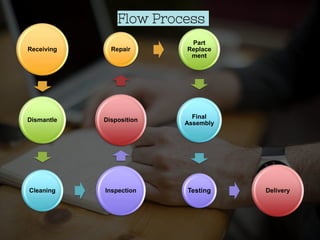

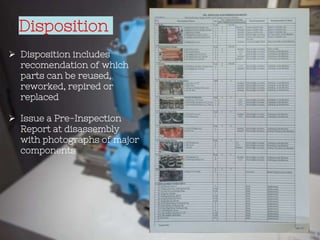

The document outlines the repair cycle for a blow out preventer (BOP). The process involves receiving the BOP, dismantling and inspecting components, cleaning parts, making any necessary repairs or replacements, reassembling, testing, and delivering the repaired BOP. Key steps include dismantling while noting problem areas, cleaning via sandblasting, visually and dimensionally inspecting parts, replacing components that exceed limits, post-weld heat treatment of repaired parts, pressure and hydraulic testing the reassembled BOP, and delivering the repaired BOP according to specifications.