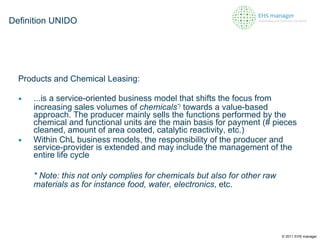

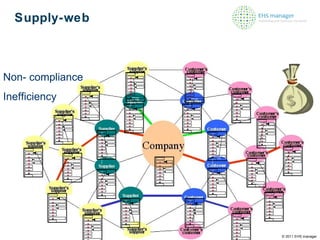

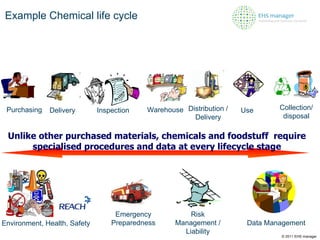

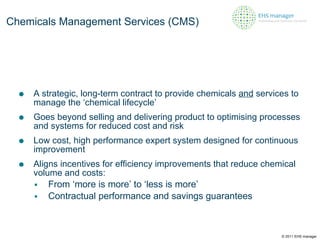

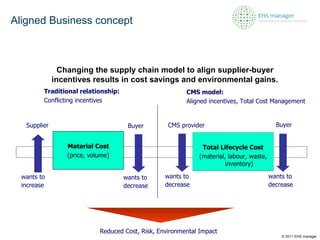

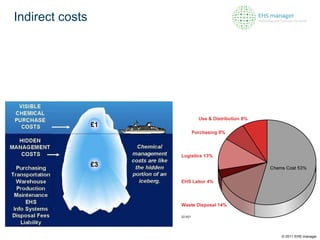

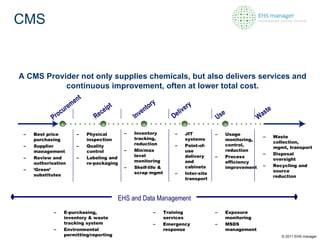

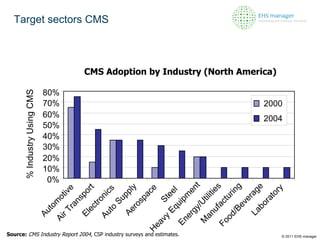

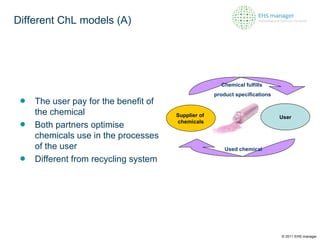

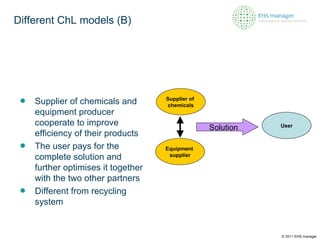

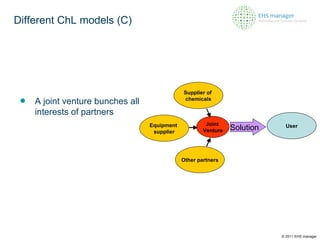

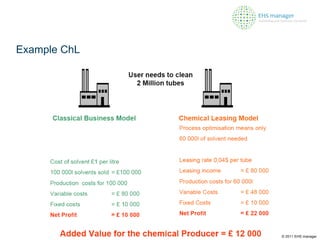

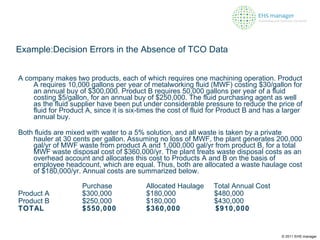

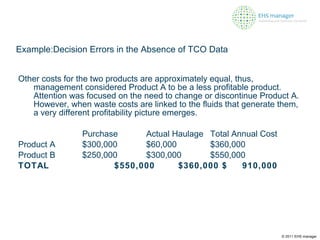

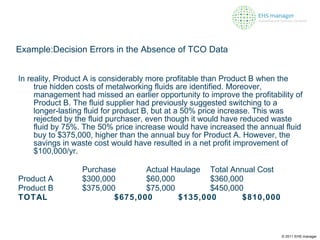

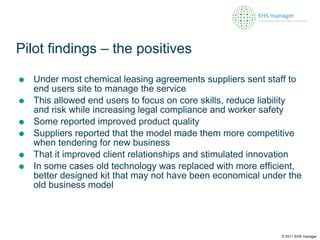

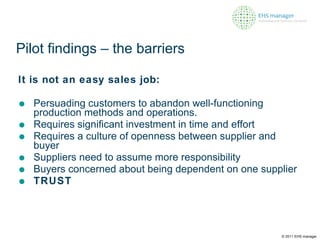

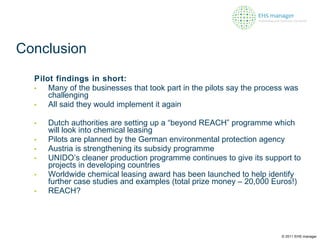

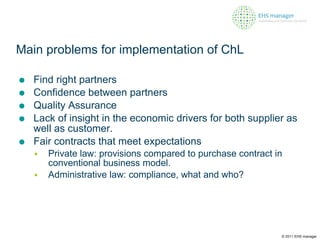

The document discusses a service-oriented business model known as chemical leasing, which emphasizes selling services rather than products, thereby managing the entire chemical lifecycle. This approach promotes cost savings and environmental gains through aligned incentives between suppliers and buyers. The document also highlights challenges and barriers in implementing chemical leasing, along with pilot findings from various industries and regions.

![Products and Chemical Leasing: Selling Services instead of Goods [email_address] © 2011 EHS manager](https://image.slidesharecdn.com/servicesinsteadofgoods-12941827125621-phpapp01/85/Services-Instead-Of-Goods-1-320.jpg)

![Interested? EHS manager can provide you with these services! [email_address] www.ehsmanager.nl Tel. +31 (0)6 8100 0708 Florimont 2 (Slot Haverleij) 5221 LX ‘s-Hertogenbosch © 2011 EHS manager](https://image.slidesharecdn.com/servicesinsteadofgoods-12941827125621-phpapp01/85/Services-Instead-Of-Goods-31-320.jpg)