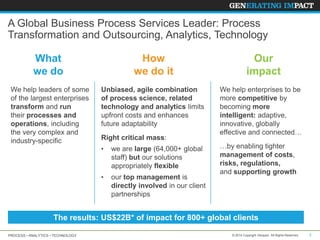

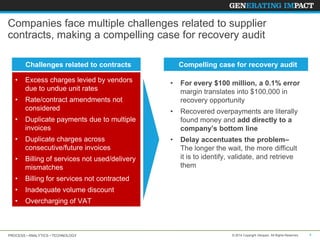

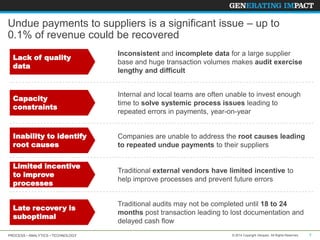

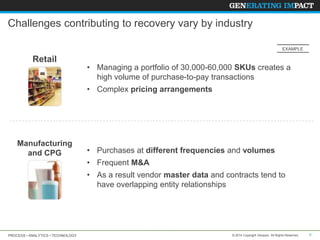

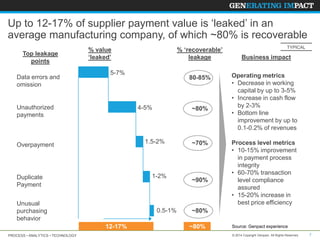

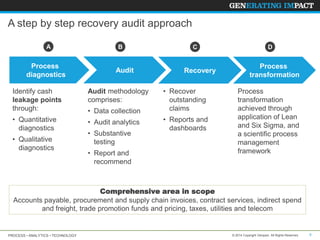

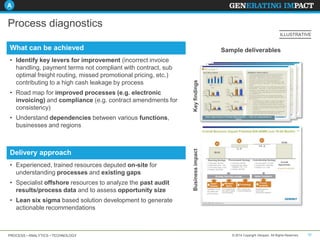

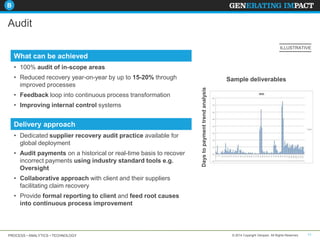

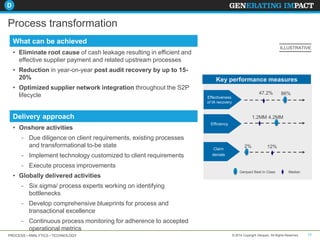

The document outlines Genpact's recovery audit services aimed at recovering excess payments from suppliers through analytics and process improvement. It discusses the challenges companies face regarding supplier contracts, highlighting potential financial recovery opportunities, and details a step-by-step approach for conducting audits and transforming processes. The ultimate goal is to enhance competitiveness by enabling better cost and risk management while identifying and rectifying inefficiencies in supplier payments.

![Thank You

Gianni.giacomelli[at]genpact.com

Subhashis.nath[at]axisindia.co.in

www.genpact.com/home/solutions/finance-accounting/recovery-audit-services](https://image.slidesharecdn.com/recoveryauditservices-overviewslideshare-140227064503-phpapp02/85/Recovery-audit-services-16-320.jpg)