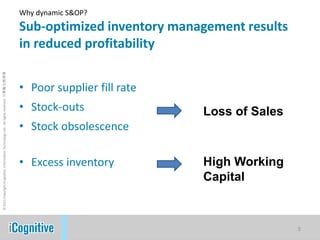

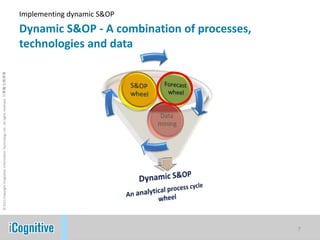

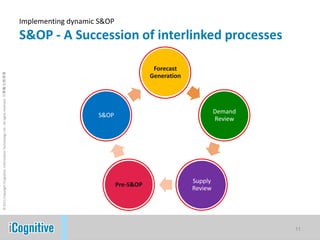

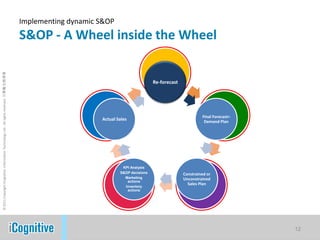

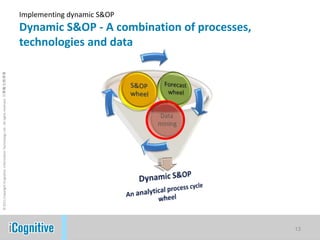

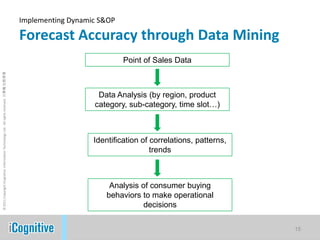

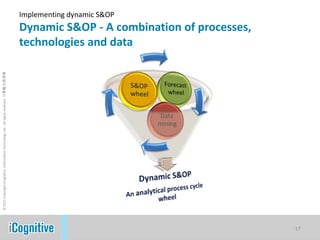

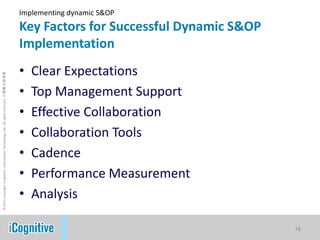

This document discusses the benefits of implementing dynamic sales and operations planning (S&OP). Dynamic S&OP leverages data analysis and collaboration to improve forecasting accuracy and supply chain visibility. It helps companies respond better to volatile market conditions. Key benefits of dynamic S&OP include improved product availability, higher supplier fill rates, reduced inventory obsolescence, increased sales and profits, and enhanced collaboration across the supply chain. The document advocates using data mining of point of sale and other data to analyze customer buying patterns and integrate these insights into the S&OP process for more accurate demand forecasting.