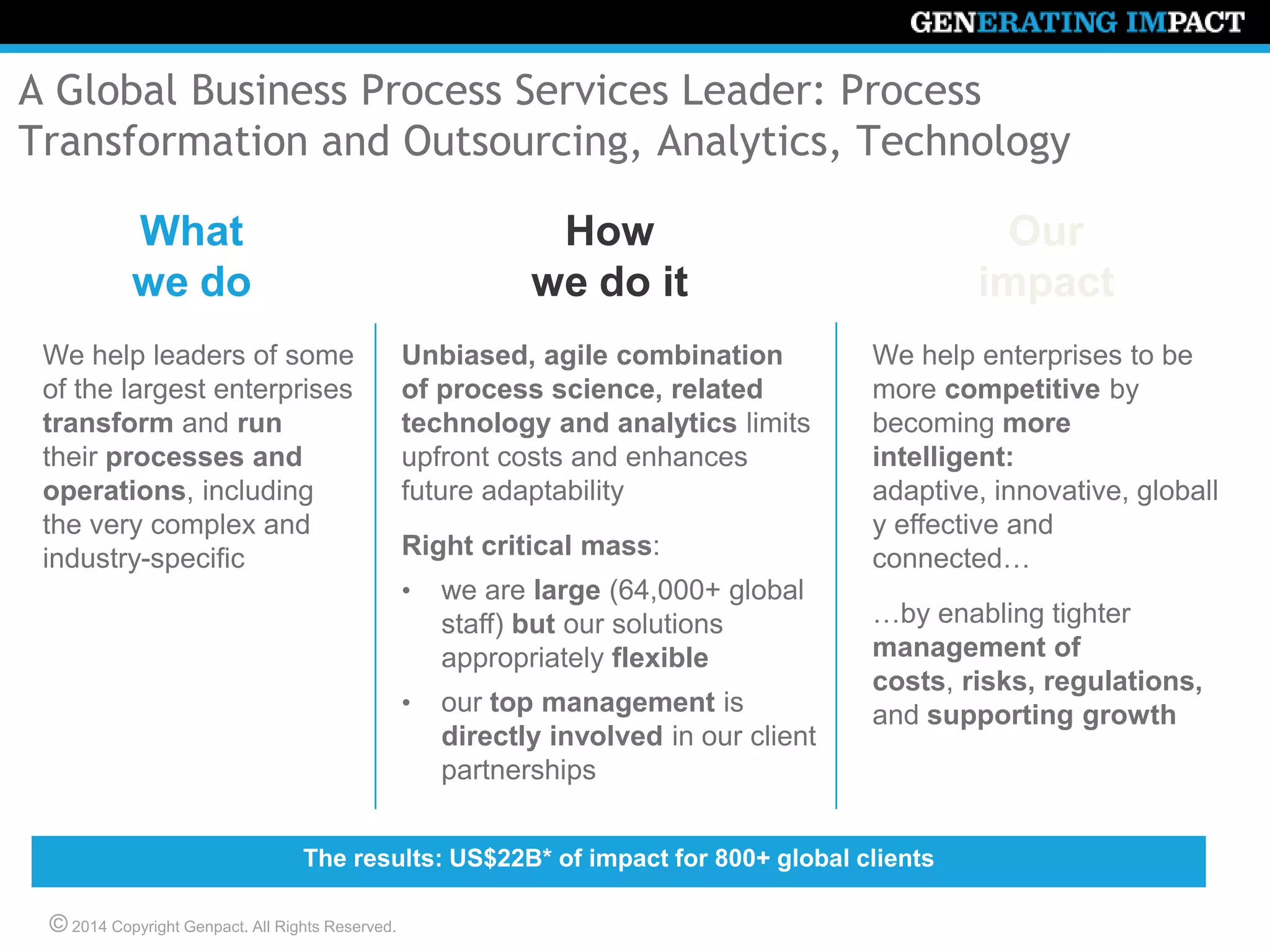

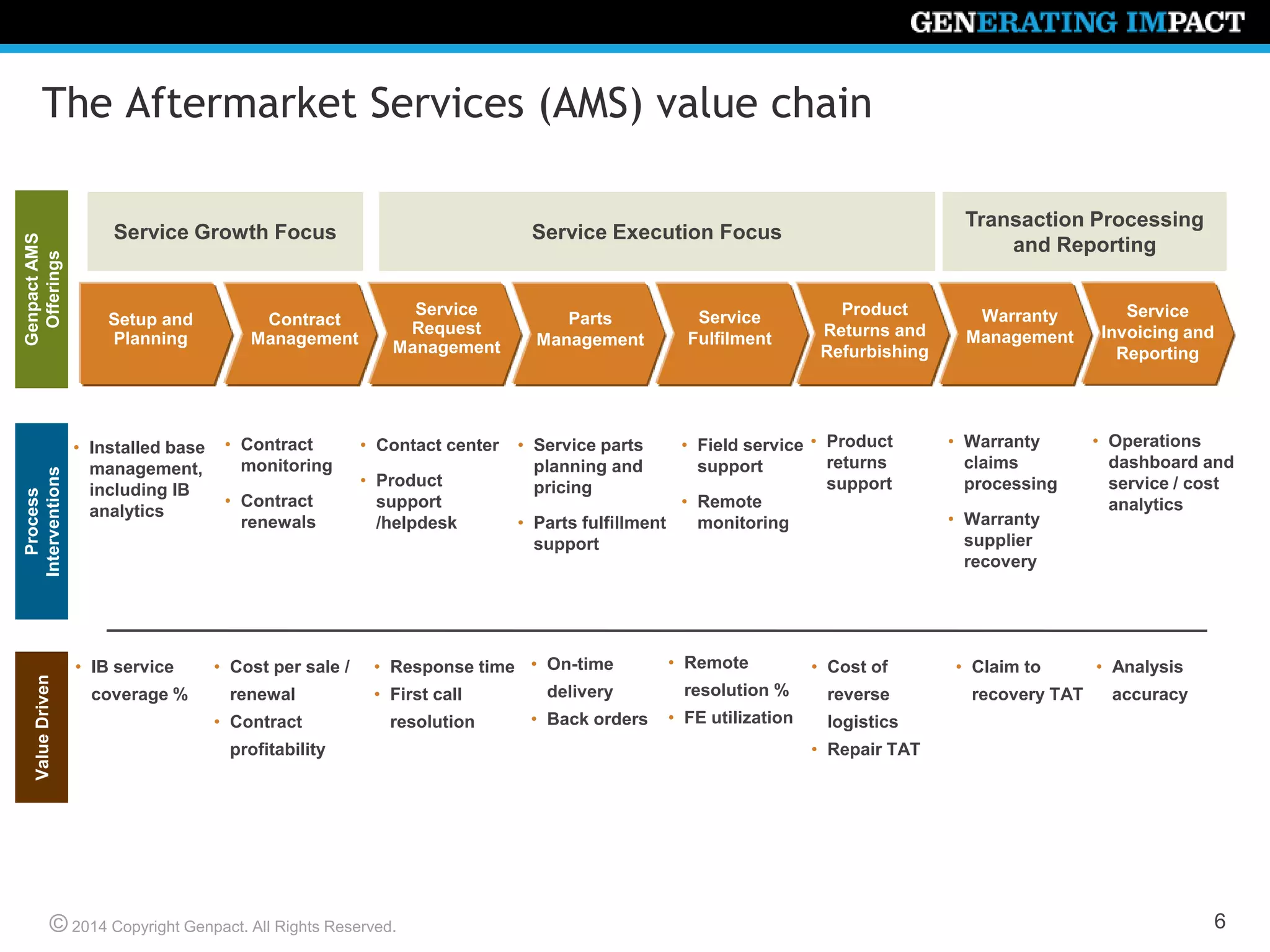

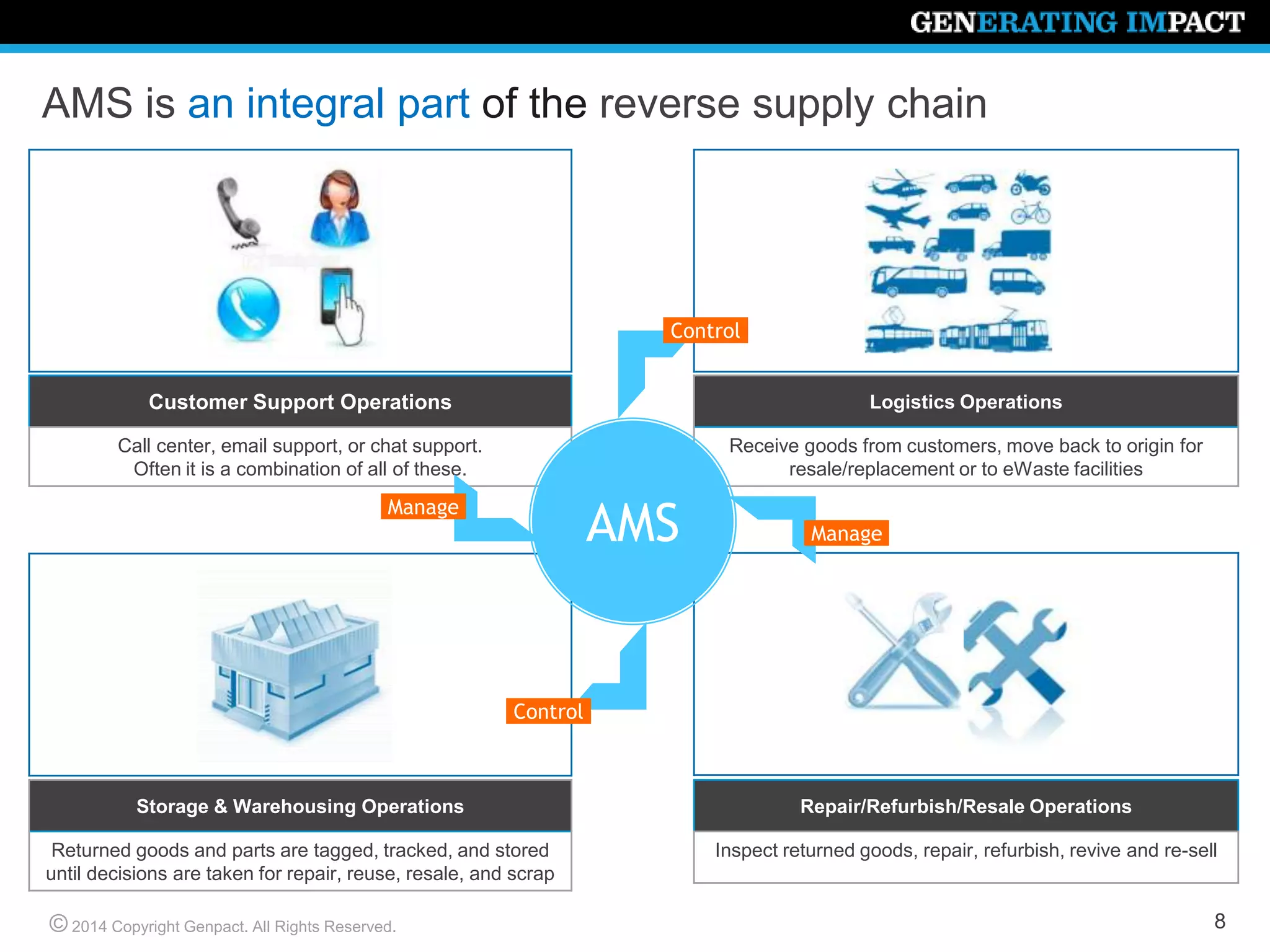

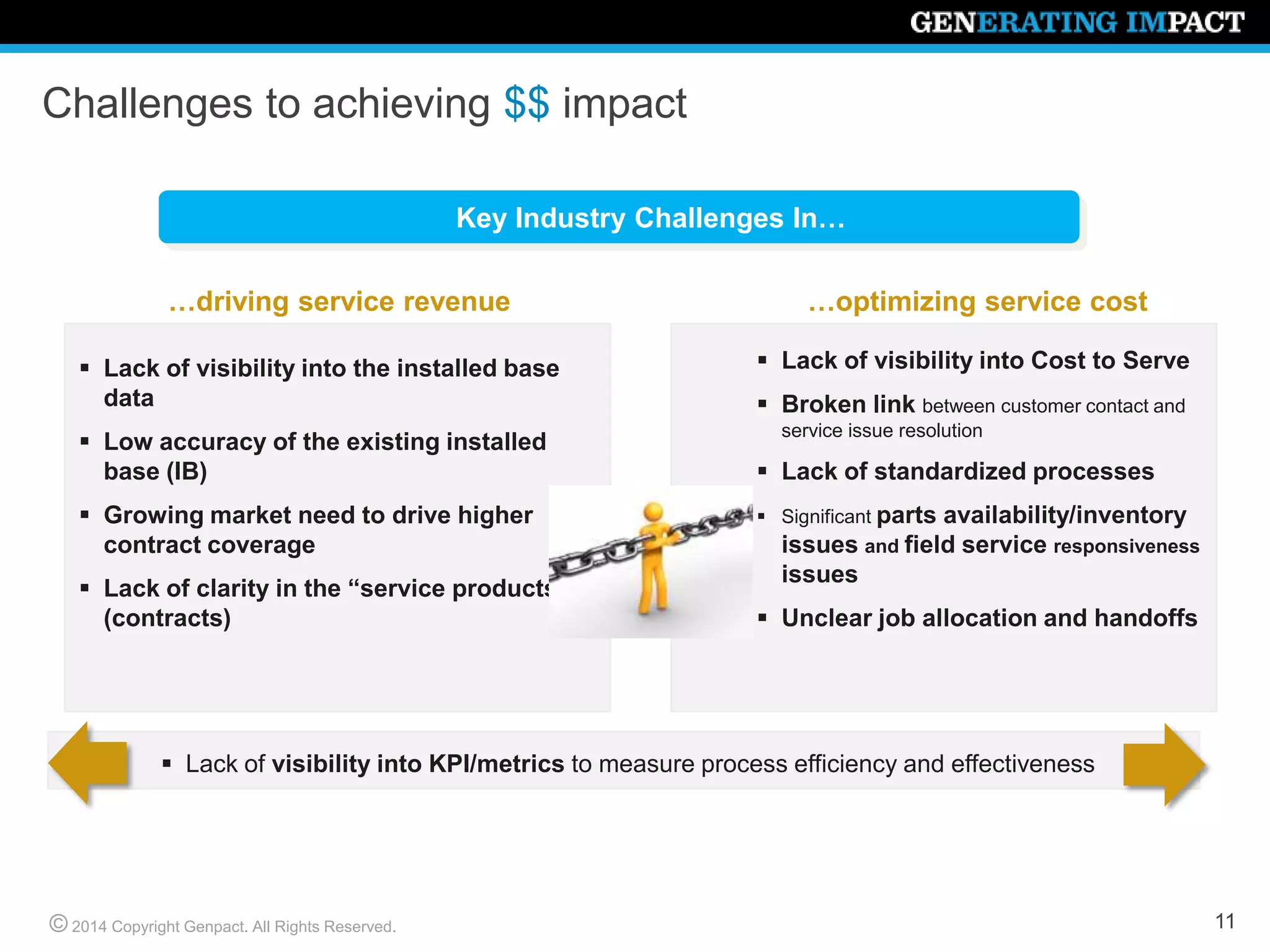

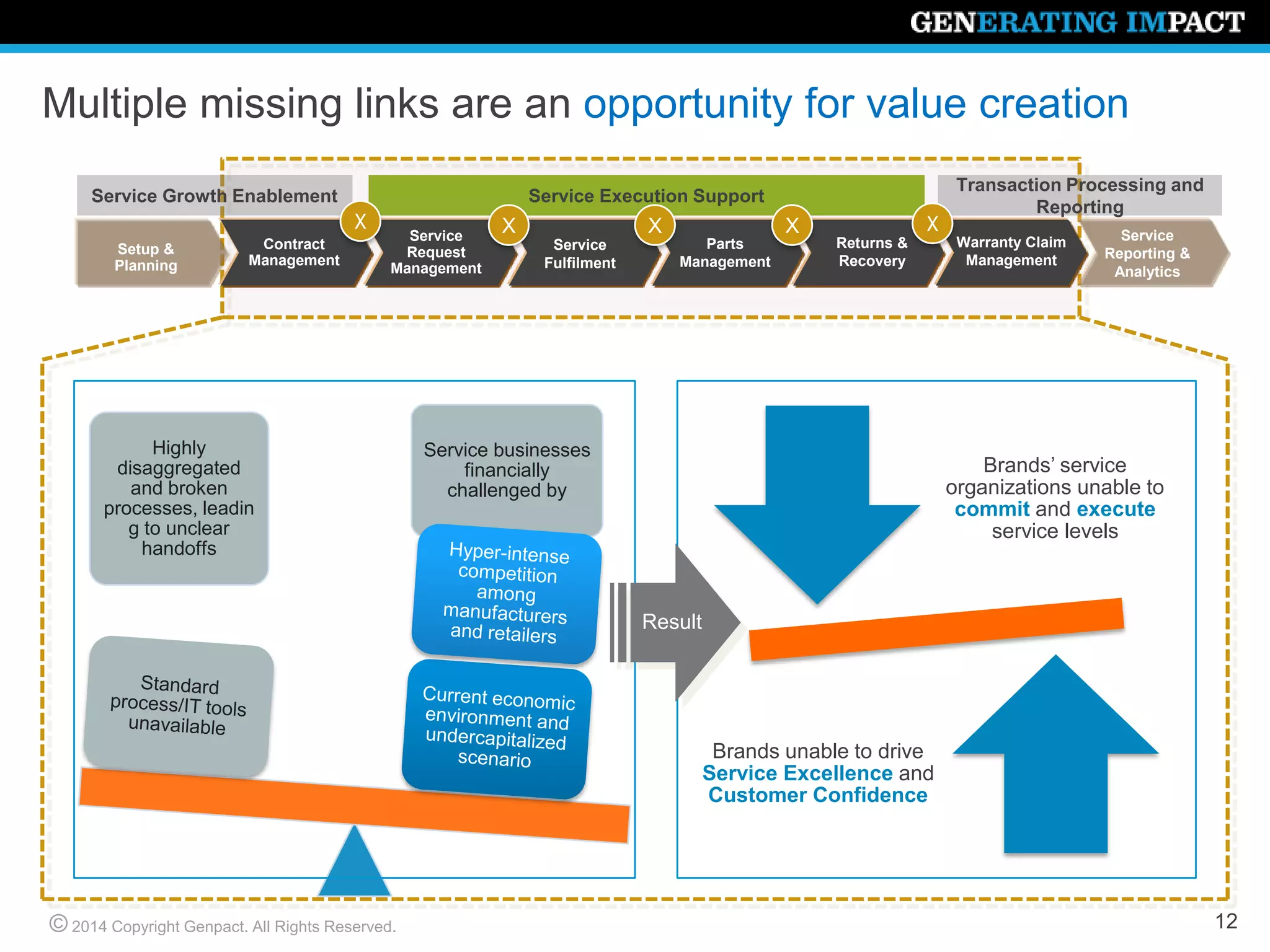

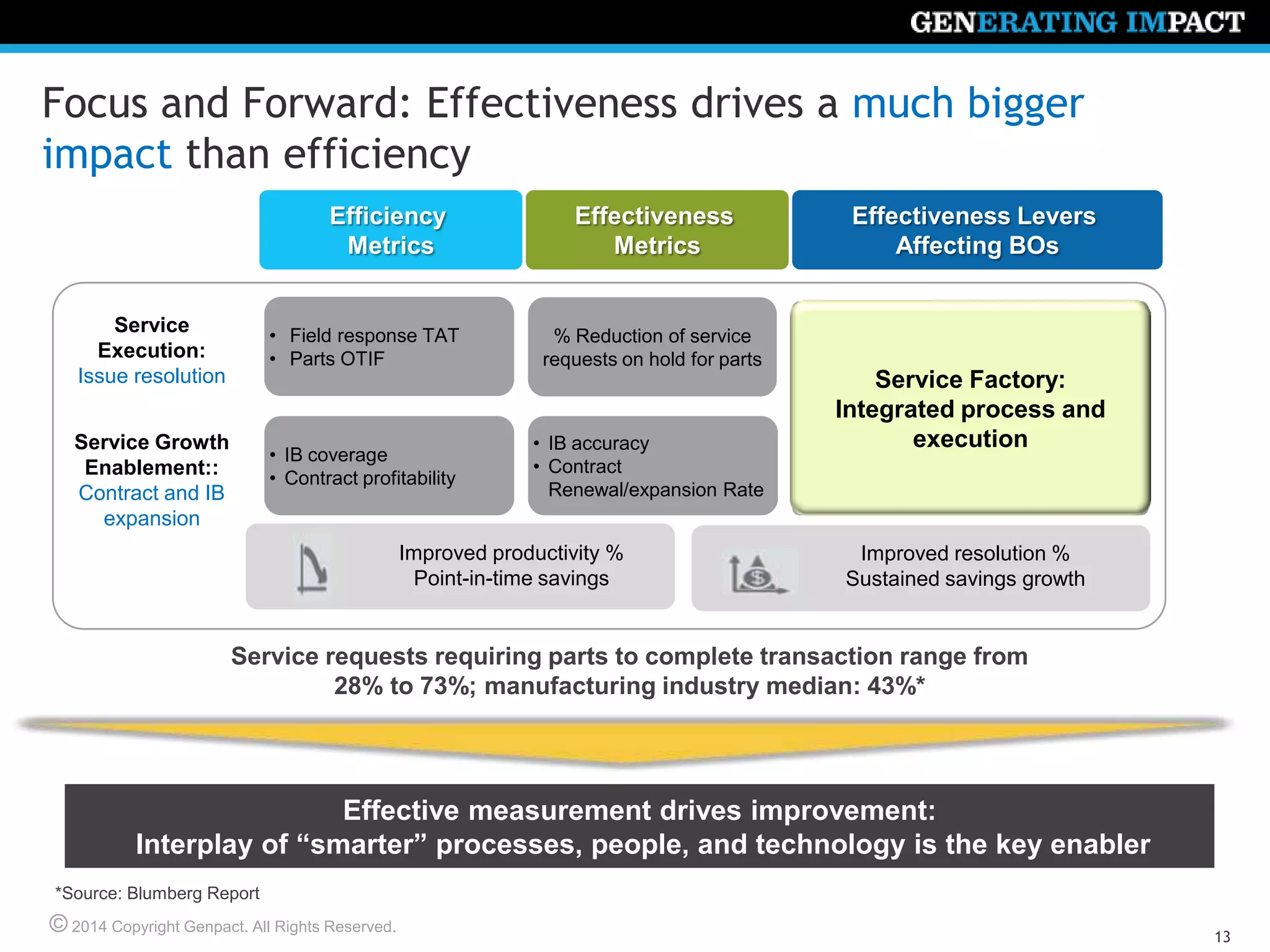

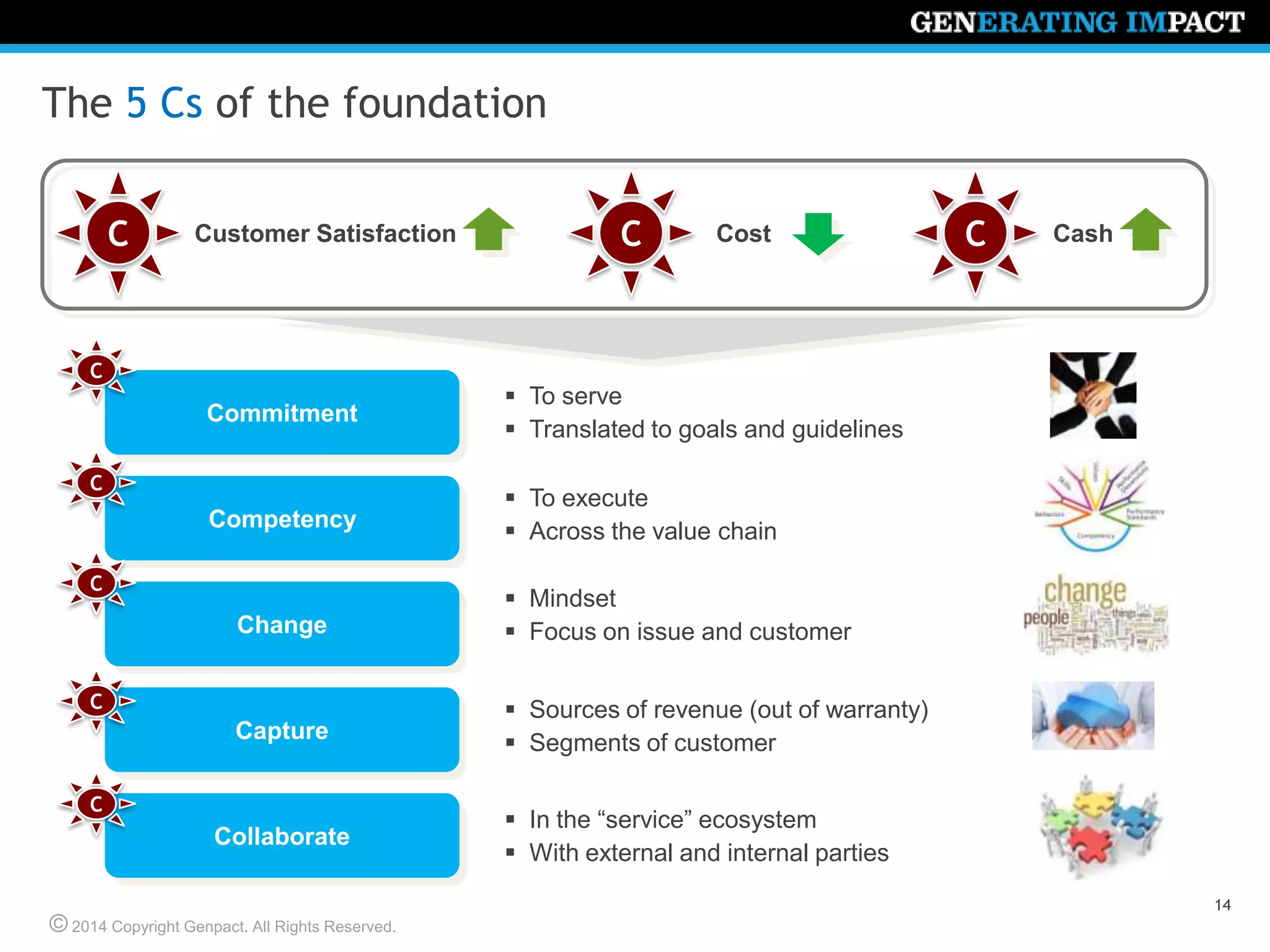

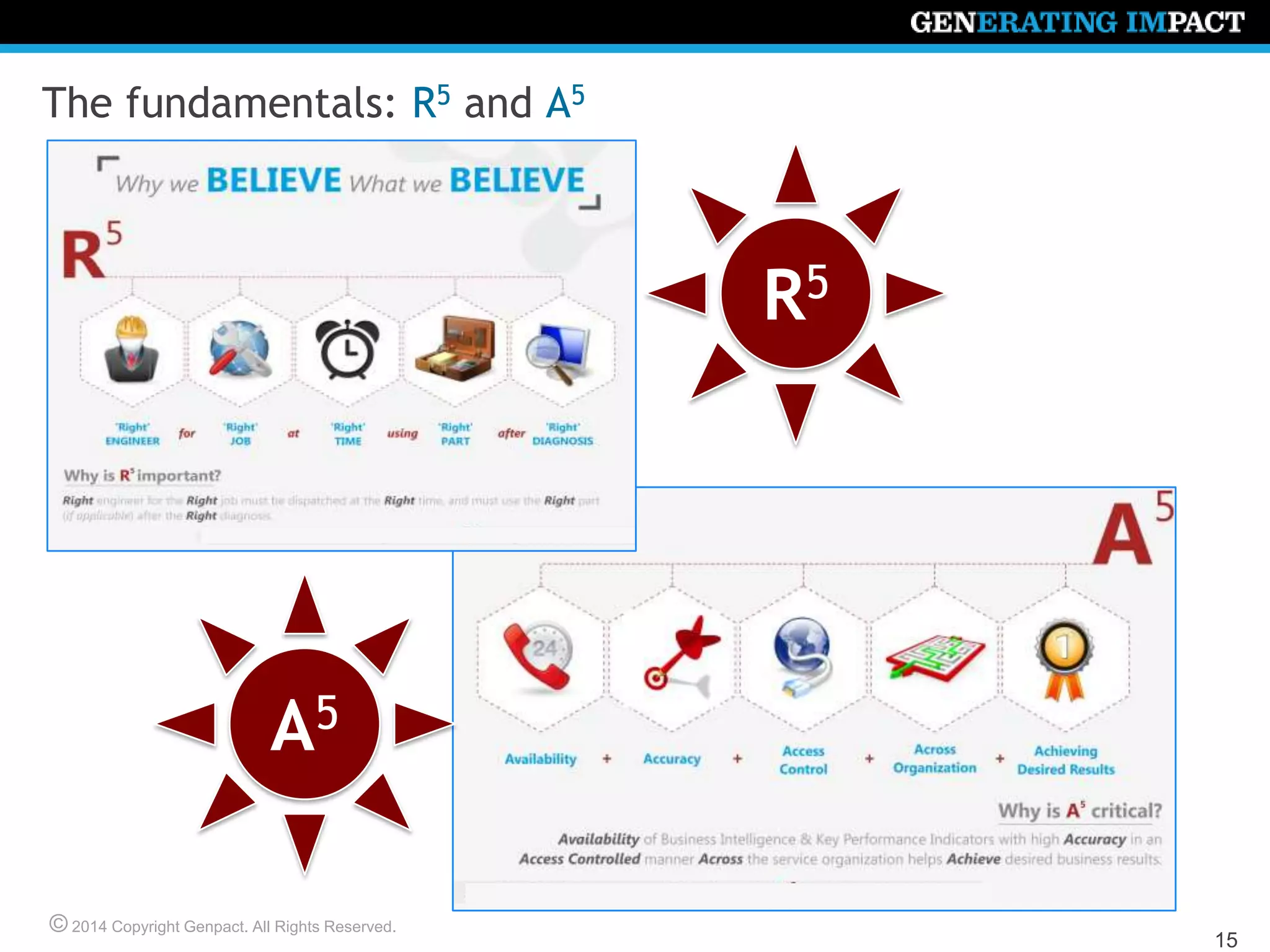

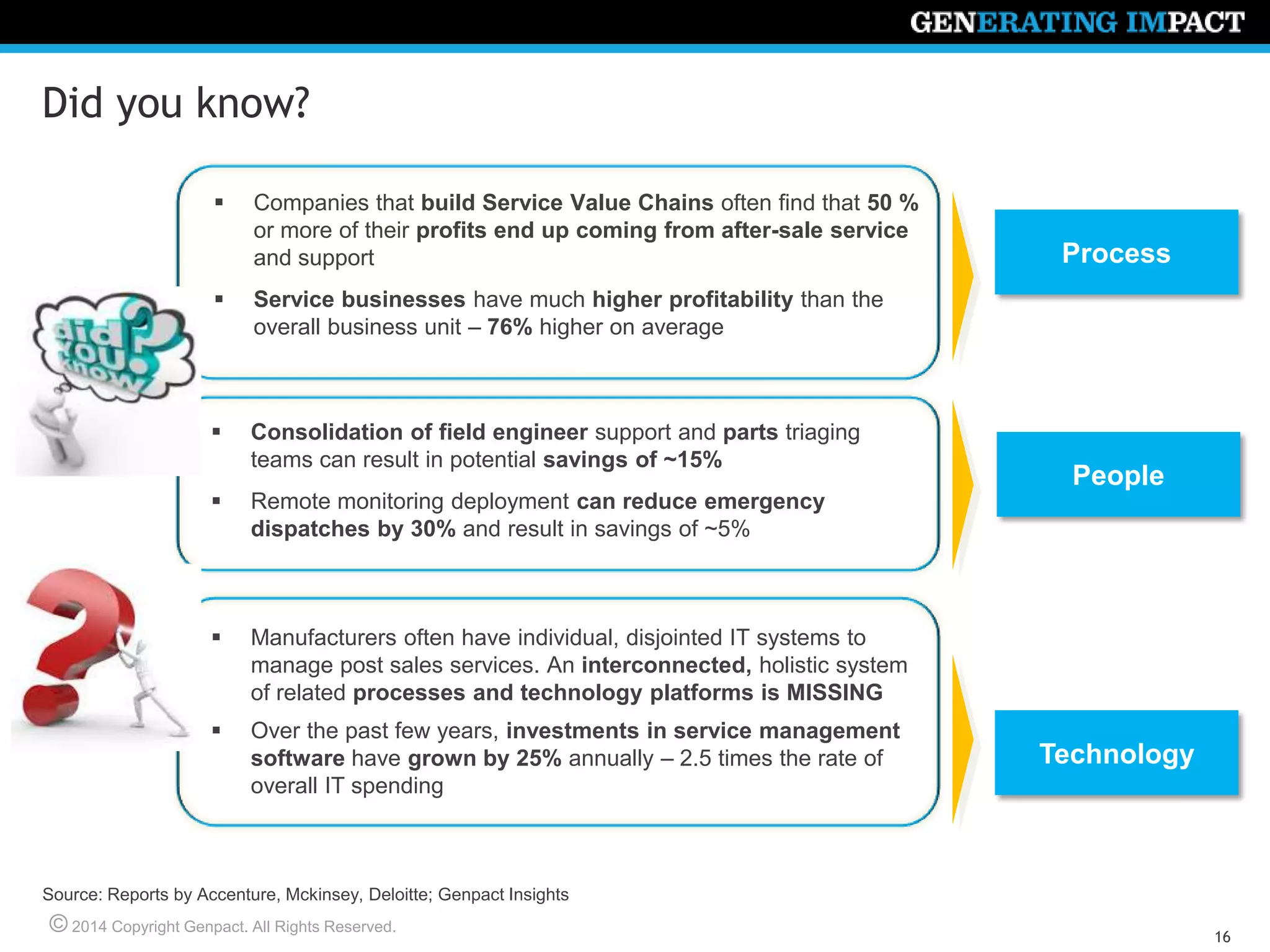

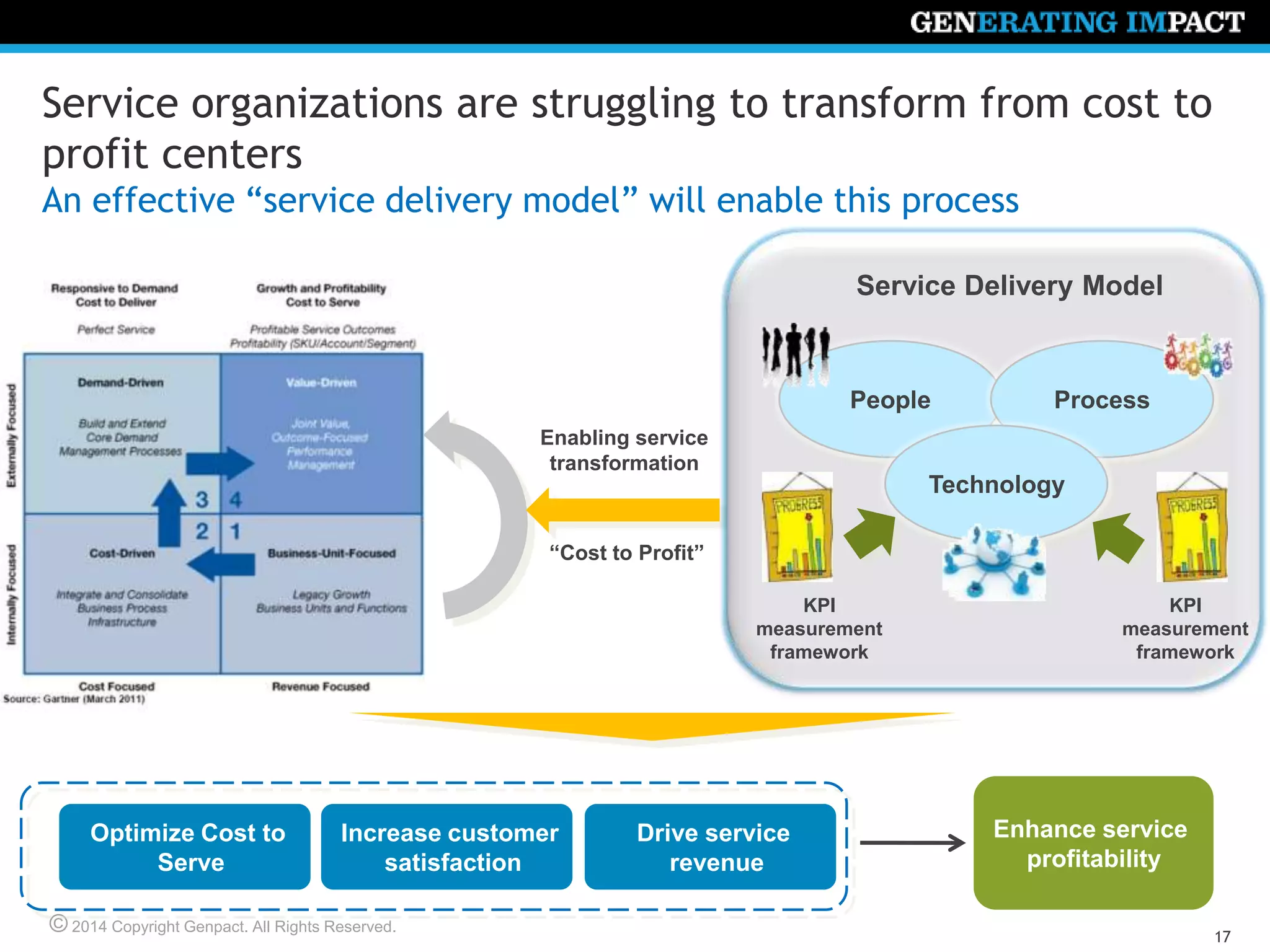

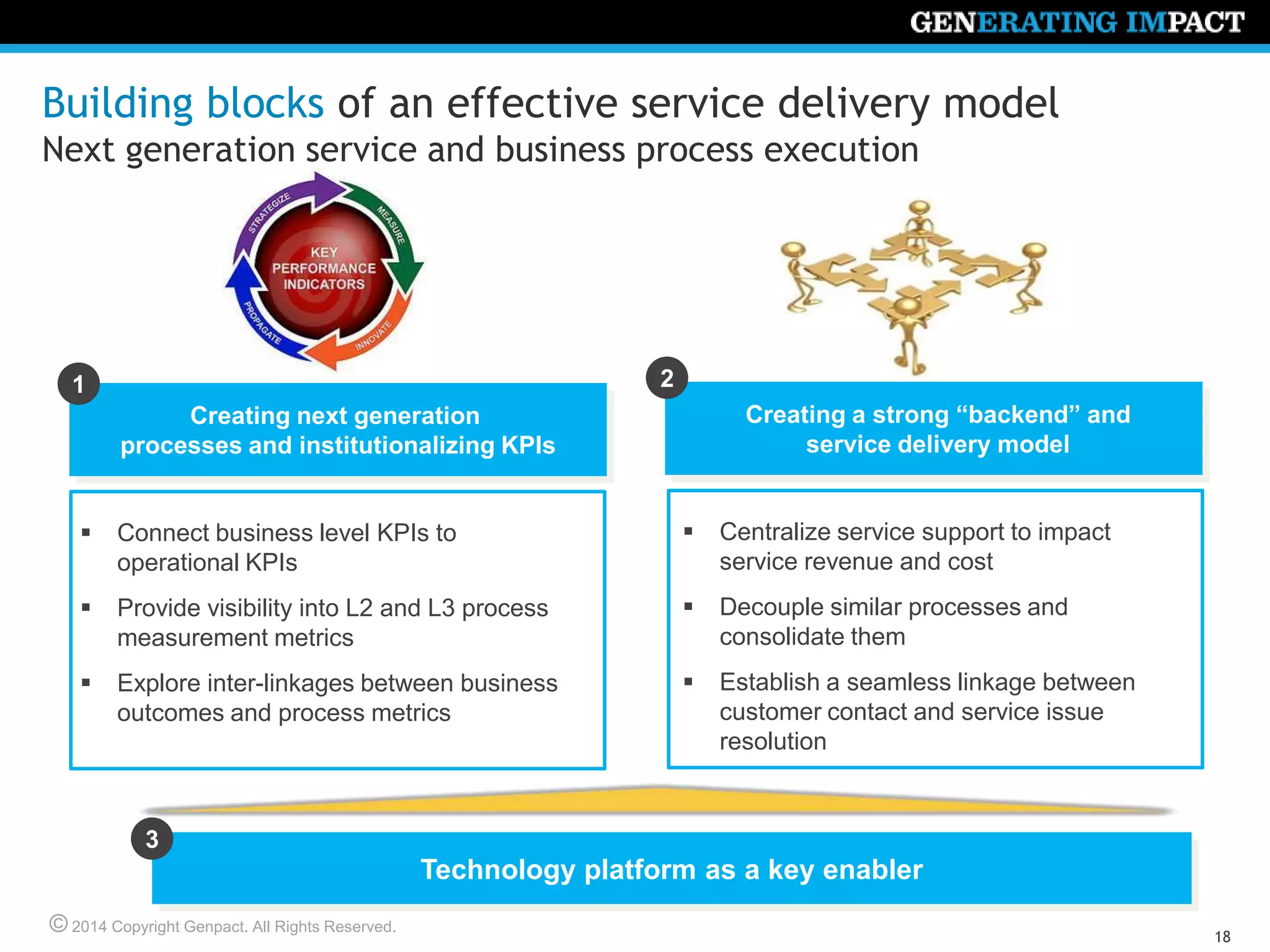

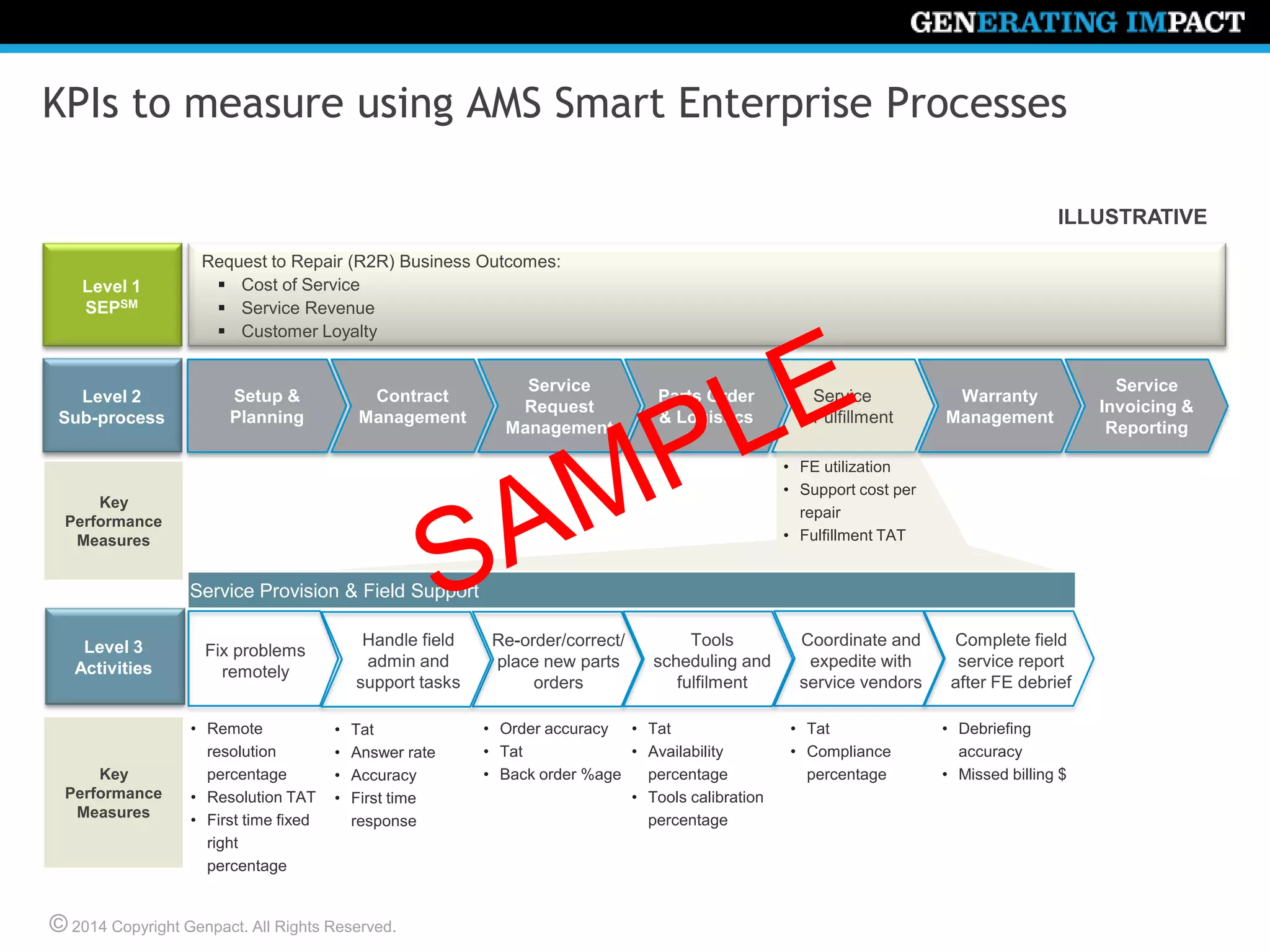

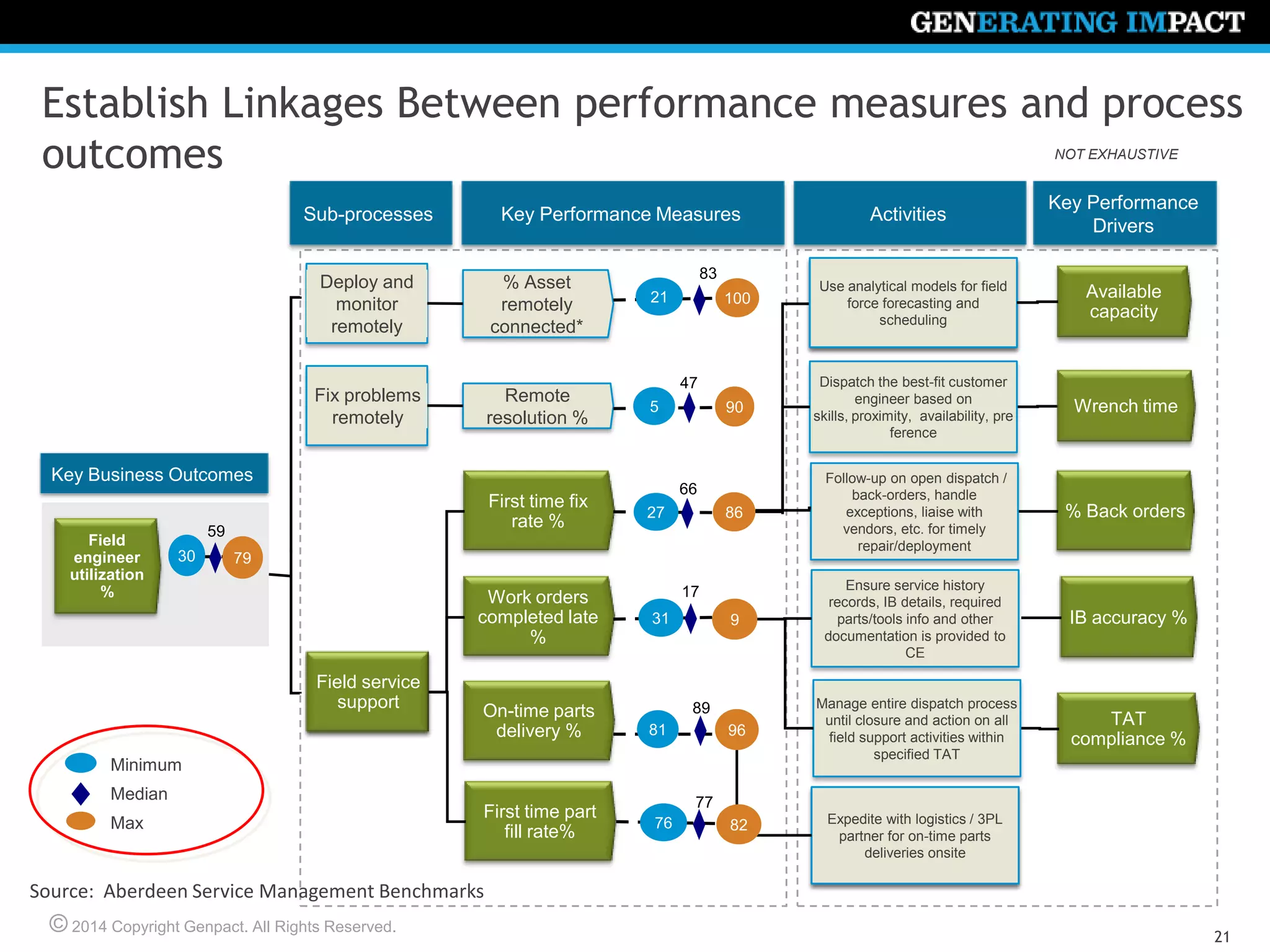

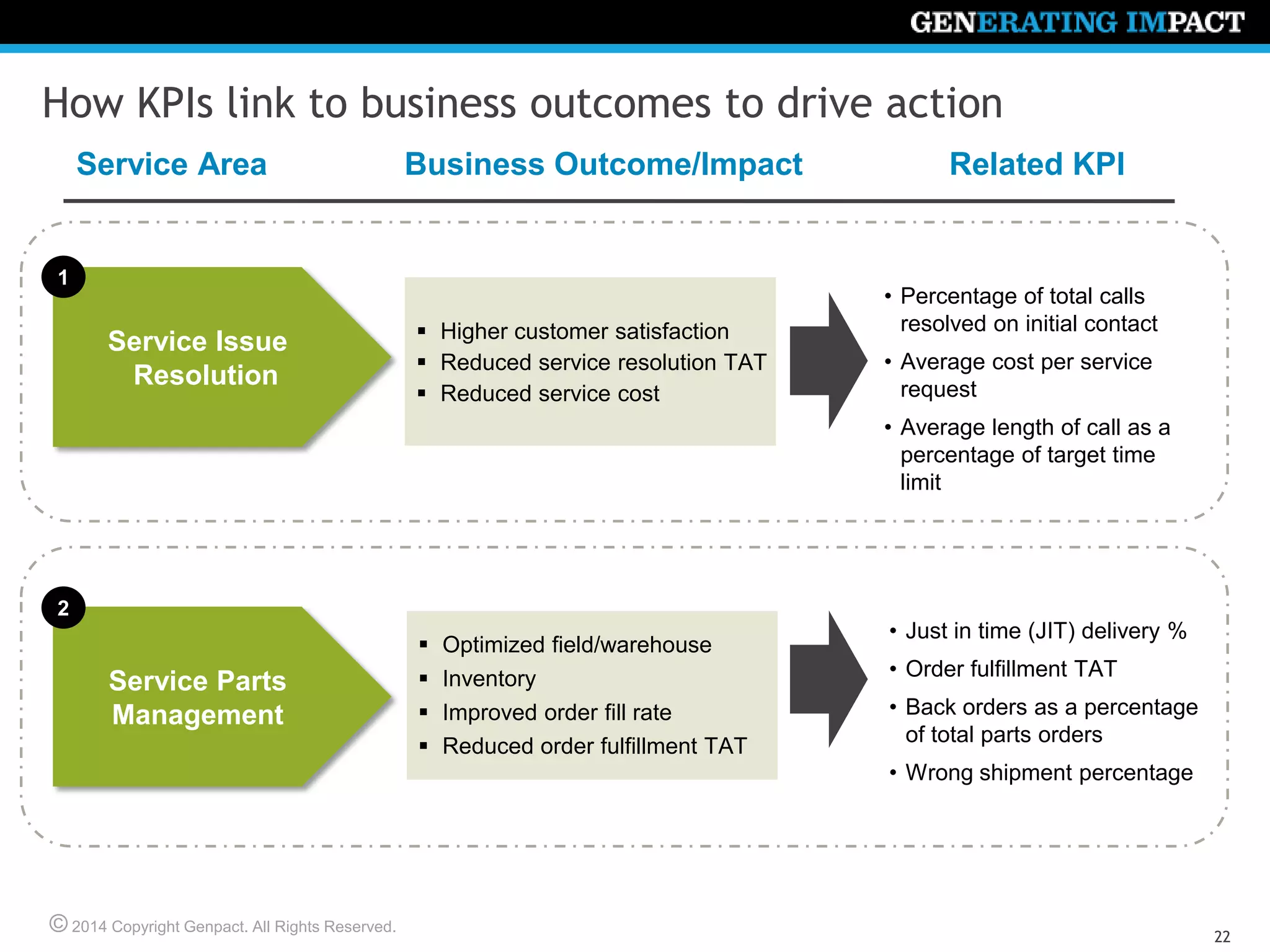

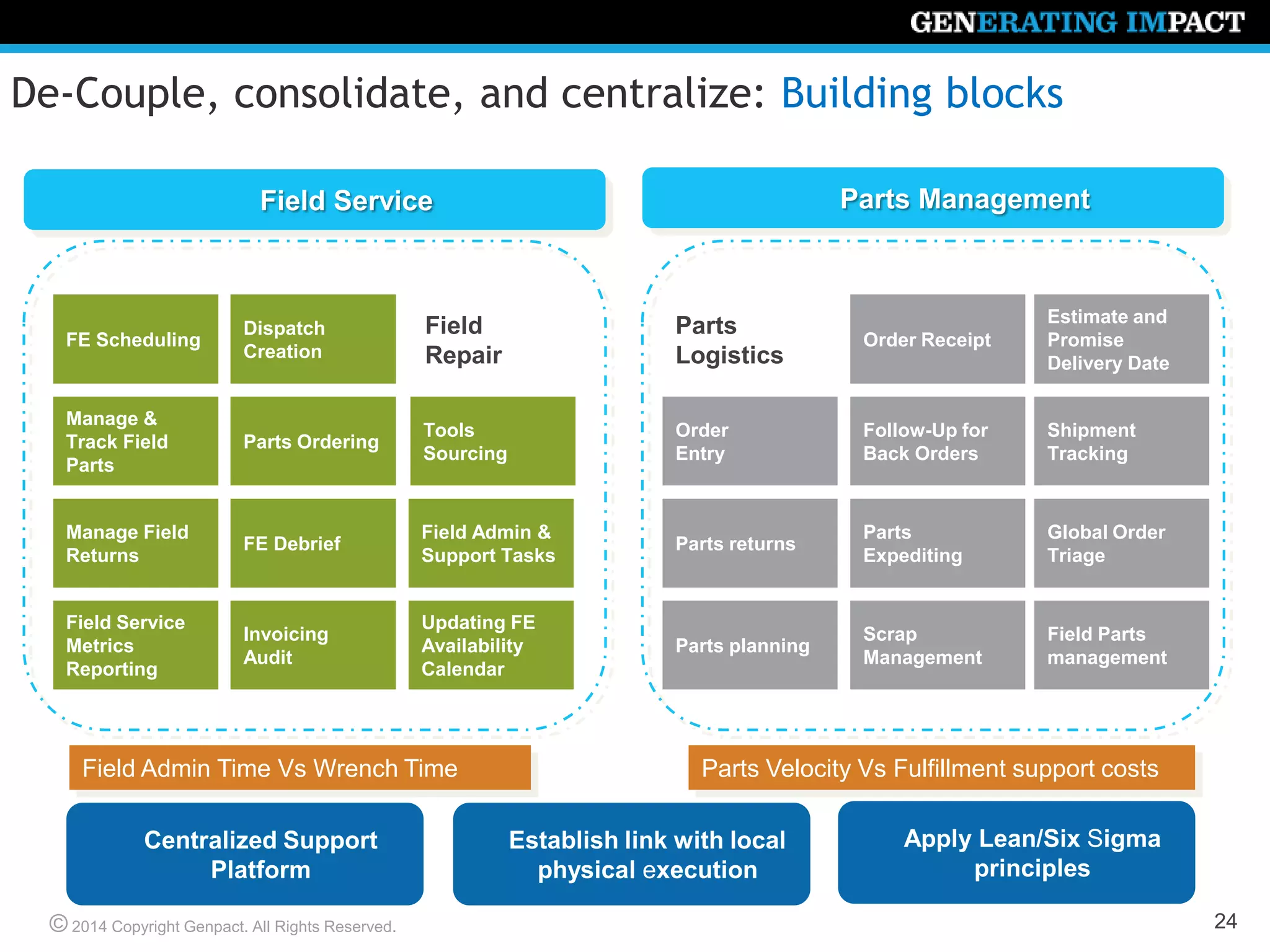

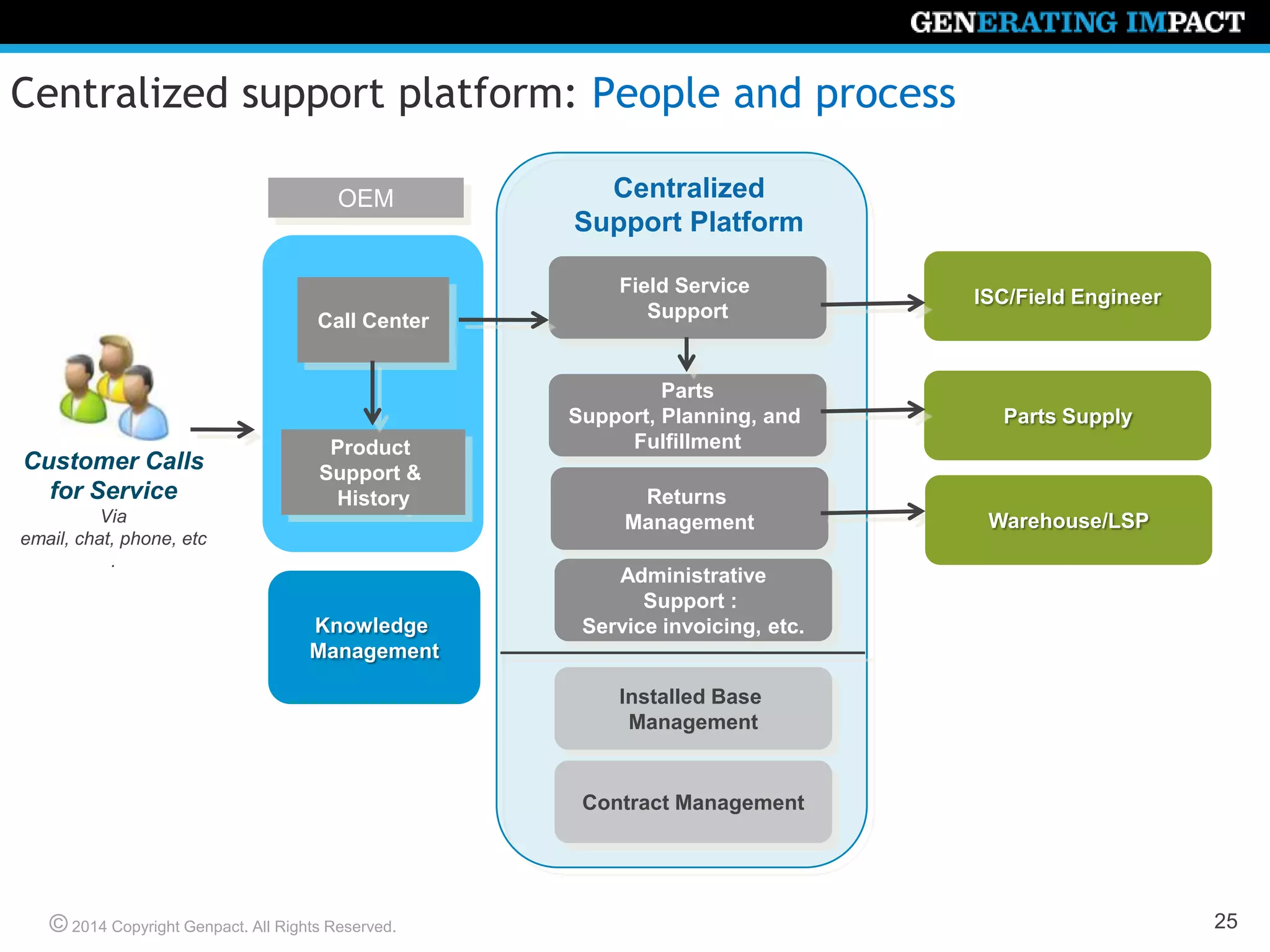

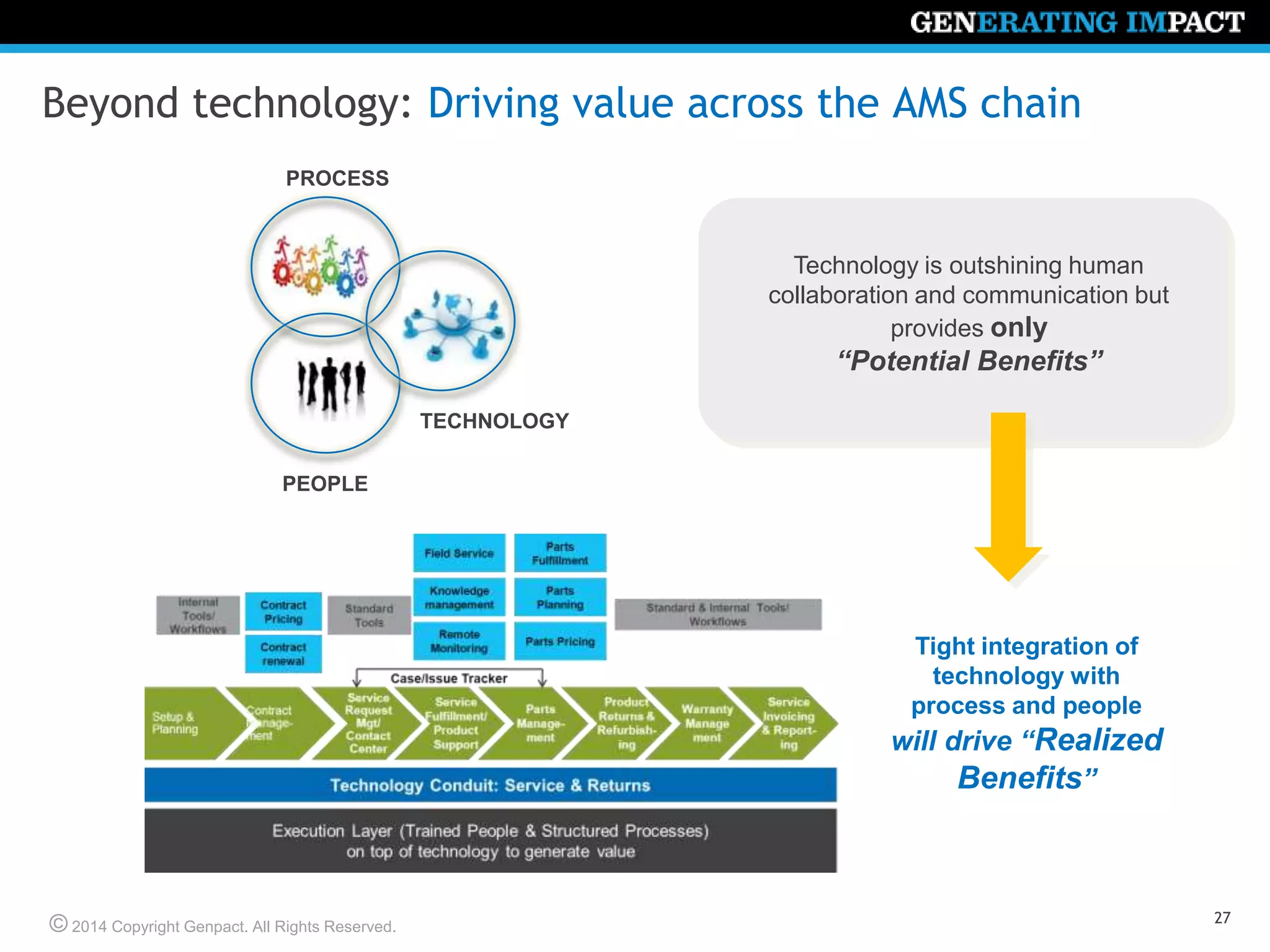

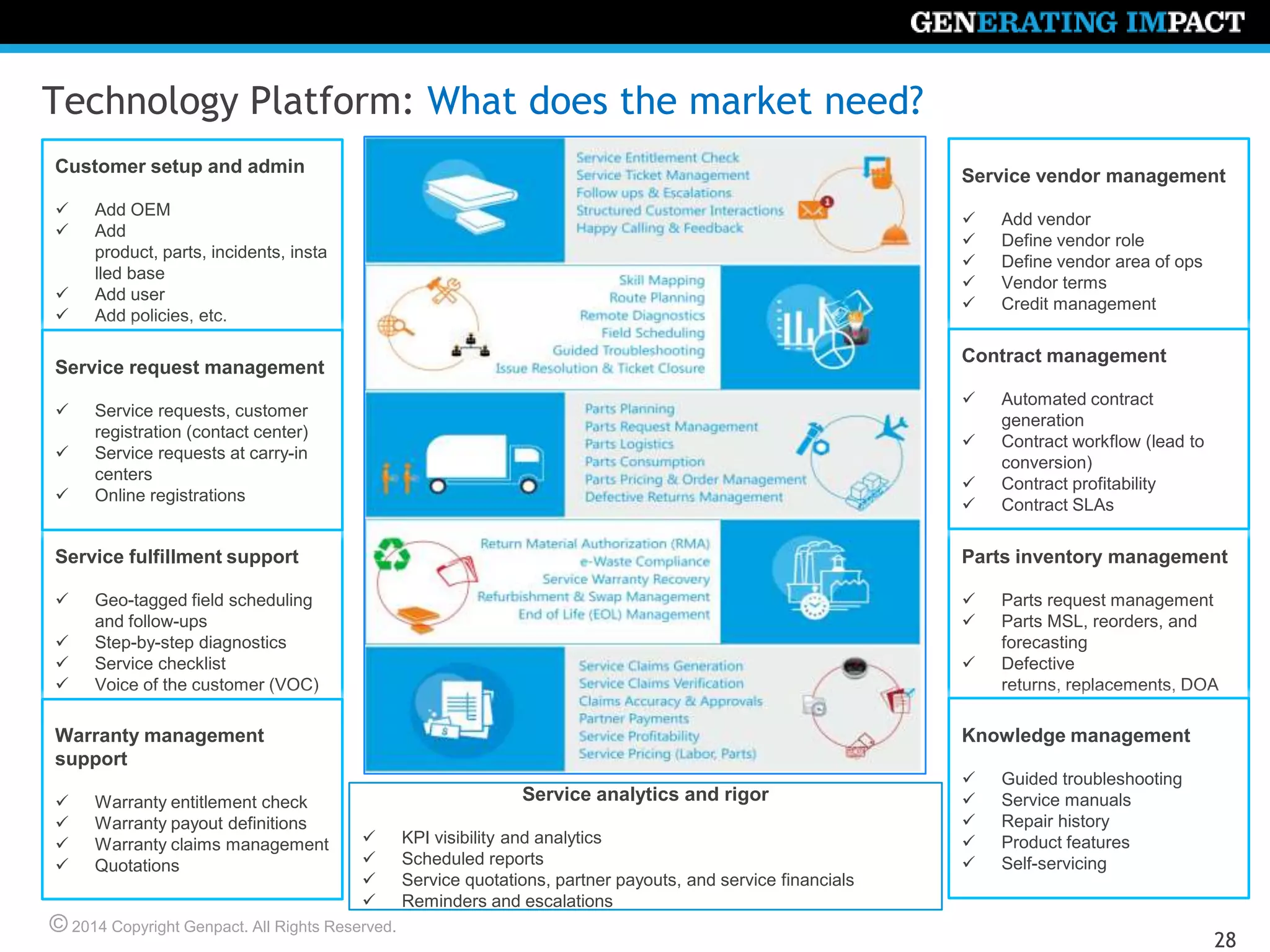

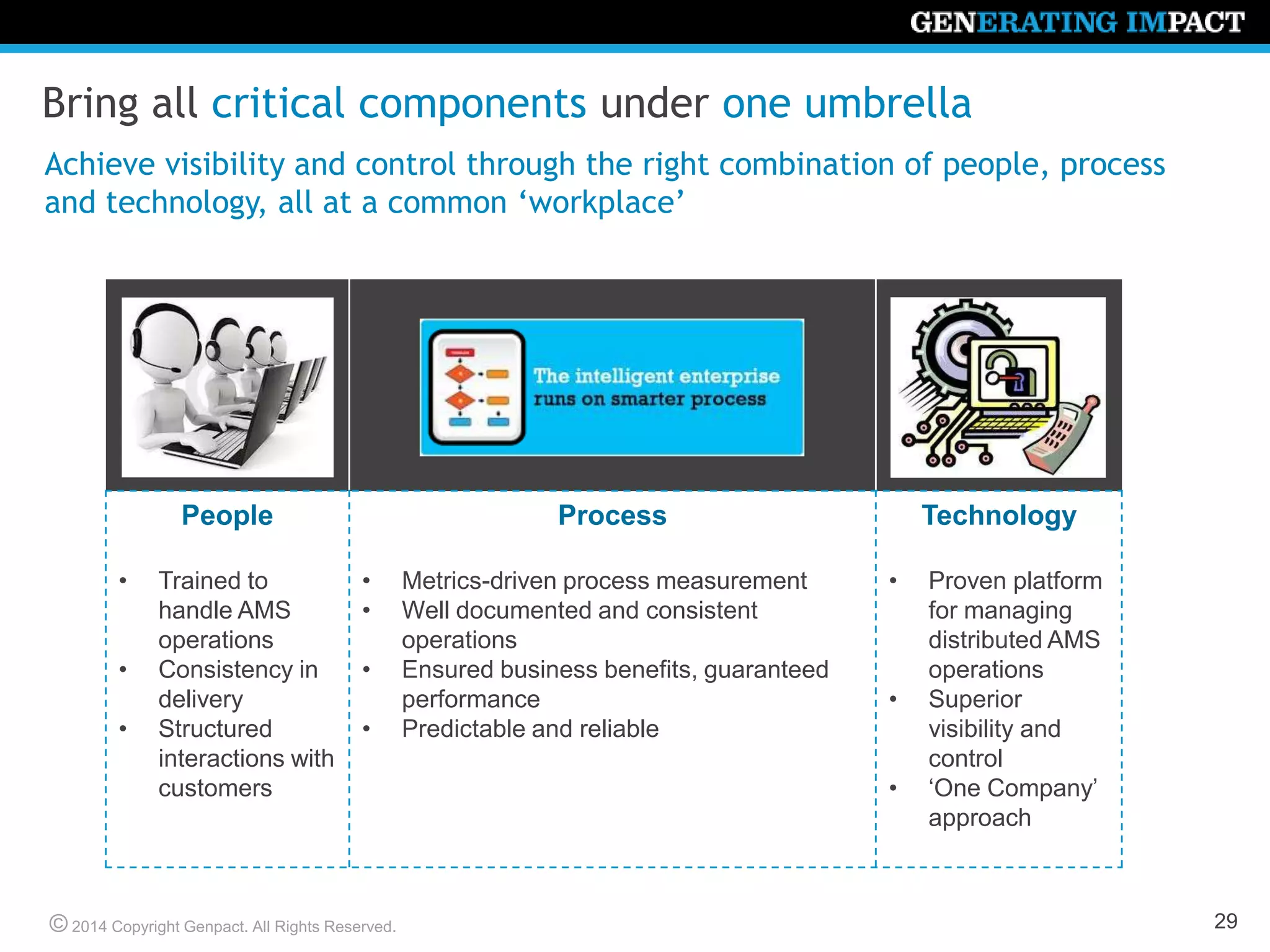

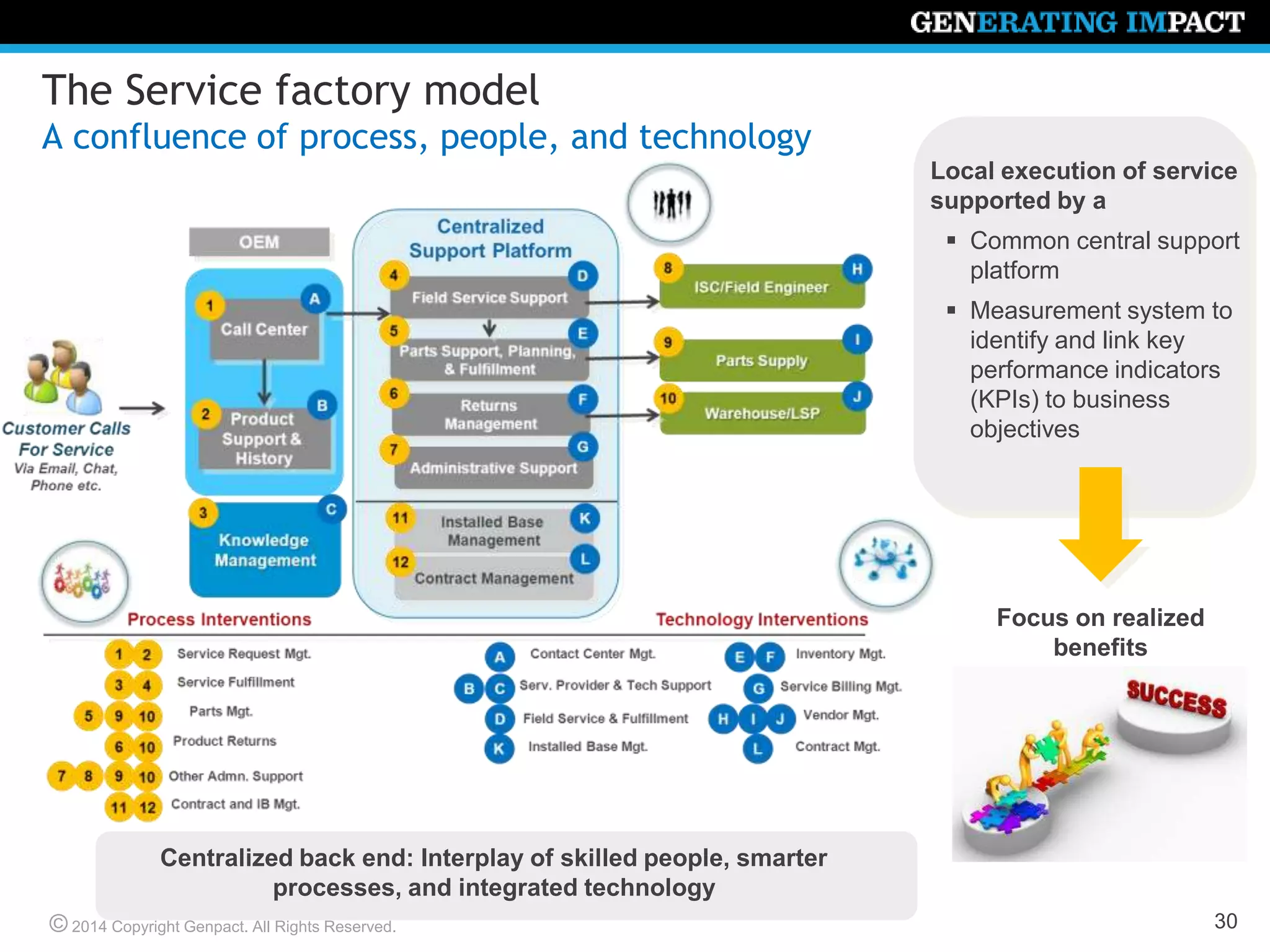

The document discusses building an effective service delivery model for aftermarket services. It suggests implementing key performance indicators centrally and creating next generation processes to optimize cost to serve, increase customer satisfaction, drive service revenue, and enhance service profitability. It also recommends creating a strong backend and service delivery model by de-coupling, consolidating, and centralizing processes. Finally, it positions technology as a key enabler when tightly integrated with processes and people to drive realized benefits across the aftermarket services value chain.