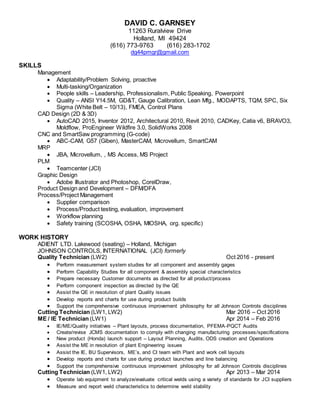

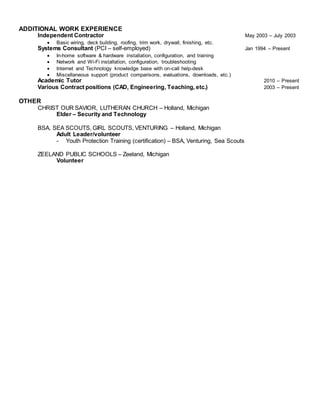

David C. Garnsey has over 30 years of experience in management, CAD design, CNC programming, quality control, and product design. He currently works as a Quality Technician at Adient Ltd. in Holland, Michigan. Garnsey has a diverse skill set including CAD, Lean manufacturing techniques, and quality certifications. He holds degrees from Western Michigan University and University of Phoenix.