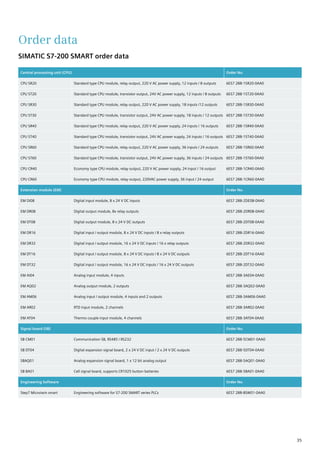

Siemens' SIMATIC S7-200 SMART PLC offers an affordable and flexible automation solution for developing markets. It provides a range of CPU modules with integrated I/O and communication ports. Additional I/O and communication can be added via cost-effective signal boards. The PLC uses a high-speed processor and user-friendly software to provide powerful motion control, networking, and programming capabilities despite its low cost. It can be integrated with other Siemens products to create complete automation solutions for applications like packaging machines.