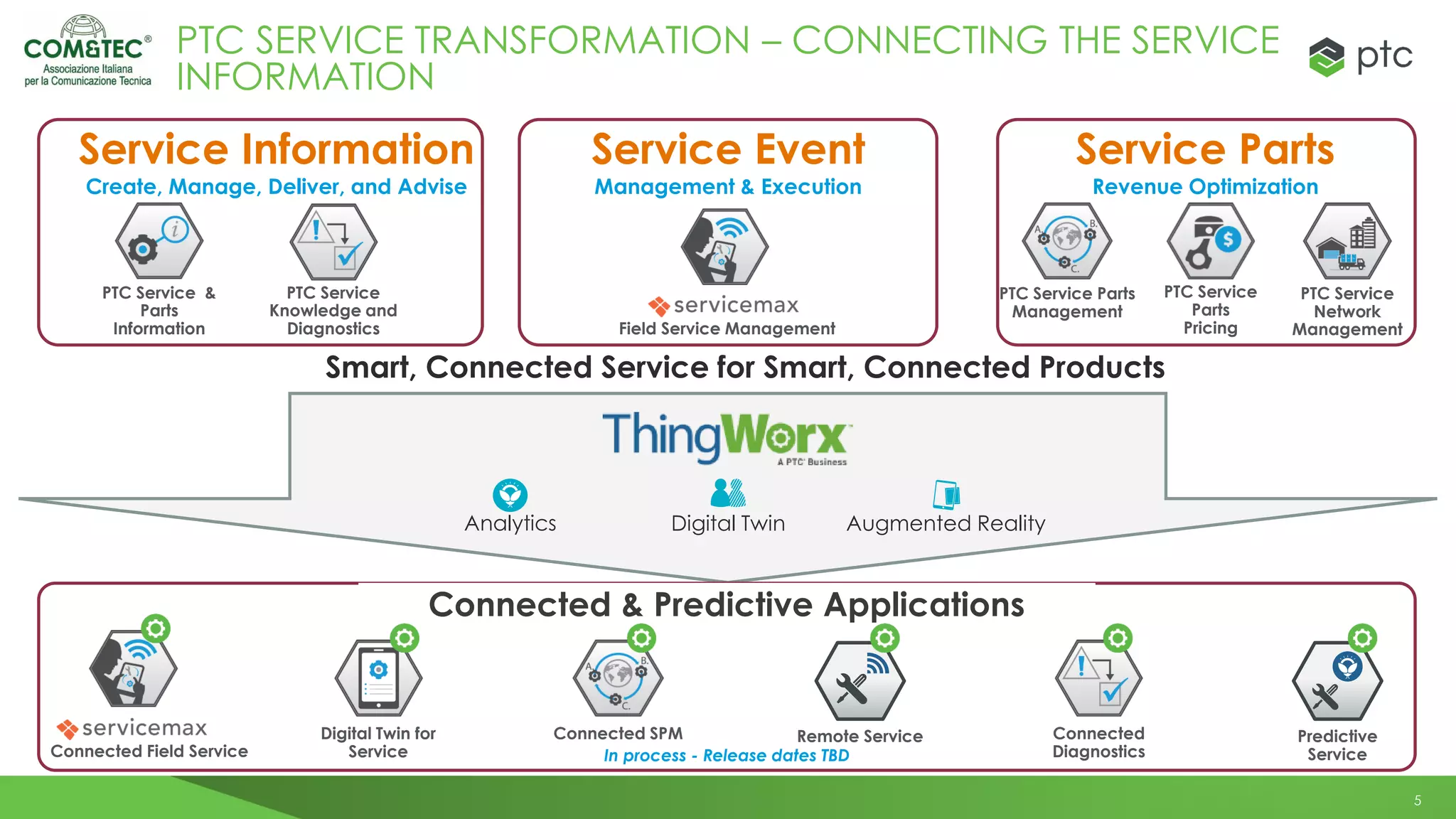

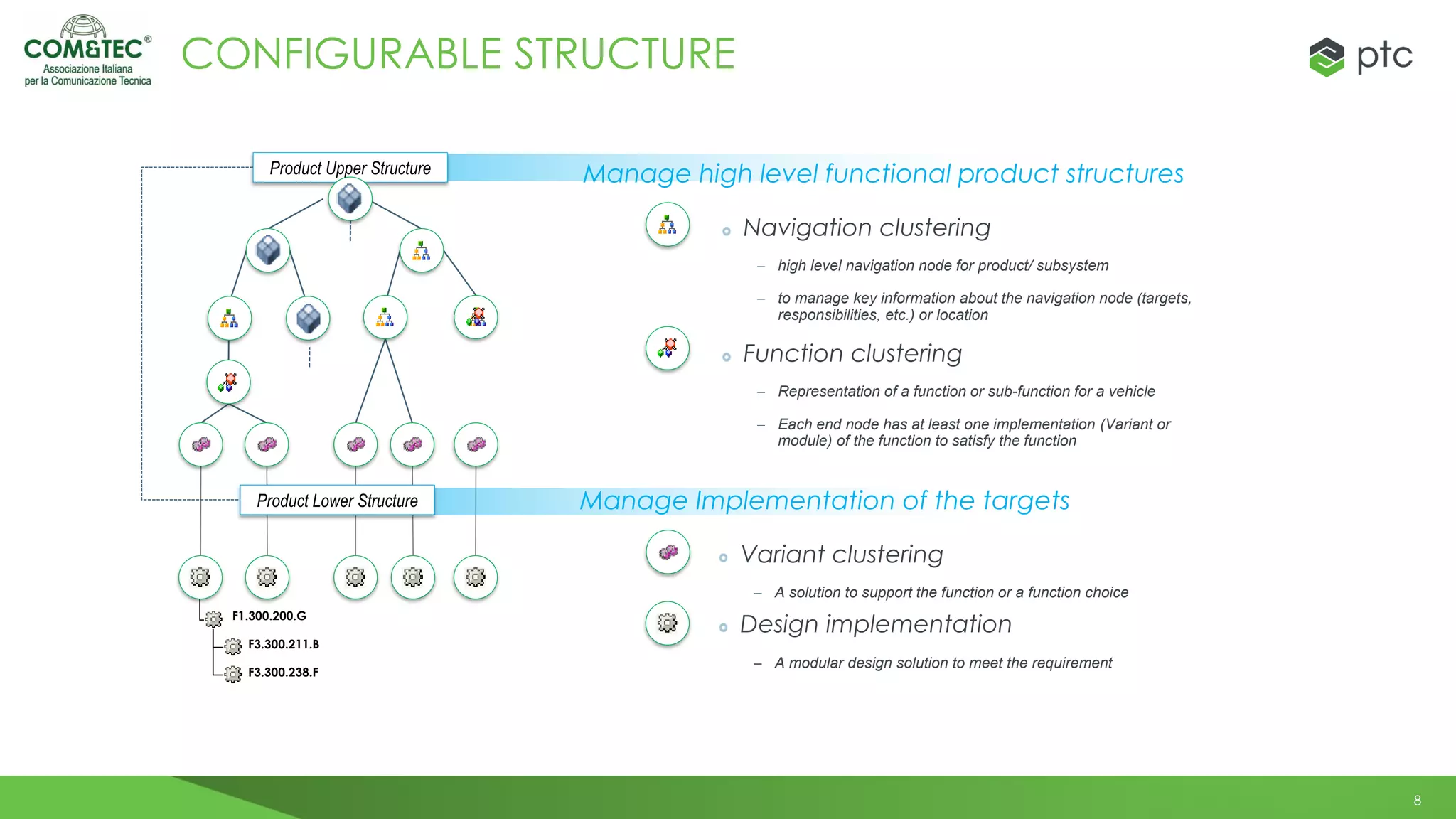

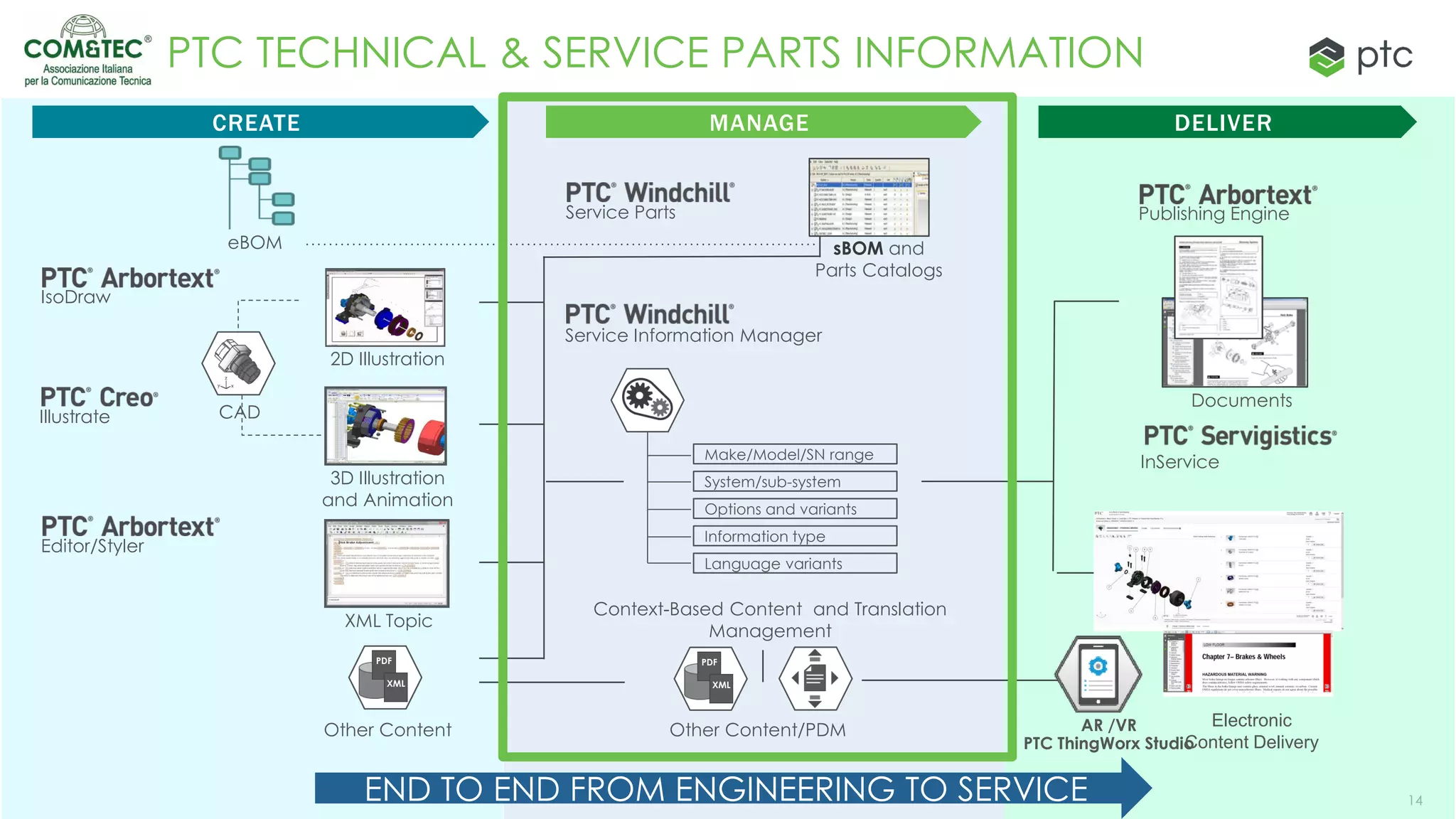

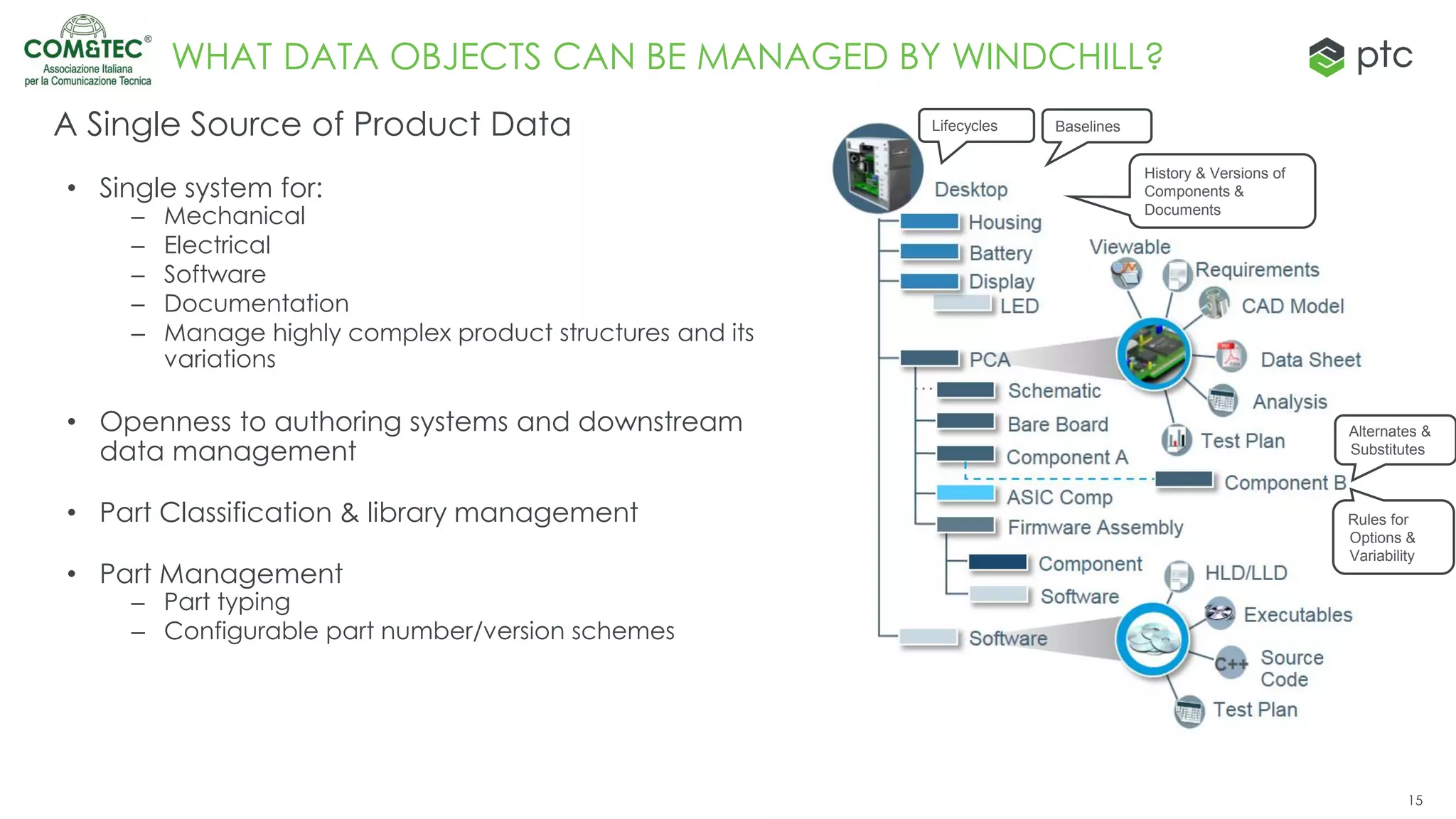

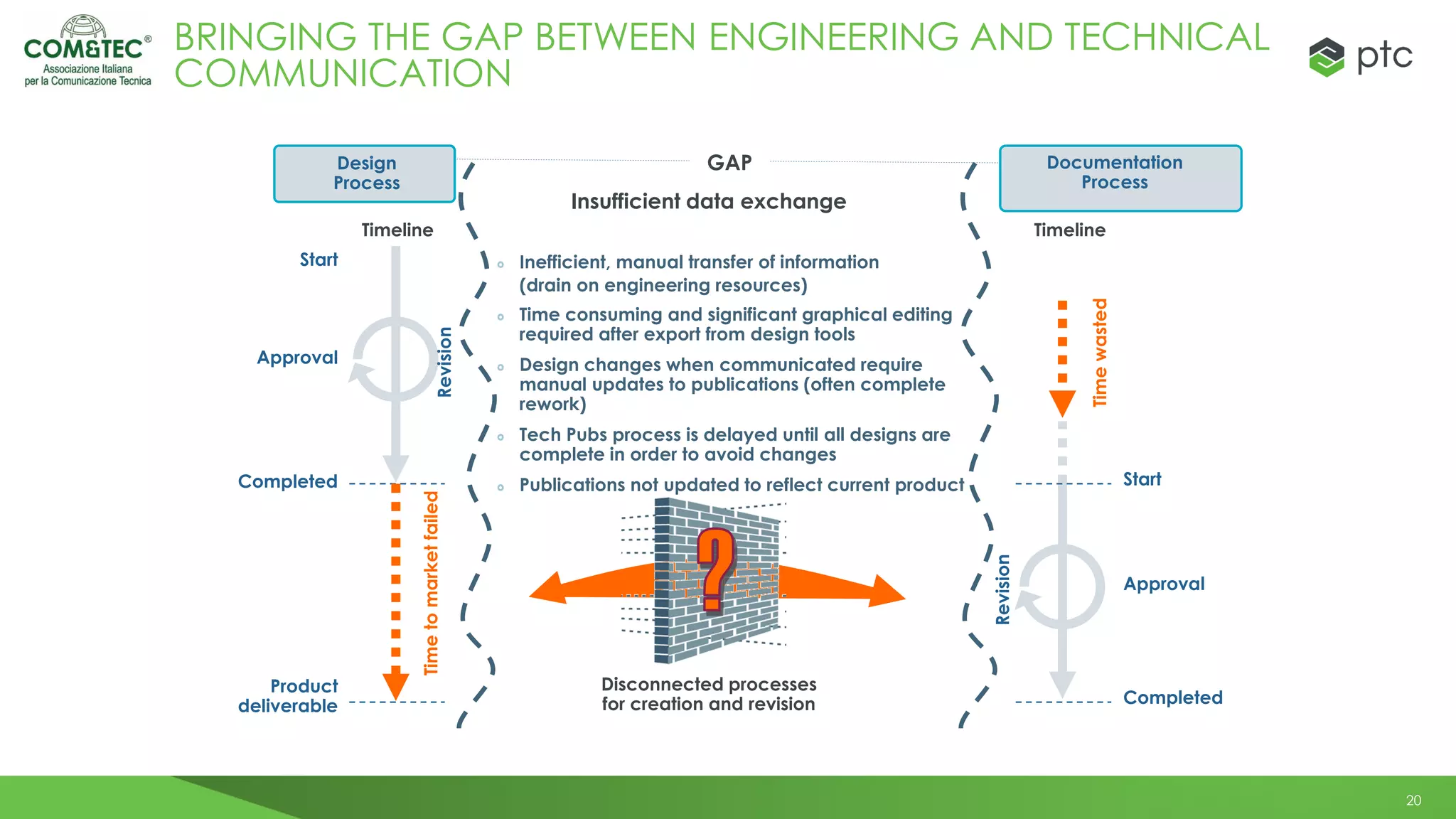

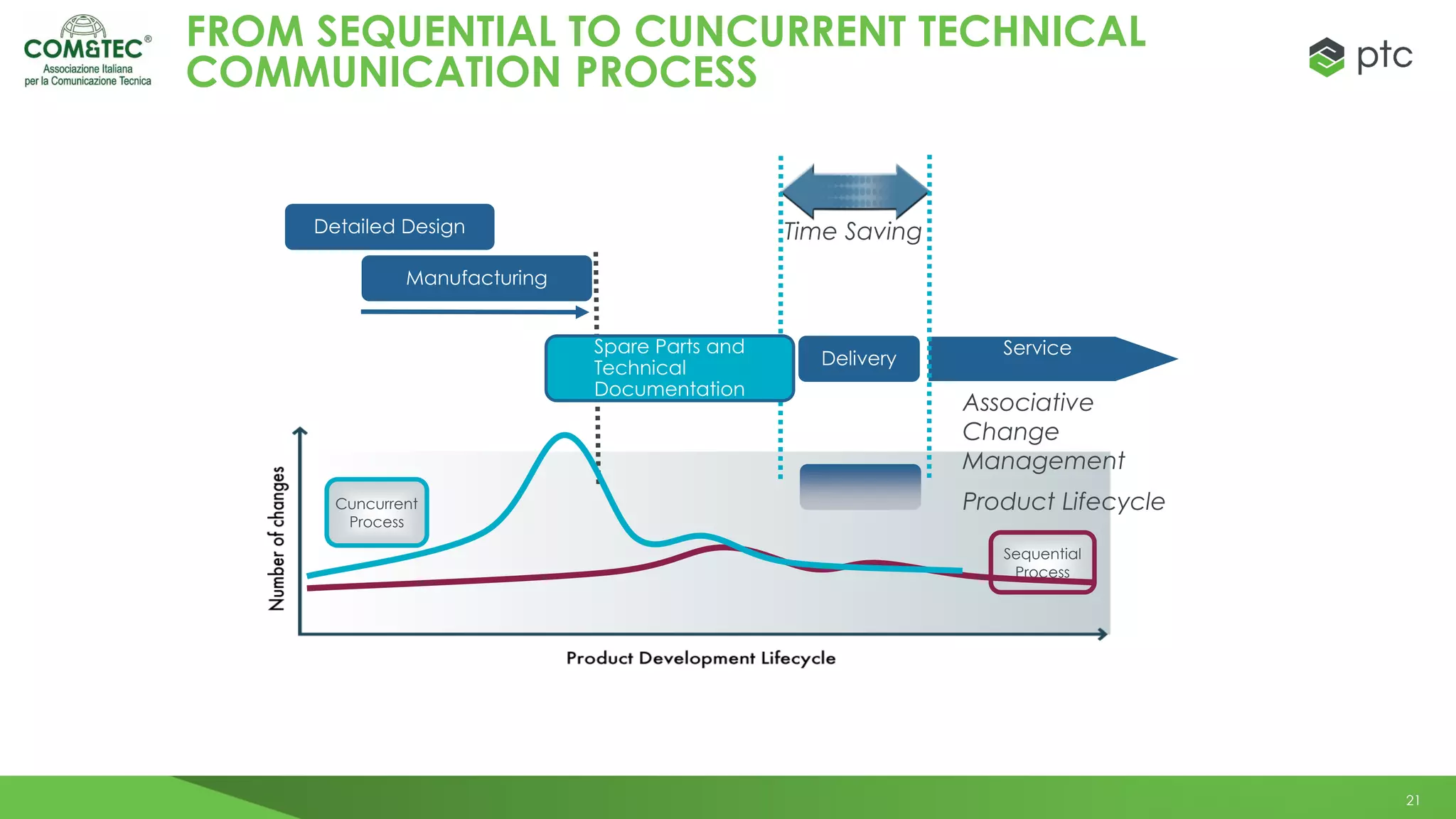

The document discusses PTC's integrated approach for managing technical documentation and service information for configure-to-order products. It highlights challenges with technical documentation timelines, accessing service information from different systems, and documentation not reflecting product configurations. The solution presented is PTC's Service and Parts Information solutions which provide an end-to-end single system for managing product structures, documentation, illustrations from CAD, and delivering technical content. Benefits include increasing service efficiency and profitability through improved access to up-to-date service information.