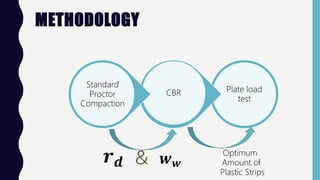

This document discusses using plastic bottle strips to stabilize soil. Unstable expansive soils like black cotton soil cause problems for foundations due to swelling, shrinkage, and unequal settlement. Soil stabilization is done to improve strength and prevent erosion. Plastic is a good stabilizer as it is flexible, water resistant, and provides thermal resistance. Tests on lateritic soil mixed with plastic strips at 0.6% found increased CBR values and reduced settlement under loading compared to unmixed soil, demonstrating plastic's effectiveness as a stabilizer. Using waste plastic bottles in this way provides an economical solution while reducing plastic waste.