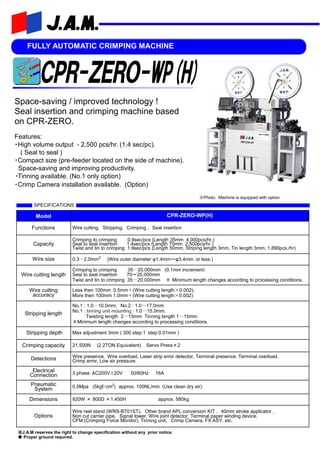

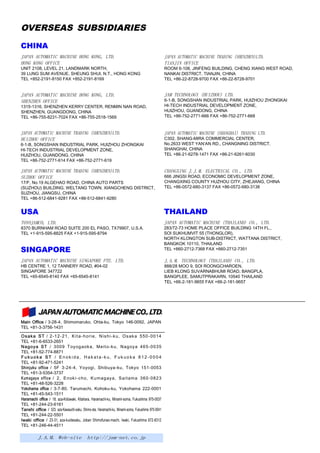

This document contains summaries of several fully automatic and semi-automatic crimping machines and related equipment from J.A.M. It includes specifications for crimping machines that feature high-volume output, compact sizes, and optional features like crimp cameras. It also lists overseas subsidiaries of J.A.M. in locations like Hong Kong and China.