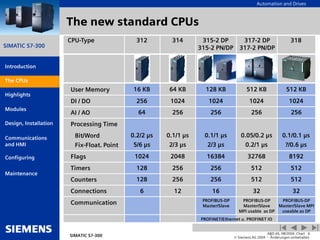

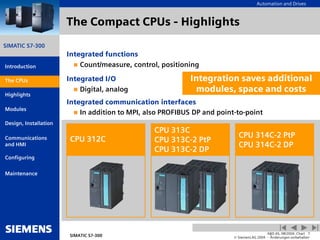

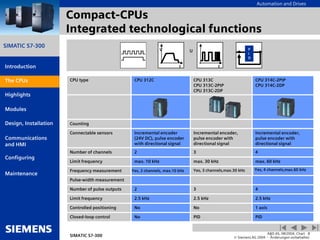

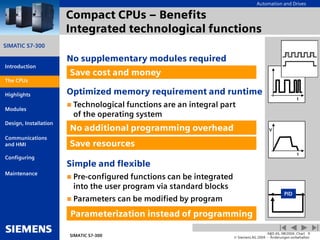

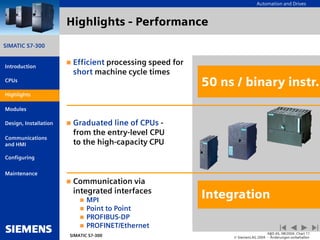

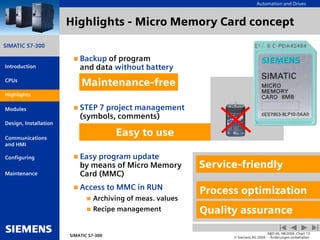

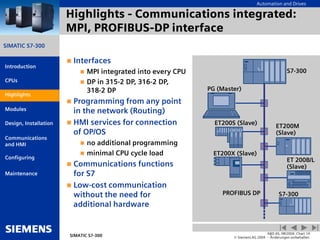

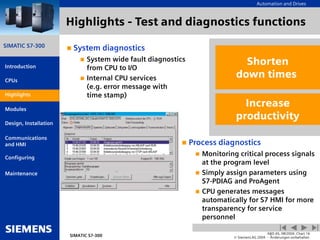

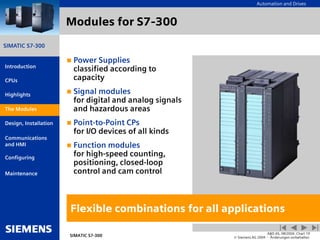

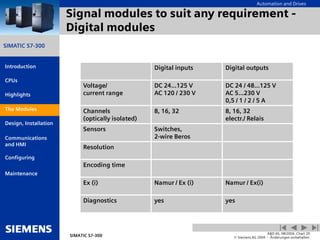

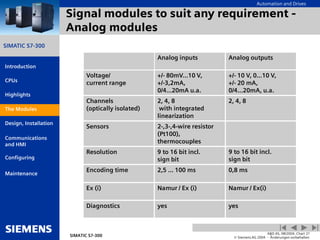

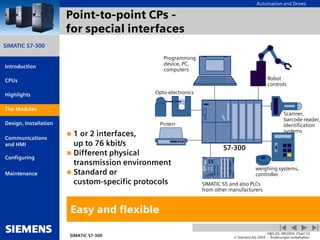

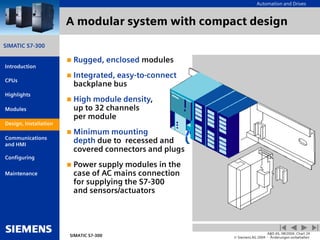

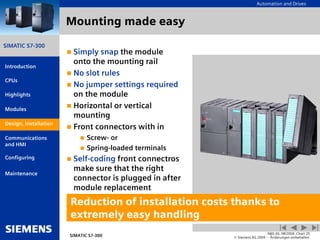

The document provides detailed information on the Siemens Simatic S7-300, a versatile programmable logic controller (PLC) designed for production engineering. It highlights the various CPU types, their specifications, integrated functionalities, and the benefits of compact design, modular construction, and efficient communication capabilities. The document emphasizes the system's adaptability for diverse applications and its focus on reducing engineering costs and optimizing machine performance.