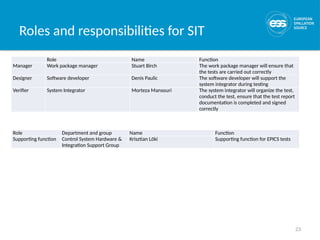

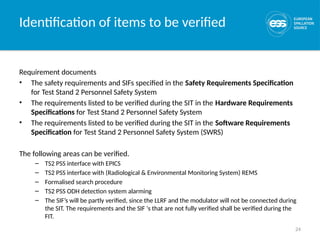

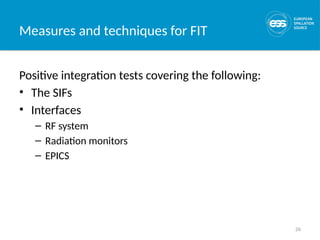

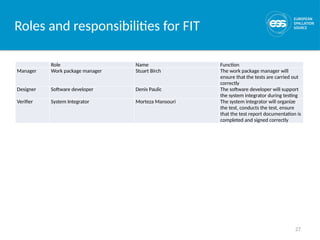

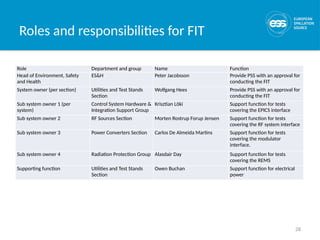

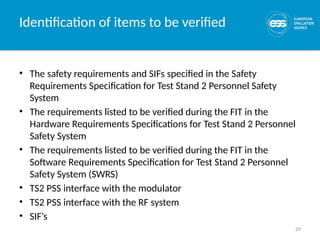

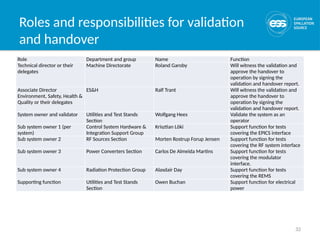

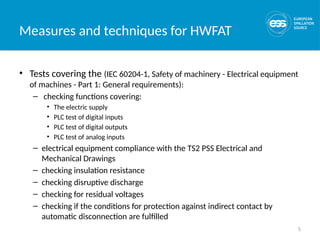

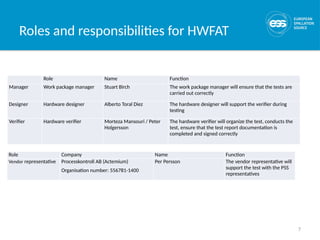

The document outlines the verification and validation process for the Test Stand 2 Personnel Safety System, detailing the Factory Acceptance Test (FAT), Software Pre-FAT, Site Acceptance Test (SAT), System Integration Test (SIT), Final Integration Test (FIT), and Validation and Handover procedures. It describes specific measures, responsibilities, and documentation needed at each stage to ensure compliance with safety and operational requirements. The roles of various team members and vendors involved in the testing process are clearly defined throughout the document.

![18

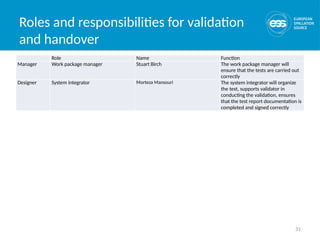

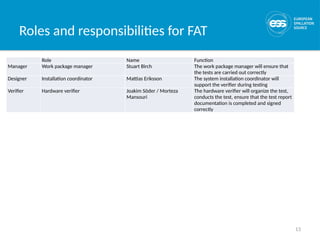

Roles and responsibilities for pre-FAT

Role Name Function

Manager Work package manager Stuart Birch The work package manager will ensure that the

tests are carried out correctly

Designer Software developer Denis Paulic The designer will support the verifier during

testing

Verifier Software verifier Sam Crossland The software verifier will organize the test,

ensure that the test specification is carried out,

ensure that the documentation is completed

and signed correctly

Reviewer Software developer Martin Carroll / Johannes

Gustafsson

The reviewer will conduct a code review, for

details see the Verification and Validation Plan

for Personnel Safety Systems [3]](https://image.slidesharecdn.com/vvforts2pss-241107221249-76fdfda6/85/REVISION-DE-PROCESOS-BAJO-NORMA-EUROPEA-BASICAS-18-320.jpg)