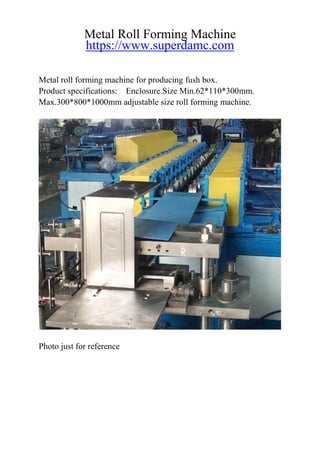

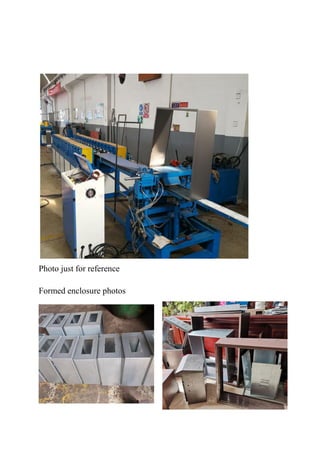

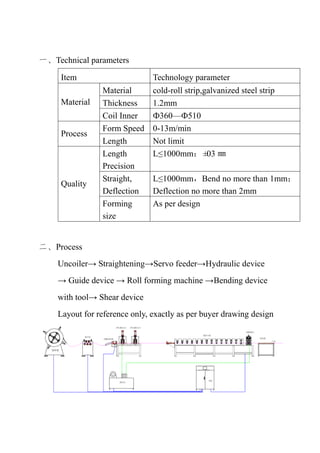

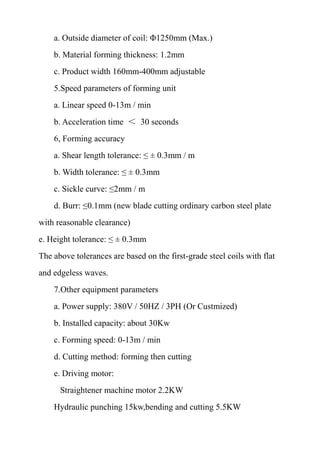

The document details a metal roll forming machine designed for producing distribution boxes, with adjustable size specifications ranging from 62x110x300mm to 300x800x1000mm. It outlines technical parameters, including material specifications, production speed (0-13m/min), and forming accuracy, detailing the production process from uncoiling to forming and bending. Additionally, it includes information on equipment configuration, control systems, and after-sales service provided by the supplier.