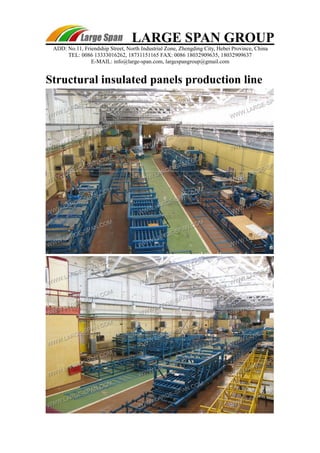

This document describes a structural insulated panels production line consisting of 6 machines:

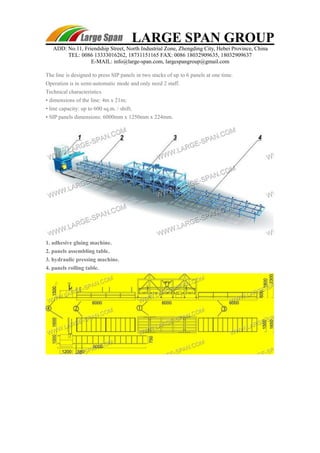

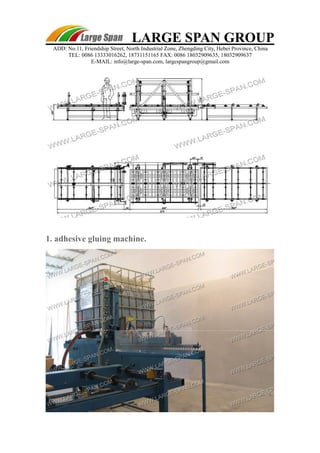

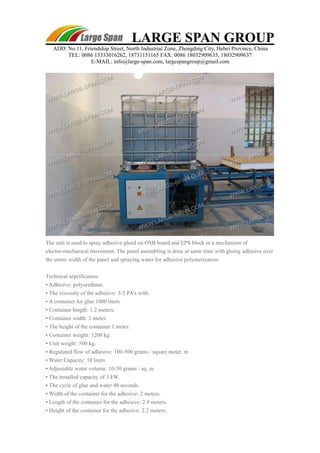

1) An adhesive gluing machine that applies polyurethane adhesive to OSB boards and EPS blocks.

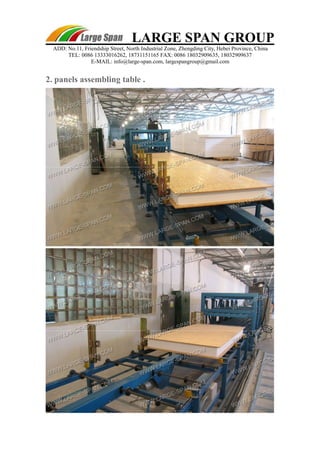

2) A panels assembling table where OSB, EPS, and OSB layers are stacked and fed into the hydraulic press.

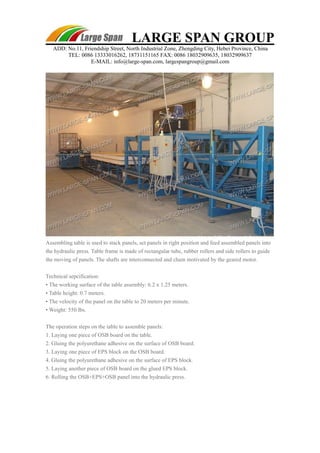

3) A hydraulic pressing machine that compresses the assembled panels to cure the adhesive bond.

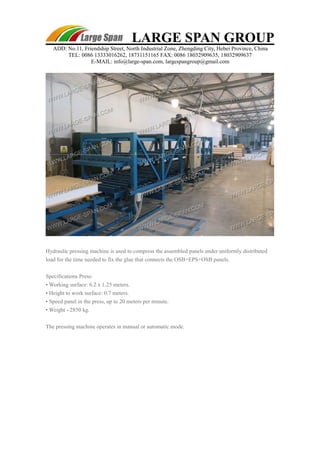

4) A panels rolling table that unloads the cured panels from the press.

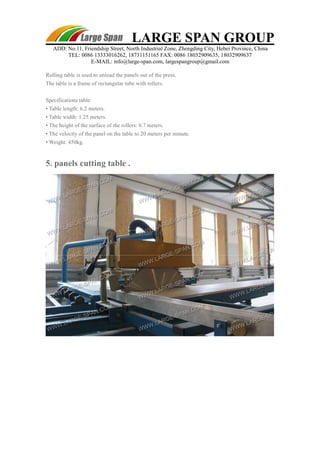

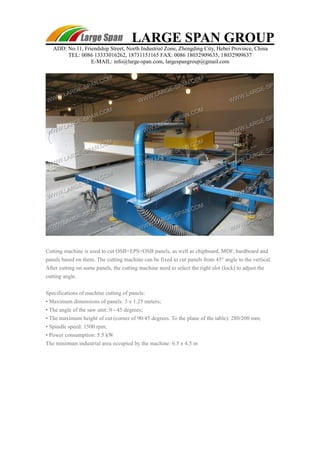

5) A panels cutting table that cuts the finished panels.

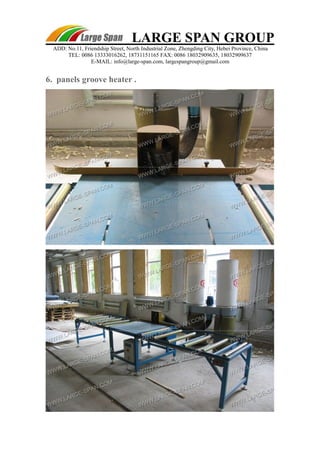

6) A panels groove heater machine that forms grooves in the panels.