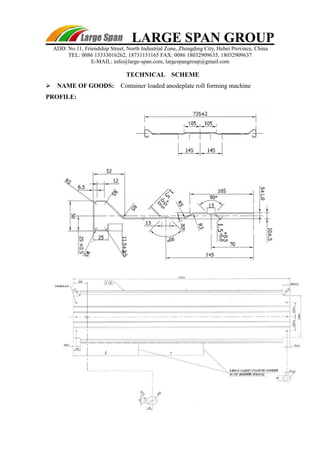

The document provides detailed specifications and information regarding a container-loaded anode plate roll forming machine offered by Large Span Group, including its features, technical data, and operational capabilities. The machine is constructed with various high-quality components from established brands, has a maximum forming speed of 15-20 meters/min, and a whole life warranty for certain parts. It also includes a quotation for purchase, payment terms, installation costs, and other operational details necessary for prospective buyers.