This document provides an overview of Queensgate, a company that develops nanopositioning systems. Some key points:

- Queensgate was spun off from Imperial College London in 1978 and manufactures precision positioning systems.

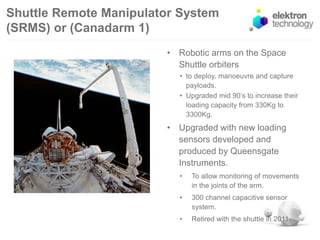

- They have worked on numerous space projects including providing sensors for the Canadarm robotic arms on the Space Shuttle and International Space Station.

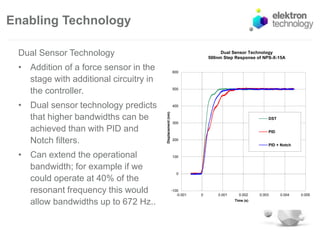

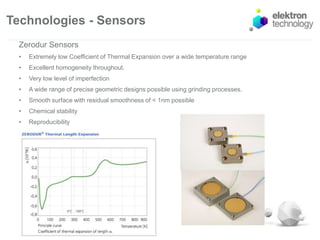

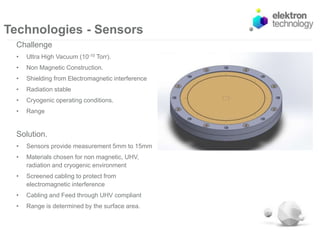

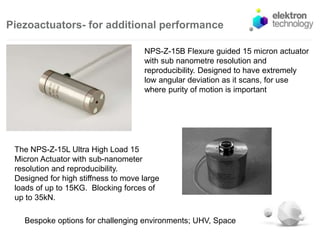

- Their technologies include high-precision tip/tilt mirrors, piezo actuators, and capacitive sensors designed for applications in space, vacuum environments, and cryogenic conditions.

- Queensgate offers customized solutions and has experience designing products that meet the stringent requirements of applications in labs, manufacturing, and space exploration.