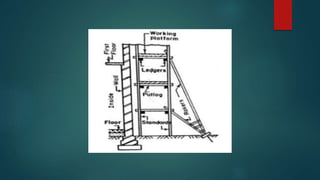

Scaffolding is a temporary structure used to support workers and materials during construction projects. There are several types of scaffolding that are used depending on the type of construction work. Single scaffolding consists of standards, ledgers, and putlogs used for brick masonry. Double scaffolding uses two parallel frames for stone masonry work. Cantilever scaffolding supports standards through holes in walls. Suspended scaffolding suspends working platforms from roofs. Trestle scaffolding supports platforms on movable tripods for indoor work. Steel scaffolding uses steel tubes and fittings for strength and flexibility. Patented scaffolding uses ready-made steel components with adjustable platforms.