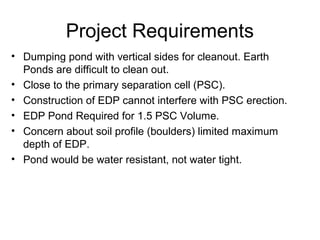

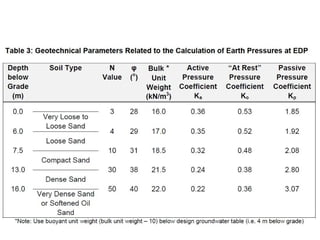

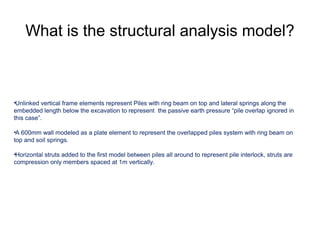

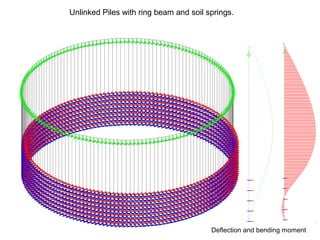

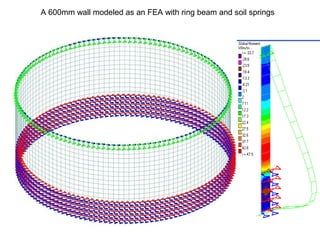

The document summarizes the design of a secant pile wall for an emergency dump pond (EDP). Key aspects include:

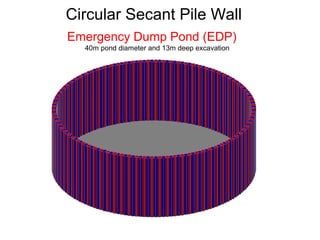

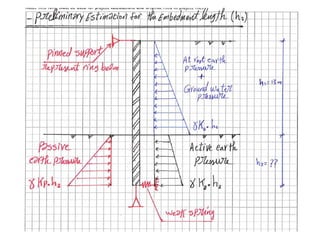

- The EDP requires a 40m diameter pond that is 13m deep for storage capacity.

- A secant pile wall was selected to provide vertical sides for cleaning, be close to other structures, and withstand soil conditions including boulders.

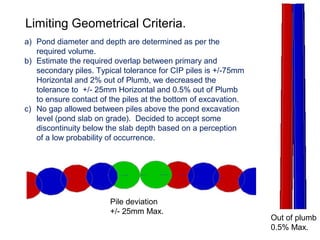

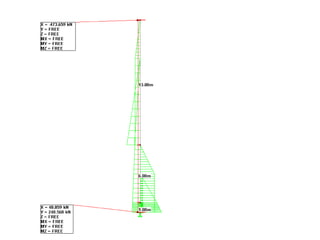

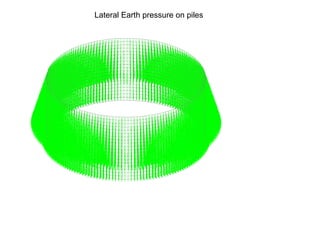

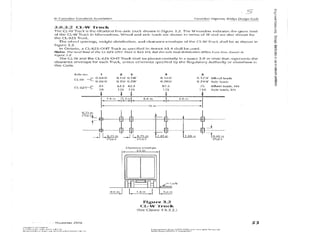

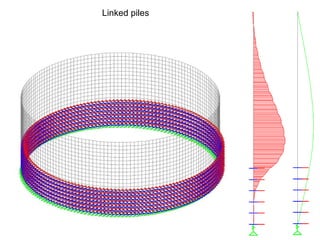

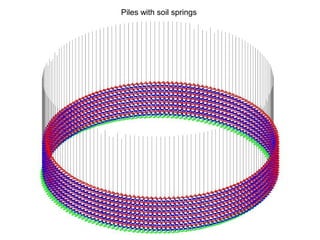

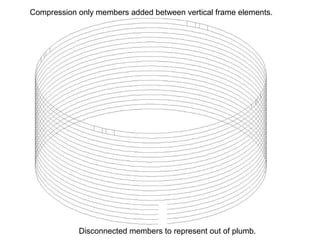

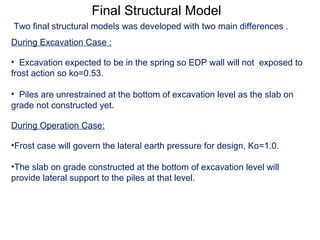

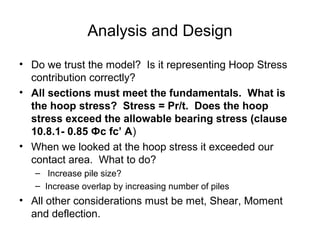

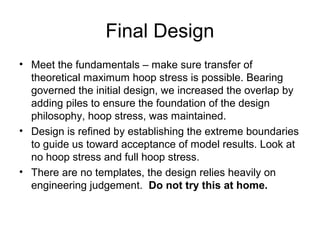

- The design considered geometric constraints, loading conditions, structural analysis models, and refined the pile size and spacing to ensure hoop stresses did not exceed allowable values.

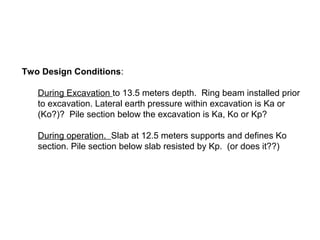

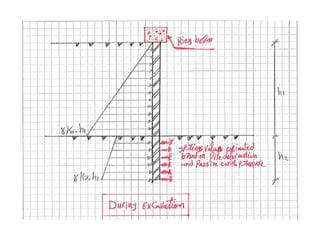

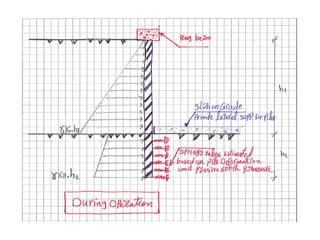

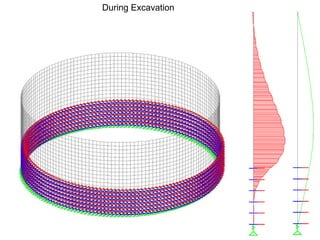

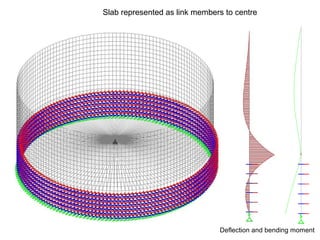

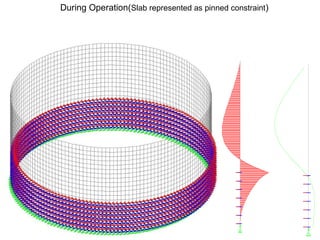

- Two design conditions were analyzed - during excavation and after the pond was in operation with a slab installed.

- Through analysis and engineering judgement, the final design met