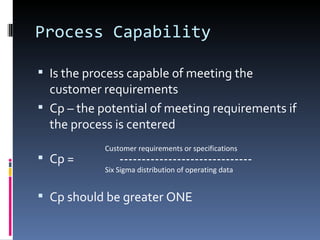

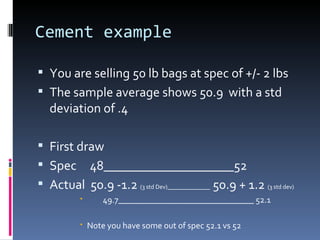

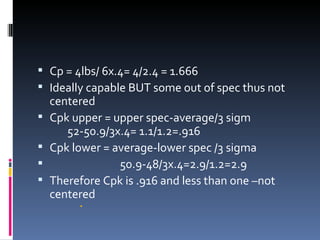

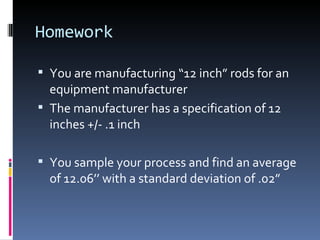

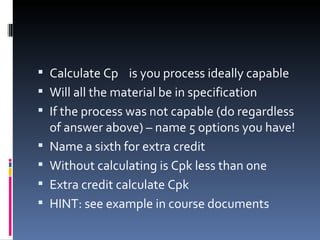

Statistical Process Control (SPC) uses statistics and data distribution to predict process results and improve processes by managing variation. The normal distribution is central to SPC, with most data following a normal "bell curve" distribution. Control charts show when a process is outside normal limits, indicating an assignable cause. Process capability compares actual process performance to customer requirements to determine if the process is capable of meeting specifications.