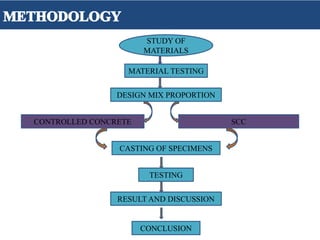

- The study aimed to determine the bond strength and chloride permeability of self-compacting concrete (SCC) compared to conventional concrete (CC).

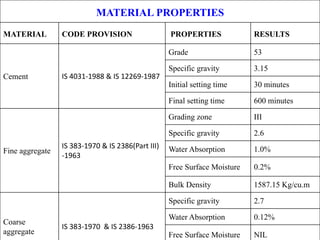

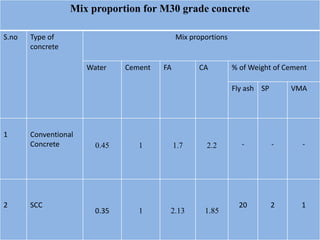

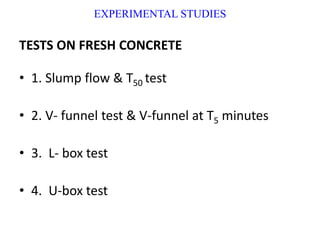

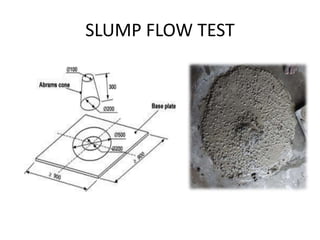

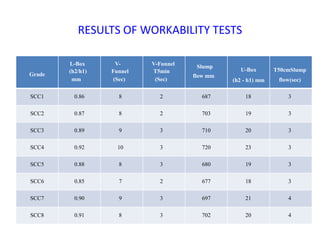

- Materials were tested to determine properties and optimize an SCC mix with 20% fly ash replacement. Workability tests established acceptable SCC mixes.

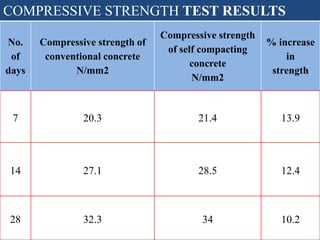

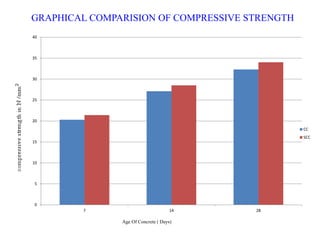

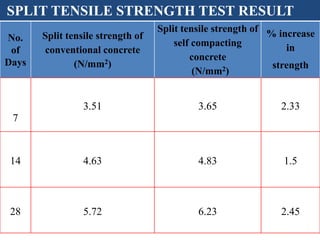

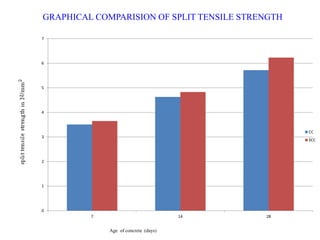

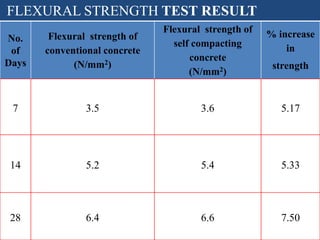

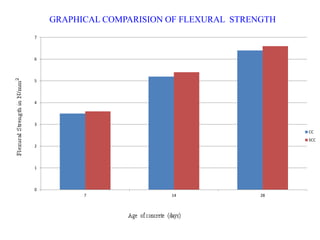

- Mechanical properties like compressive and splitting tensile strength were found to be higher for SCC compared to CC at curing ages of 7, 14, and 28 days.

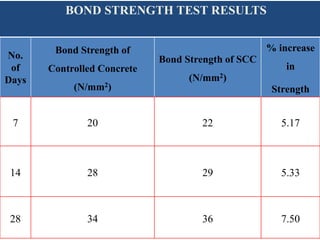

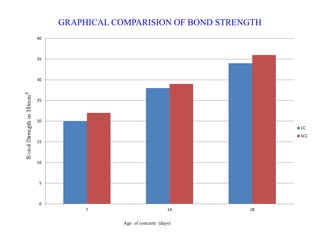

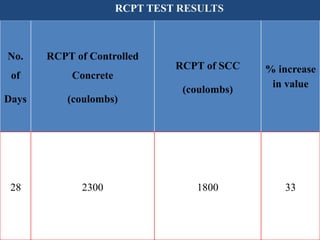

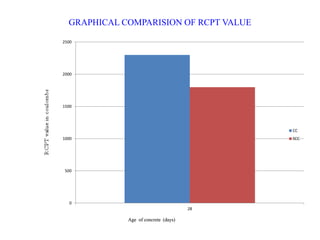

- Bond strength was evaluated through pullout tests and chloride permeability through rapid chloride permeability tests (RCPT), with results of SCC and CC compared.