The document describes a proposed design for a stair-climbing wheelchair. It includes mechanical components like a custom chassis, axles connected to wheels via sprockets and gears to be powered by DC motors. Electrical components include motor drivers and sensors like an accelerometer and ultrasonic sensors. The wheelchair is controlled by a microcontroller board that processes inputs from a joystick and sensors. It controls motors and servos to enable climbing stairs and maintain stability. The design aims to allow physically challenged users to navigate difficult terrains like stairs with ease and safety.

![Shashank Shekhar Sahoo et al. Int. Journal of Engineering Research and Applications ww.ijera.com

ISSN: 2248-9622, Vol. 6, Issue 3, (Part - 1) March 2016, pp.74-79

www.ijera.com 74|P a g e

Research on Optimization, Dynamics and Stability of Stair-

climbing Wheelchair

Shashank Shekhar Sahoo*, Himank Kinkar**

*(Department of Powertrain, Magneti Marelli India Pvt. Ltd., Gurgaon-51

** (Department of Powertrain, Magneti Marelli India Pvt. Ltd., Gurgaon-51

ABSTRACT

Since the invention of the wheel, man has always sought to reduce effort to get things done easily. Ultimately, it

has resulted in the invention of the Robot, an Engineering Marvel. Up until now, the major factor that hampers

widespread usage of robots is locomotion and maneuverability. They are not fit enough to conform even to the

most commonplace terrain such as stairs. To overcome this, we are proposing a stair climbing wheelchair robot

that looks a lot like a normal wheelchair but with additional stair-climbing functionality to adjust itself

according to the height of the step The primarily goal of the prescribed manuscript herewith is to analyze the

functional requirements, optimization methods, dynamics and stability during a tracked robotic wheelchair’s

climbing of stairs mechanism. At first, the mechanical structure of the wheelchair is designed and the hardware

composition of its full control system is devised. Secondly, based on the analysis of its stairs‐climbing process,

the dynamical model of stairs‐climbing is established by using the classical mechanics method. Next, through

simulation and experiments, the effectiveness of the dynamical model, its stability evaluation and performance

parameters is verified. Such procedures will help in establishing a strong fundamental foundation steps to design

and develop a standalone semi-autonomous wheelchair that will help and enable a physically challenged person

by leg to climb difficult terrains like staircase and speed-breakers with ease and comfort. This design

encompasses Renesas’s Arduino compatible GR-KAEDE boards, servo motors, high torque DC motors and

various peripheral devices as incorporated in design diagram. We have also extended the application of

wheelchair by integrating collision avoidance mechanism.

Keywords - Robot, Arduino, Climbing Robot, wheelchair, GR-KAEDE boards

I. INTRODUCTION

Modern wheelchairs are available with various

accessories, such as anti-tip bars or wheels, safety

belts, adjustable backrests, tilt and/or recline

features, extra support for limbs or neck, mounts or

carrying devices for crutches, walkers or oxygen

tanks, drink holders, and clothing protectors [1].

Transport wheelchairs are usually light, folding

chairs with four small wheels. These allow for a

broader spectrum of movement. However, very few

have experimented to enable a wheelchair with

stair-climbing maneuverability.

During stairs-climbing, the wheelchair begins by

touching the first step of the stairs through its front

track while its two-sided driving motors

simultaneously push the driving wheels and the

whole wheelchair forward, up to the first step and

then the second step, whereby the entire robot

leaves the ground and completely climbs upwards

on the stairs. The whole process may be divided

into six stages, as shown in Figure 1: a) touch the

first step; b) climb up the first step; c) touch the

second step; d) climb up the second step; e) leave

the ground and then ascend the stairs; (f) leave the

stairs and then access the ground. Here, touching

the step means the track near the robot’s front

approach angle climbing onto the step, while

climbing up the step means the bottom track of the

robot climbing onto the step [2].

Fig. 1

RESEARCH ARTICLE OPEN ACCESS](https://image.slidesharecdn.com/m6301074079-160728061528/75/Research-on-Optimization-Dynamics-and-Stability-of-Stairclimbing-Wheelchair-1-2048.jpg)

![Shashank Shekhar Sahoo et al. Int. Journal of Engineering Research and Applications ww.ijera.com

ISSN: 2248-9622, Vol. 6, Issue 3, (Part - 1) March 2016, pp.74-79

www.ijera.com 76|P a g e

pulses (50 in one second) is required to be passed

to the servo to sustain a particular angular position.

When the servo receives a pulse, it can retain the

corresponding angular position for next 20ms, So, a

pulse in every 20ms time frame must be fed to the

servo.

1.2.4 3-AXIS LINEAR ACCELEROMETER

It will closely monitor the tilt of sitting platform

with respect to ground and will assist in

maintaining a perfect horizontal level as required to

keep the integrity of comfort and stability. The

ADXL335 is a small, thin, low power, complete 3-

axis accelerometer with signal conditioned voltage

outputs. The product measures acceleration with a

minimum full-scale range of ±3 g. It can measure

the static acceleration of gravity in tilt-sensing

applications, as well as dynamic acceleration

resulting from motion, shock, or vibration.

1.2.5 POWER SOURCE

A single 12V rechargeable DC battery to supply

enough current to drive huge inductive loads of

high torque motors and related accessories.

1.2.6 COLLISION AVOIDANCE SENSOR (UV

TRANSCEIVERS)

The sensors will check, detect and inform the

microcontroller about any imminent collision

possible due to any nearby object. The HC-SR04

ultrasonic sensor uses sonar to determine distance

to an object like bats or dolphins do. It offers

excellent non-contact range detection with high

accuracy and stable readings in an easy-to-use

package. From 2cm to 400 cm or 1” to 13 feet. It’s

operation is not affected by sunlight or black

material like Sharp rangefinders are (although

acoustically soft materials like cloth can be difficult

to detect). It comes complete with ultrasonic

transmitter and receiver module.

1.2.7 JOY-STICK

To accept directional instructions from the user.

The 2-Axis Joystick is used to add analog input to

our project. The 2-Axis Joystick contains two

independent potentiometers (one per axis) that can

be used as dual adjustable voltage dividers,

providing 2-Axis analog input in a control stick

form. The modular form-factor allows one to plug

the 2-Axis Joystick directly into a breadboard for

easy prototyping. The 2-Axis Joystick includes

spring auto return to center and a comfortable cup-

type knob which gives the feel of a thumb-stick.

1.2.8 GEARED DC MOTORS

To drive the wheels interlocked with conveyer

belts. These are very high torque powerful motors

with the capability to drive the entire system with

ease and activates upon receiving user input from

joystick.

Other active and passive electronic components

like resistors, LEDs, transistors etc.

II. WORKING PRINCIPLE

The customized wheelchair will take directional

instructions as input from driver and will drive the

wheels accordingly as per processed logic. In the

event of staircase climbing, the driver has to orient

the wheelchair with backside facing the stairs.

Then continue normal traversing until the first step

is covered [2]. In order to maintain stability, the

servo motors will then align the sitting platform

horizontal to ground by rotating through an angle

alpha(α). While undertaking this process, 3 axis-

Accelerometer will continuously monitor the level

change of platform with respect to gravity and will

help in achieving accuracy and stability. With this

configuration, one can climb the further steps with

ease. When the distance to potential colliding

object measured by ultrasonic sensors violate the

threshold preset conditions, an alert will be

displayed on LCD to stop the wheelchair

automatically as per Mode 0 operation and will

wait for next user’s instruction to switch into Mode

1 to continue moving , keeping minimum distance

to detected object in mind.

III. SYSTEM DESIGN SPECIFICATION

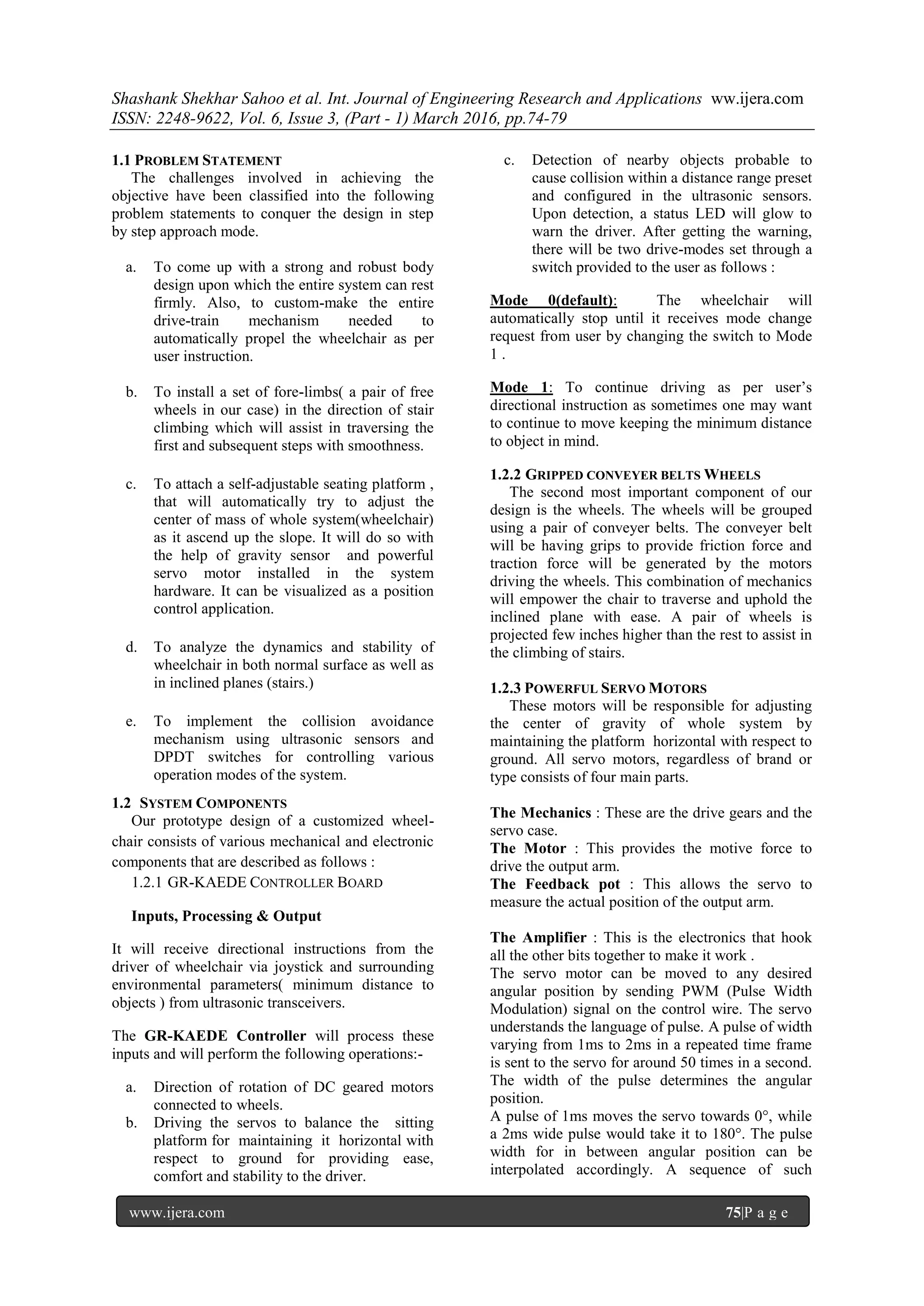

3.1 MECHANICAL

The chassis used in the wheelchair is an in-

house custom-made prototype that involves the

combination of an innovative axles, highly stable

metal body, bi-cycle sprocket with gear sets and

screw joints to fix them all together. The axles used

in the project are actually reverse-engineered

version of what we normally see in bicycle, where

a single pedal turn of larger diameter sprocket

results in multiple turns of smaller diameter

sprocket connected to the rear wheels. Similarly,

here also we have mechanically coupled a pair of

wheels with similar axles and installed gear set on

it which will be propelled by high torque powerful

DC motors using driver and driven mechanism.

The sprocket of front and rear axles are coupled

mechanically using chain- links that are usually

found in bi-cycles, and these are customized and

adjusted to fit the design with zero tension and

torsion force. This mechanism is replicated on

other side as well taking into account the other pair

of wheels. The USP of this particular design is that

just by connecting a single high torque DC motor,

one can propel the entire one-half of the system.

So, technically speaking two motors are sufficient

enough in this design to propel the entire four-

wheel drive system with ease and comfort. Four

such combination consisting of sprocket, axle, axle

with gears and chains are formulated in such a

manner to provide high stability to the system [3].](https://image.slidesharecdn.com/m6301074079-160728061528/75/Research-on-Optimization-Dynamics-and-Stability-of-Stairclimbing-Wheelchair-3-2048.jpg)

![Shashank Shekhar Sahoo et al. Int. Journal of Engineering Research and Applications ww.ijera.com

ISSN: 2248-9622, Vol. 6, Issue 3, (Part - 1) March 2016, pp.74-79

www.ijera.com 78|P a g e

Fig. 5

IV. IMPLEMENTATION NOTE

It started with chassis design which is a

rectangular frame with compartments for wheel and

driving motors. Then the axle design, that has been

customized out of bi-cycle axles. It has been made

retro fit to accommodate gears and sprocket around

the opposite sides of rim. Four such units were

designed with sprockets on all the four and driving

gears on the rear wheels [4].

We needed to add additional pair of wheels to

enable the wheelchair to climb the stairs . For this a

separate pair of wheels were made to project out of

wheelchair body with marginal lift but in alignment

with other wheels. The main usage was to assist the

wheelchair to climb stair steps with ease. The next

step was to wrap around a set of two conveyer belts

encompassing wheels in phase and alignment.

Doing such made the wheel drive more robust and

it ensured proper movement of wheels in difficult

terrains without losing traction and control off the

road or stairs.

Later on, a stable light weight platform was

attached around the horn of the servo and was

mounted with the help of two center mast from the

central section of chassis. This platform is also

connected mechanically to accelerometer to detect

change in orientation of the platform and to make

the platform parallel to the ground.

As add-on in our custom designed wheelchair we

have also attached an ultrasonic sensor in the

façade of system to detect any nearby object which

might cause imminent collision.

During prototype testing it was observed that the

sprocket chain arrangement was creating a hurdle

while climbing the stairs as the radius of the wheels

chosen wasn’t providing sufficient edge clearance.

So, chain was removed.

All these modules were tested within their

constraints and in compliance with their

specification to meet the required objective over

various load conditions.

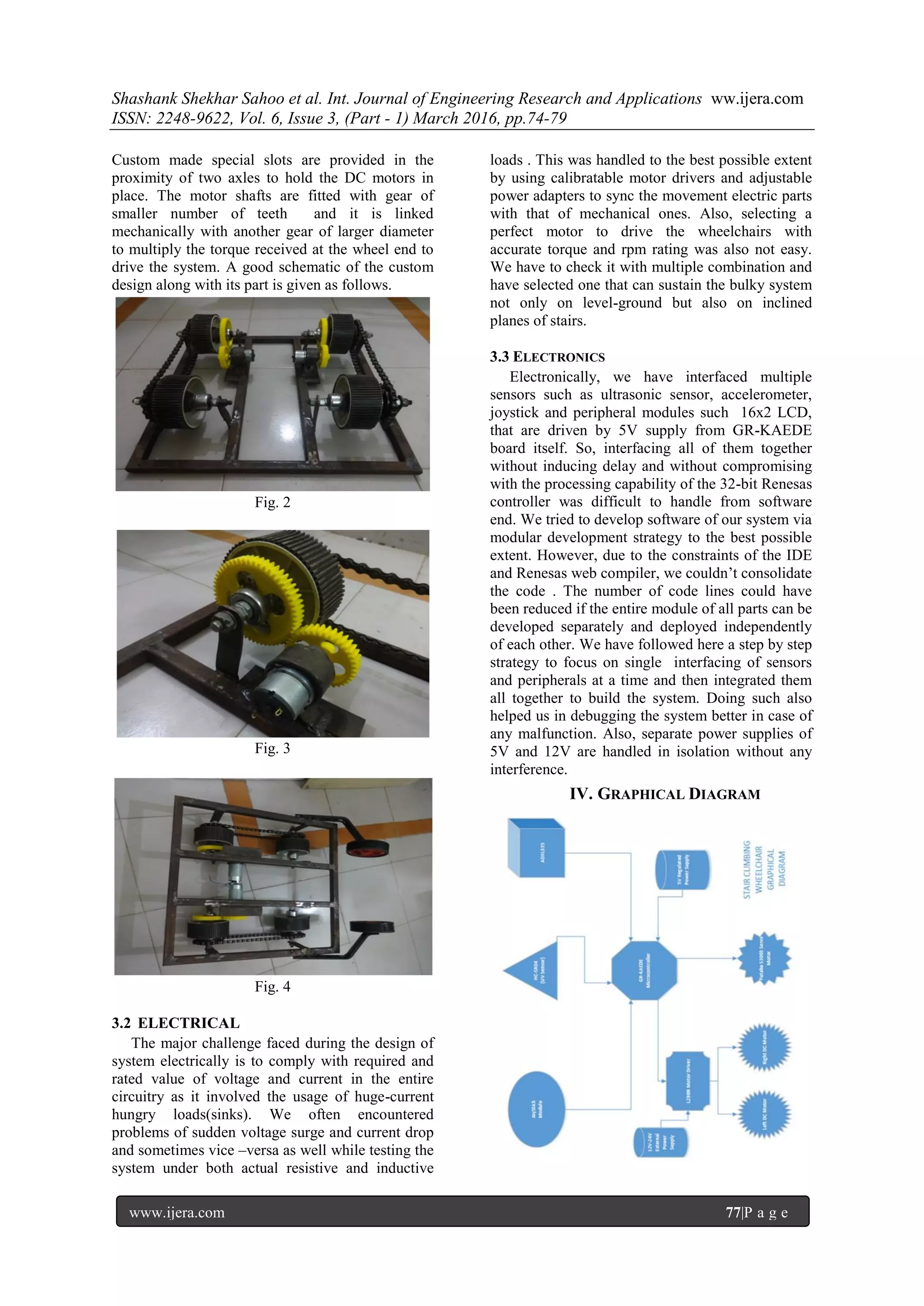

V. CIRCUIT DIAGRAM

Fig. 6

VI. SYSTEM TESTING, RESULTS &

DISCUSSION

The wheelchair system is developed in

compliance with modular development strategy.

So, it’s testing is also done in somewhat similar

manner. We have performed multiple unit – testing

of various system parts while they are under

development in order to ensure about the quality,

endurance, stability , robustness and integrity.

Some of the tests performed are as follows :-

a. Test to check proper fitting of wheel cut-set

with that of axle.

b. Test to inhibit back free-movement of

sprocket by welding of sprocket inner body

with that of axle.

c. Test to check and ascertain any relative

motion between gear cut-set and axle , that

might result as consequence of loose bond

between the two parties.

d. Test to ensure ground clearance and stability

of entire system while the installation of all

four wheels is done.

e. Test to observe the behavior of system in

terms of traction control, stability, driving

torque and custom manoeuvrability by just

installing the motors but not the conveyer

belts. Technically, we want to make it

traverse an inclined plane simulating the

same angle of inclination as that of stairs.

f. Next test was to fit the chain-links

encompassing both front and back sprocket

with no tension and with perfect ground and

stair clearance.

g. Test to check whether the wheelchair is able

to climb the very first step or not after fitting

the conveyer belts in their place.

For the purpose of proving the results of the

dynamical model and the stability analysis for

stairs-climbing, we perform a simulation

calculation and experiments on the developed

wheelchair robot. The structural parameters of the

robot are: the radius of the driving wheels is

R=250mm; the radius of the steering wheels and

the fixed wheels are both r=140mm; the length of

the bottom tracks is L=600mm; the front approach

angle is α=40°. The robot has two DC servo motors

with 400 watts power and the total mass of the robot

is m=62kg. The frictional factor between the tracks

and the sharp corner of the steps is 0.2.

According to the defined modes of motion, we

make a simulation calculation of the wheelchair’s

stairs-climbing experiments . In Figure 7, the

stability profile of wheelchair during the course of

its manoeuvre are best depicted in the profile

below :-](https://image.slidesharecdn.com/m6301074079-160728061528/75/Research-on-Optimization-Dynamics-and-Stability-of-Stairclimbing-Wheelchair-5-2048.jpg)

![Shashank Shekhar Sahoo et al. Int. Journal of Engineering Research and Applications ww.ijera.com

ISSN: 2248-9622, Vol. 6, Issue 3, (Part - 1) March 2016, pp.74-79

www.ijera.com 79|P a g e

Fig.7

The lowest point of stability during the robot’s

stairs-climbing occurs during those moments when

the driving wheels leave the ground and the

robot’s driving wheels roll over the first and

second steps. The main reason is that the driving

wheels are suddenly suspended in the air. This has

the result that the robot’s rolling fulcrum moves

forward substantially and thus it inclines to

tumble backwards more easily. This conclusion is

also proven in the tracked mobile robot’s stairs-

climbing experiments [5].

VII. CONCLUSION

Given a wheelchair the issue of how to ensure

stability in stairs-climbing is an important problem

which needed to be solved. Looking at this

problem, the dynamical model and the question of

stability during wheelchair’s stairs-climbing are

studied based on a mechanics analysis. The

acquired achievements can provide design and

analysis foundations for the wheelchair’ stairs-

climbing and solve the problem, which can be

summarized as follows:

(1) According to the requirement for stairs-

climbing, the mechanical structure of a

tracked mobile robot is designed and the

hardware composition of its control system is

given.

(2) Based on the analysis of the stairs-climbing

process, the dynamics model of the tracked

mobile robot during stairs-climbing is

established, which can provide fundamental

support for the stability analysis.

Fig. 8

The stability conditions for its stairs-climbing are

obtained. A quantitative evaluation method of the

stairs-climbing stability of the tracked mobile robot

is proposed and verified through simulation and

experiments.

This project will solve the issues faced by

physically challenged person through leg in day to

day life such as climbing staircase and having

additional security by averting collisions. This

project can be further extended to incorporate

feature like android application or wireless

technology based emergency message alert and

providing directional input to wheelchairs via icons

displayed in the smartphone screen. The emergency

notification will inform the relatives

instantaneously, thus providing safety and security

to the rider. This design can be used to carry heavy

objects in multistory buildings and military

surveillance purposes. It has the potential to play

active role in disaster management situations also.

References

[1] Hebert M H, Thorpe C E, Stentz A (1997)

Intelligent Unmanned Ground Vehicles.

Boston: Kluwer Academic Press. p. 310.

[2] Figliolini, G., and Ceccarelli, M. (2001).

Climbing stairs with EP-WAR2 biped

robot. IEEE International Conference on

Robotics and Automation, Seoul Korea, 4

4116-4121.

[3] Ben.Tzvi P, Ito S, Goldenberg A A (2007)

Autonomous Stair Climbing with

Reconfigurable Tracked Mobile Robot.

IEEE International Workshop on Robotic

and Sensors Environments, Ottawa,

Canada. pp. 16.

[4] Davids A (2002) Urban Search and

Rescue Robots: From Tragedy to

Technology. Intelligent System of IEEE.

17(2): 81-83.

[5] Birk A, Carpin S (2001) Rescue Robotics

a Crucial Milestone on the Road to

Autonomous Systems.Advanced Robotics

Journal. 20(5): 595-576.](https://image.slidesharecdn.com/m6301074079-160728061528/75/Research-on-Optimization-Dynamics-and-Stability-of-Stairclimbing-Wheelchair-6-2048.jpg)