NET AREA :- T T B A T T s g A C p p p B In the above diagram: p = Pitch or spacing along bolt line s = Stagger Between two adjacent bolt lines (usually s = P/2) g = gage distance transverse to the loading. In case (a) above : An = (Gross width – Σ hole dia.) . t In case (b) above : An = (Gross width – Σ hole dia.+ Σ s2/4g) . t

- 6. T-6 Determine the minimum net area of the plate shown in fig. 3.4.2, assuming in,-diam holes are located as shown: Figure 3.4.2 Example 3.4.1 16 15 Example (T2):

- 7. T-7 Solution. According to LRFD and ASD-B2, the width used in deducing for holes in the hole diameter plus 1/16 in., and the staggered length correction Is (s2/4g). . . . . in sq 50 2 25 0 16 1 16 15 2 12 1) Path AD (two holes) : 2) Path ABD (three holes; two staggers) : . . . . ) ( ) . ( . . in sq 43 2 25 0 4 4 125 2 5 2 4 125 2 16 1 16 15 3 12 2 2 . . . . ) ( ) . ( . . in sq 42 2 25 0 4 4 875 1 5 2 4 125 2 16 1 16 15 3 12 2 2 3) Path ABC (three holes; two staggers) : (controls)

- 8. T-8 Angles: When holes are staggered on two legs of an angle, the gage length (g) for use In the (s2/4g) expression is obtained by using length between the centers of the holes measured along the centerline of the angle thickness, i.e., the distance A-B in Fig: 3.4.3. Thus the gage distance g is t g g t g t g g b a b a 2 2 Gage dimension for an angle

- 9. T-9 Every rolled angle has a standard value for the location of holes (i.e. gage distance ga and gb), depending on the length of the leg and the number of lines of holes. Table shows usual gages for angles as listed in the AISC Manual*.

- 10. T-10 Determine the net area (An ) for the angle given in figure below if holes are used? Angle with legs shown *flattened* into one plane 4 1 4 2 1 4 1 2 2 1 2 1 t g g * *legs and thickness in mm. . , 16 15 dia in Example (T3): 9½”

- 11. T-11 Solutions. For net area calculation the angle may be visualized as being flattened into a plate as shown in Figure above. t 4g s Dt A A 2 g n where D is the width to be deducted for the hole. 1) Path AC: 2) Path ABC: . . 75 . 3 5 . 0 16 1 16 15 2 75 . 4 in sq . . 96 . 3 5 . 0 ) 25 . 4 ( 4 ) 3 ( ) 5 . 2 ( 4 ) 3 ( 5 . 0 16 1 16 15 3 75 . 4 2 2 in sq Since the smallest An is 3.75 sq in., that value governs. An = An = 9.5"

- 12. T-12 When some of the cross section (and not all the section) is connected, we need to use effective net area concept :- Ae = U An where, U = Reduction Factor. When all elements of the section are connected, U = 1.0.

- 13. When not all elements are connected. i) Transverse Weld Connection:- Ae = UA U = 1.0 A = Area of connected part only e.g. A = 6 x 1/2 = 3 in2 ii) Longitudinal Weld Connection :- Ae = Ag U U = 1.0 for L 2 w U = 0.87 for 2w L 1.5 w U = 0.75 for 1.5w L w 6” Gusset plate Angle 6x4x1/2 T T-13 w Gusset plate Angle 6x4x1/2 T L Weld

- 14. T-14 In bolted connections, the reduction factor (U) is a function of the eccentricity ( ) in the connection. B3.2) - (LRFD 9 . 0 1 L x U Thus:- Where: = distance between centroids of elements to the plane of load transfer L = Length of the connection in the direction of load. (See Commentary C – B 3.1 & C – B 3.2) x x

- 15. T-15 x Determination of for U. LFRD Specification for Structural Steel Buildings, December 27, 1999 American Institute of Steel Construction

- 16. T-16 (Commentary P16.1 – 177 AISC) For bolted or riveted connections the following values for (U) may be used:- a) W, M or S Shapes with flange width ≥ 2/3 depth, and structural tees cut from these shapes, provided connection to the flanges and has ≥ 3 fasteners per line in the direction of force, U = 0.90. b) W,M or S Shapes where flanges width < 2/3 depth, and all other shapes, that has no fewer than 3 fasteners per line, U = 0.85 c) All members having only two fasteners in the line of stress U = 0.75 For short tension members such as Gusset plates the effective net area equals (An), but must not exceed 0.85 of the gross area (Ag).

- 17. Example (T-4) Calculate the Ae values of the following section:- 7/8 bolts W 8 x 28 → flange width (6.54”) > 2/3 x depth (8.0”) → Three bolts / line U = 0.90 Ag = 8.24 m2 An = gross area – hole area = 8.24 – (2 x 1.0 hole) x web tk 0.285 = 7.68 in2 Ae = U·An = 0.9 x 7.68 = 6.912 in2 hole dia = 7/8 C 9 x 15 only 2 bolts / line, U = 0.75 Ag = 4.41 m2 An = 4.41 – (2 x 15/16) 0.285 = 3.875 in2 Ae = 0.75 x 3.875 = 2.907 in2 (i) (ii) T-17 web tk

- 18. (iii) x L 3 x 3 x 3/8 3 3 ¾ dia bolt x = 0.888 L = 6 in (3+3) x U = 1 - /L = 1 -0.888/6 = 0.852 < 0.9 Ag = 2.11 in2 An = 2.11 – 1 x (3/4 + 1/8) x 3/8 = 2.11 -0.328 = 1.782 in2 Ae = U·An = 0.852 x 1.782 = 1.518 in2 Alternative value of U = 0.85 (3 bolts / line) (iv) w 10 x 33 7/8 dia. bolt All sides connected U = 1·0 Ag = 9.71 in2 An = 9.71 – 4 x 1.0 x 0.435 – 2 x 1.0 x 0.290 = 9.71 – 1.74 - 0.58 = 7.39 in2 Ae = U·An = 7.39 in2 Holes in flage flage tk hole Holes in web web tk. T-18

- 19. T-19 This third mode of failure is limited to thin plates. This failure is a combination of tearing (shear rupture) and of tensile yielding. It is uncommon, but the code provides on extra limit state of (LRFD J 4.3). It is usually checked after design is completed. (a) Failure by tearing out Gusset Plate Shaded area may tear out T a c b Even as tension members are unlikely to be affected by their stiffness (L/r), it is recommended to limit the maximum slenderness ratio (L/r) for all tension members (except rods) to ≤ 300. Max. slenderness = L/rmin ≤ 300 This is to prevent extra sagging and vibration due to wind.

- 20. The general philosophy of LRFD method: i i n Q R For tension members: u n t T T where t = resistance reduction factor for tensile members Tn = Nominal strength of the tensile members Tu = Factored load on the tensile members. The design strength tTn is the smaller of: a) Yielding in the gross section; t Tn = t Fy Ag = 0.9 Fy Ag b) Fracture of the net section; t Tn = t Fu Ae = 0.75 Fu Ae This is to be followed by check of rupture strength (block shear failure), and limitation of slenderness ratio ≤ 300. T-20

- 21. Example (T-5):- Find the maximum tensile capacity of a member consisting of 2Ls (6 x 4 x ½) can carry for two cases: (a) welded connection, (b) bolted connection 1" dia bolts Fy = 60 ksi Fu = 75 ksi. ½” 5½ 2½” 2” 1¾” 1¾” T-21

- 22. Net area = gross area (all sides connected) = 9.50 in2 Yielding Ft = 0.9 Fy Ag = 0.9 x 60 x 9.50 = 513 k Fracture Ft = 0.75 Fu Ae = 0.75 x 75 x 9.5 = 534 k Thus tension capacity, t Tn = 513 k (yielding controls) (a) welded Connection (b) Bolted Connection Consider one L ‘An’ Calculation: Wg = gross width = 6 + 4 – ½ = 9.5 in. (cont.) T-22

- 23. Straight section : wn = 9.5 – 2 x = 7.25 in. 8 1 1 = 6.62 in. (Controls) (fracture controls) An = 6.62 x ½ = 3.31 in2 for one L For 2Ls, An = 3.31 x 2 = 6.62 in2 All sides connected, U = 1.0, Ae = U.An = 6.62 in2 Calculation of t Tn :- (i) Yielding: 0.9 Fy Ag = 0.9 x 60 x 9.50 = 513 k (ii) Fracture:0.75 Fu Ae = 0.75 x 75 x 6.62 = 372 k. (thickness) T-23 Zig-Zag = 4 4 (1.75) 2.5 4 (1.75) 1 3 9.5 w 2 2 8 1 n (2.5+2–0.5) 2½” 4” 1.75” 1.75” 9½”

- 24. Design is an interactive procedure (trial & error), as we do not have the final connection detail, so the selection is made, connection is detailed, and the member is checked again. Proposed Design Procedure:- i) Find required (Ag) from factored load . ii) Find required (Ae) from factored load . iii) Convert (Ae) to (Ag) by assuming connection detail. iv) From (ii) & (iii) chose largest (Ag) value v) Find required (rmin) to satisfy slenderness vi) Select a section to satisfy (iv) and (v) above. vii) Detail the connection for the selected member. viii)Re-check the member again. y u g 0.9F T A u u e 0.75F T A 300 r L min T-24

- 25. Example (T-6):- A tension member with a length of 5 feet 9 inches must resist a service dead load of 18 kips and a service live load of 52 kips. Select a member with a rectangular cross section. Use A36 steel and assume a connection with one line of 7/8-inch-diameter bolts. Member length = 5.75 ft. T-25

- 26. T-26 Pu = 1.2 D + 1.6L = 1.2(18) + 1.6(52) = 104.8 kips 2 u u e 2 y u g in. 2.409 0.75(58) 104.8 0.75F P A Required in. 3.235 0.90(36) 104.8 0.90F P A Required Because Ae = An for this member, the gross area corresponding to the required net area is t 2.409 t 8 1 8 7 2.409 A A A hole n g Try t = 1 in. Ag = 2.409 + 1(1) = 3.409 in.2

- 27. T-27 Because 3.409 > 3.235, the required gross area is 3.409 in.2, and in. 3.409 1 3.409 t A w g g Round to the nearest 1/8 inch and try a 1 3 ½ cross section. Check the slenderness ratio: Use a 3 ½ 1 bar. (OK) 300 239 0.2887 5.75(12) r L Maximum in. 0.2887 3.5 0.2917 A I r obtain we , Ar I From in. 3.5 1(3.5) A in. 0.2917 12 3.5(1) I min min 2 2 4 3 min

- 28. Select a single angle tension member to carry (40 kips DL) and (20 kips LL), member is (15)ft long and will be connected to any one leg by single line of 7/8” diameter bolts. Use A-36 steel. Solution: Step 1) Find Required (Tu):- Tu = 1.2 DL + 1.6 LL Tu = 1.4 DL = 1.2 x 40 + 1.6 x 20 or = 1.4 x 40 = 48 + 32 = 80k = 56k Tu = 80k (Controls) T-28 Example (T-7):-

- 29. Step 2) Find required Ag & Ae: 1 g 2 y u req. g ) (A in 2.47 36 0.9 80 0.9F T ) (A 2 u req. e in 1.84 58 0.75 80 0.75Fu T ) (A Step 3) Convert (Ae) to (Ag): Since connection to single leg, then use alternative (U) value = 0.85 (more then 3 bolt in a line). 2 in 16 . 2 85 . 0 84 . 1 ) ( U A A e n For single line 7/8” bolts ; Ag = An + (1)t = 2.16 + t = (Ag)2 T-29

- 30. Step 4) Find required rmin. in. 0.6 300 12 15 300 L rmin Step 5) Select angle: By selecting (t) we get Ag & rmin t (Ag)1 (Ag)2 1/4 2.47 2.41 3/8 2.47 2.53 1/2 2.47 2.66 select t = 3/8” (Ag)2 = 2.53 in2 T-30 (Controls)

- 31. Selection 8 3 2 1 3 L4 Ag = 2.67 in2 > 2.53 in2 OK rmin = 0.727 in > 0.6 OK Step 6) Design the bolted connection: (chap. 4). Step 7) Re-check the section. T-31

- 32. Select a pair of MC as shown to carry a factored ultimate load of 490 kips in tension. Assume connection as shown. Steel Fy = 50 ksi, Fu = 65 ksi (A572, grade 50) length = 30 ft. 1. Tu = 490 k; per channel, Tu = 245 k 2. Required, (Ag)1 = 245 / 0.9 x 50 = 5.44 in2 Required, (Ae) = 245 / 0.75 x 65 = 5.03 in2 Required, (An) = = 5.03 in2 U Ae 3. Assume that flange thickness ~ 0.5 in and web tk. ~ 0.3 in. (experience !) An = (Ag)2 – 2 x 1.0 x 0.5 – 2 x 1.0 x 0.3 = (Ag)2 – 1.60 (Ag)2 = An + 1.60 = 5.03 + 1.60 = 6.63 in. (controls) T-32 10” 2MC 7/8” bolt U = 1.0 (Well connected) Example (T-8):-

- 33. 4. Required. rmin = (as a buildup section) 5. Try MC 10 x 25 ; Ag = 7.35 in2 ; tw = 0.38 and tf = 0.575, rx = 3.87 in. 6. Check capacity An = 7.35 – 2 x 1.0 x 0.575 – 2 x 1.0 x 0.38 = 7.35 – 1.910 = 5.44 in2. Ae = 5.44 in2. (i) Yielding Tn = 0.9 x 50 x (2 x 7.35) = 661.5 k (ii) Fracture Tn = 0.75 x 65 x (2 x 5.44) = 530.4 k Pn = 530.4 k > 490 k. OK Use 2 MC 10 x 25 in 2 . 1 300 12 30 300 l rmin ≥ 1.2 T-33 x y x y

- 34. For built-up members, tie plates are required to make the members to behave as a single unit. Between tie plates, each member behaves as a single. Therefore, l/r between tie-plates corresponds to that for a single member. For single , rmin = ry ; ry = 1.0 in 30ft. 25.0ft ft 12 1.0 300 l Max. T-34 (N.G.)

- 35. Note: Tie-Plates must be used at ends. See Manual for min. sizes. Length of tie-plate ≥ 2/3 (dist. between line of connection) = 8" Thickness of tie-plate ≥ 1/50 (dist. between line of connection) = 1/2" T-35 15' 15' Therefore one tie-plate at middle must be used. See LFRD D2. (P. 16.1-24) 24 - P16.1 D2, LRFD