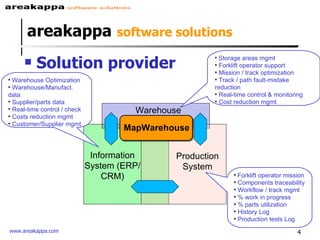

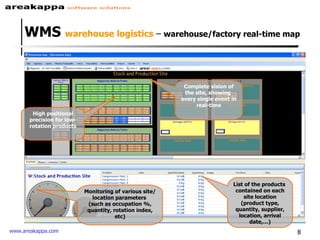

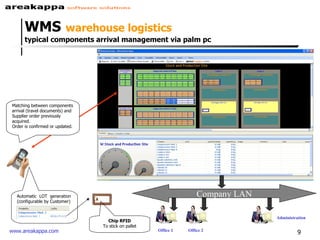

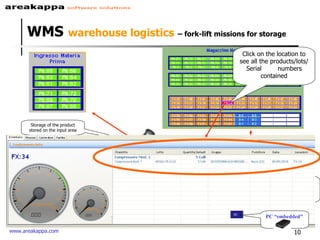

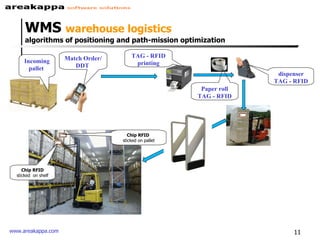

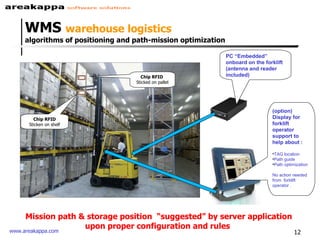

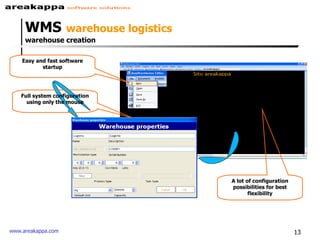

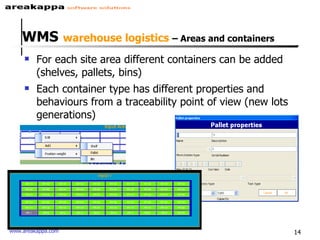

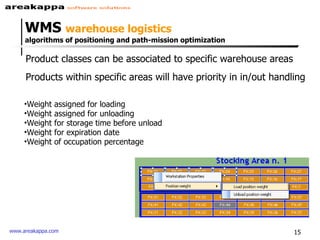

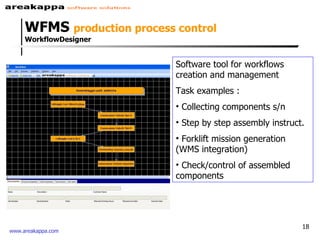

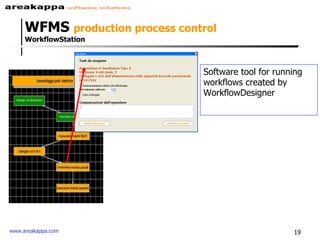

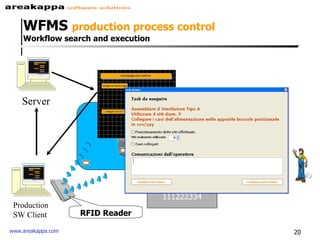

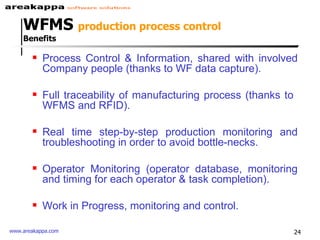

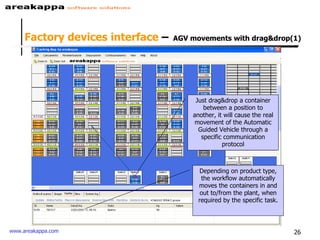

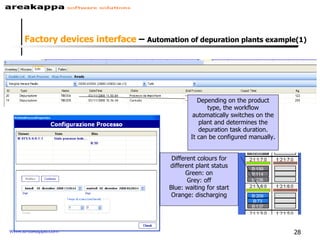

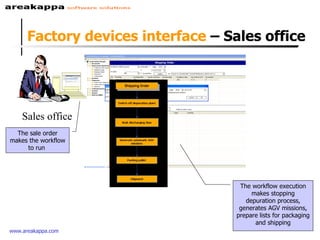

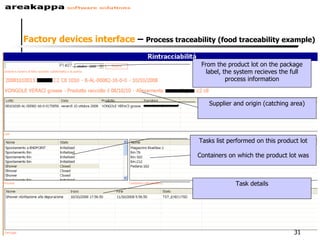

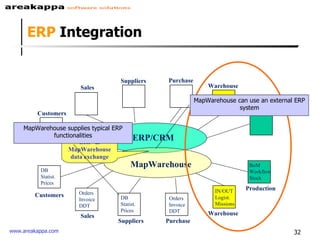

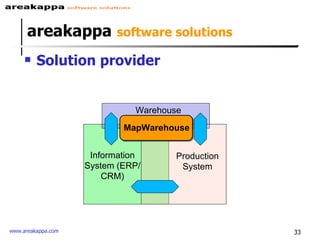

Map Warehouse is an integrated software solution developed by Areakappa that covers warehouse management, product traceability, and manufacturing process management. It includes modules for warehouse management (WMS), workflow management (WFMS), integration with factory devices, and integration with ERP systems. The solution aims to improve information management and data exchange between different IT systems used in warehouses and manufacturing. It provides benefits such as reduced errors, full product traceability, and real-time process monitoring.

![Contacts Web: www.areakappa.com Mail: [email_address]](https://image.slidesharecdn.com/mapwarehouse-12791097609189-phpapp02/85/MapWarehouse-34-320.jpg)