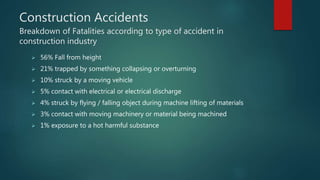

The document outlines comprehensive safety measures and protocols for construction sites, focusing on various hazards such as falls, electrical risks, and excavation dangers. It highlights the importance of adhering to safety regulations, conducting thorough risk assessments, and ensuring proper equipment and training for workers. Additionally, the text emphasizes the role of human behavior in maintaining a safe work environment and calls for continuous monitoring and safety awareness initiatives.