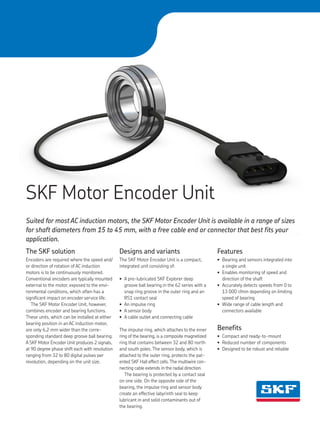

The SKF Motor Encoder Unit combines an encoder and bearing in a single integrated unit. It is installed in AC induction motors to monitor shaft speed and direction. It produces digital pulses that indicate speed ranging from 32 to 80 pulses per revolution depending on the unit size. The unit consists of a bearing, impulse ring, sensor body, cable, and seal components. It is compact at only 6.2mm wider than the bearing and suitable for shaft diameters from 15 to 45mm. Benefits include a reduced number of components, compact size, and reliable monitoring of motor speed and direction.