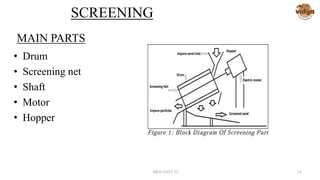

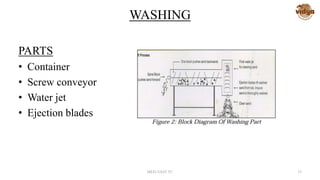

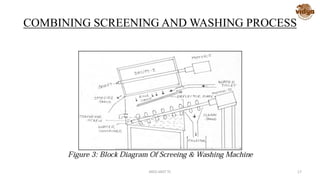

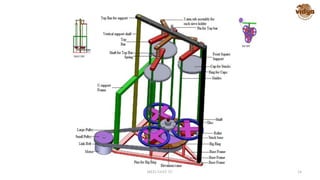

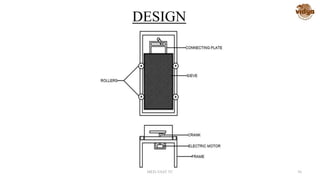

The document discusses the design and function of sand screening machines, emphasizing their importance in industrial applications where processed sand is required. It details various types of sieving machines, from manual to motor-driven, designed to efficiently separate sand by size while reducing labor and costs. Additionally, the document outlines the construction, operation principles, and objectives of a new portable sieving machine to enhance productivity in construction and material processing.