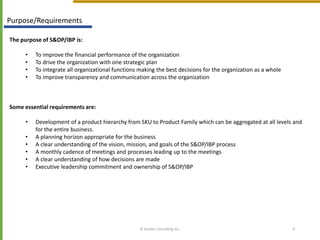

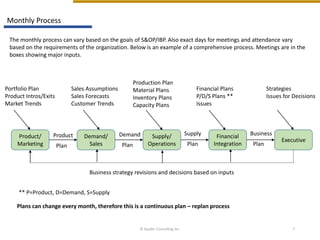

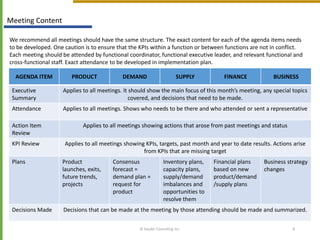

The document discusses Sales & Operations Planning (S&OP) and Integrated Business Planning (IBP). It describes how S&OP evolved over time to include additional business inputs and more rigorous financial analysis. The key aspects of an effective S&OP/IBP process include developing an integrated strategic plan, implementing robust supply chain management, and establishing a monthly cycle of cross-functional planning meetings. The meetings should follow a standard agenda focusing on product plans, demand forecasts, supply plans, financial plans, and business strategy.