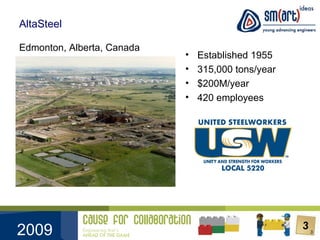

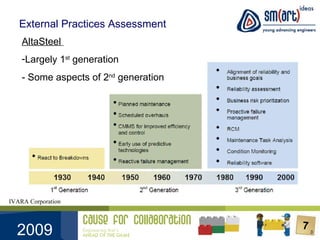

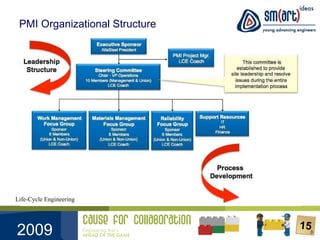

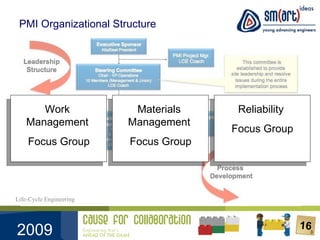

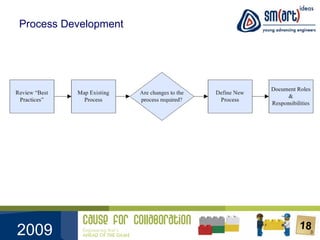

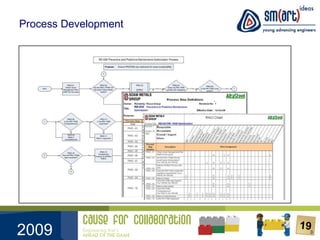

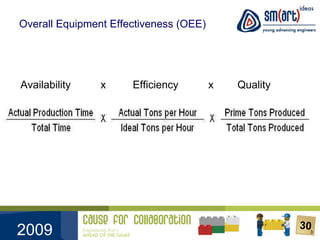

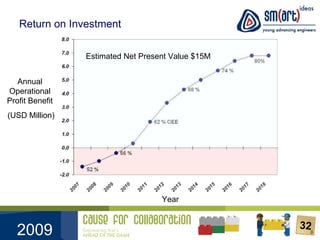

AltaSteel is a steel plant in Edmonton, Alberta, Canada seeking to improve equipment performance and reduce costs through a Proactive Maintenance Initiative (PMI) focusing on reliability culture change and continuous improvement. The PMI involves a joint effort between management and the union to implement reliability best practices through focus groups, new roles, training, and asset management software. Initial results include improved skills, collaboration, processes, and overall equipment effectiveness, with an estimated $15 million return on investment over time.