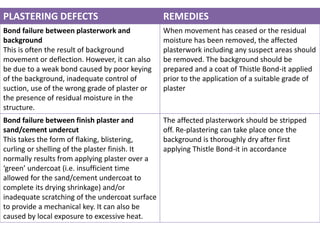

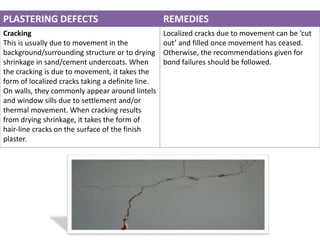

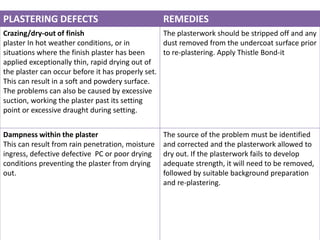

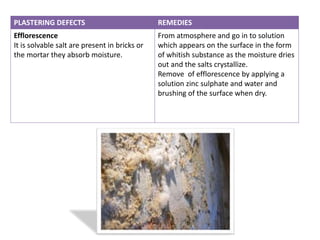

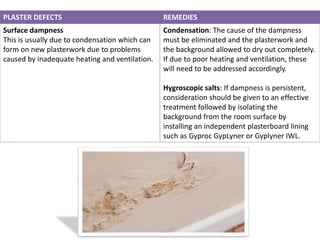

This document provides an overview of case studies, specifically focusing on the process of plastering, which includes materials, types, advantages, and disadvantages. It also addresses common defects in plastering and their remedies, emphasizing the importance of identifying underlying issues before reapplication. Additionally, it outlines various finishing techniques and the implications of environmental factors on plasterwork integrity.